In a significant advancement for the wastewater treatment industry, GN Separation has recently completed the manufacture of a GNDL402 Sludge dewatering screw press and a set of chemical dosing unit, which will be delivered to a European client. Continue reading

Category Archives: Solids Control

High Shearing-force Circular Screen for Overseas Silicon Sand Classification Project

News from GN Separation this week: Recently, 1 set of High Shearing-force Circular Screen has been manufactured and is ready to start serving for an overseas Silicon Sand Classification project.

The features of GN High Shear Circular Screen are as below:

- GN Separation‘s high shear circular screen utilizes a single vibration motor as the power source, inducing circular motion in the screen deck.

- Equipped with imported vibration motors (Martin or OLI) featuring advanced technology, ensuring reliable operation and prolonged trouble-free service life.

- The screen box assembly is divided into multiple sections, offering benefits such as high processing capacity, superior screening efficiency, minimal power consumption, reduced dynamic load, straightforward operation, consistent performance, safety, durability, and low maintenance requirements.

- Convenient and dependable mechanical angle adjustment of the screen box assembly. Reconstituted-slurry spray water is introduced between each section of the screen deck to enhance material screening effectiveness.

- The screen box undergoes comprehensive heat treatment to withstand prolonged operation under high vibration intensity.

- Utilizes internationally renowned electrical components from Siemens or Schneider.

- Features flexible polyurethane screen mesh with excellent elasticity, minimizing screen blockage. Installation of 4 to 5 screen panels is possible.

- The screen is secured using mesh-pulling bolt components, ensuring ease of operation and reliable fastening.

- Surface treatment of the vibrating screen incorporates sandblasting technology and heavy anti-corrosion paint spraying, offering excellent corrosion resistance. The material contact surface is coated with a wear-resistant polyurea resin layer or fitted with wear-resistant rubber plates to safeguard the screen machine’s surface and extend its operational lifespan.

To ensure that’s this High Shear Circular Screen will deliver reliable performance and that all parts and components operate smoothly for long-term usage, our technical, production, and quality control departments have meticulously focused on material selection, preparation, every production step, and inspections at each stage

Should you require any assistance regarding the operation and maintenance of Mud Solids Liquid Separation Equipment, such as vibrating screen, Mud tank, Desilter, Desander Unit, Decanter Centrifuge, please feel free to contact GN Separation. Our engineers possess the best experience and knowledge in the relevant industry, and we are committed to providing optimal support for your project. Establishing stable and long-term cooperation is our goal, and we offer online support and on-site instructions tailored to specific situations if needed.

GN High Frequency Fine Vibrating Screen for Overseas Golden Mining

News from GN company this week: Recently, 1 set of high-frequency fine Vibrating Screen has been manufactured and is ready to start serving for an overseas golden mining project.

The model number of this set of high-frequency fine Vibrating Screen is GNFG1028.

To ensure that’s this high-frequency fine Vibrating Screen will deliver reliable performance and that all parts and components operate smoothly for long-term usage, our technical, production, and quality control departments have meticulously focused on material selection, preparation, every production step, and inspections at each stage.

Should you require any assistance regarding the operation and maintenance of Construction Mud Solids Liquid Separation Equipment, such as Vibrating Screen, Mud tank, Mixer, Centrifugal pump, mud cleaner, feel free to contact GN company. Our engineers possess the best experience and knowledge in the relevant industry, and we are committed to providing optimal support for your project. Establishing stable and long-term cooperation is our goal, and we offer online support and on-site instructions tailored to specific situations if needed.

As a leading manufacturer of separation and conveying equipment, GN consistently prioritizes product quality, considering the long-term benefits for our users. In the Decanter centrifuge field, GN is a professional manufacturer that meticulously selects raw materials, utilizing high-quality centrifugal casting or forging stainless steel materials. For wearing parts, hard alloy protection is implemented to enhance durability and performance.

In addition to the rigorous quality control measures implemented during the manufacturing process of the high-frequency fine Vibrating Screen and other Solids Liquid Separation Equipment, GN upholds a commitment to innovation and continuous improvement. Our research and development team consistently explores cutting-edge technologies and industry trends to enhance the performance and efficiency of our equipment. This dedication to innovation ensures that GN’s products remain at the forefront of the separation and conveying equipment industry, providing our users with access to the latest advancements.

A series of Mud cleaners and Shakers for Indonesia Project

Recently, 1 series of Desander, mud cleaner, and Shale Shaker have been manufactured and ready to start operation for an Indonesian Project.

This project marks a significant achievement in GN’s ongoing commitment to delivering top-tier solids control solutions to customers across diverse industries.

The successful sale to our Indonesian client is not only a major business milestone for GN but also reinforces our standing as a reliable provider of efficient equipment in the solids control industry. The client’s preference for our product is rooted in its proven track record of screening efficiency, durability, and low maintenance requirements.

Ensuring the reliable performance of the Desander, mud cleaner, and Shale Shaker, as well as the smooth operation of all parts and components for long-term use, has been a central focus for our technical, production, and quality control departments. Every aspect, from material selection and preparation to production steps and inspections, is meticulously attended to.

The Desander, mud cleaner, and Shale Shaker series play a pivotal role in GN’s comprehensive lineup of premium solids control and screening solutions, which includes decanter centrifuges, shale shakers, and conveyance equipment. Each product in our portfolio is crafted with cutting-edge technology, upholding the highest standards of safety and efficiency.

The successful sale of our Desander, mud cleaner, and Shale Shaker underscores GN’s commitment to delivering impactful solutions to the solids control industry, emphasizing our dedication to effectiveness and excellence.

For any assistance related to the operation and maintenance of GN’s equipment, including Desander, mud cleaner, and Shale Shaker, please feel free to contact GN company. Our team of engineers possesses extensive experience and knowledge in the industry, committed to providing the best support for the success of your project. We are also prepared to offer online support and on-site guidance tailored to address specific situations if needed, fostering stable and long-term cooperation through collaborative efforts.

GN Screw Press Unit for South American Client

News from GN company this week: Recently, a set of Sludge dewatering screw press have been manufactured and ready to start serving for Wastewater Treatment project in South American. The model number of this screw press is GNDL301, and the inlet and outlet are equipped with flanges.

In order to ensure the dependable performance of the sludge dewatering screw press and the smooth, long-term operation of all its parts and components, our technical, production, and quality control departments have dedicated meticulous attention to material selection, preparation, every stage of production, and thorough inspections at each step.

GN Separation Equipment Co., Ltd, a subsidiary of Hebei GN Solids Control Co., Ltd, specializes in the manufacturing of industrial separation equipment, including centrifuges, vibrating screens, dewatering screw presses, and pumps. With a presence in the separation industry since 2007, our manufacturing plant is located in close proximity to Beijing, China. Despite our local base, our products have achieved global reach, being exported to over 70 countries worldwide, with more than 70% tailored for international clientele.

To better serve our global customers, GN has established branches in Houston, USA, and Moscow, Russia, providing localized support. Committed to quality, our production management adheres to ISO 9001 standards, and our health, safety, and environmental systems align with ISO 14001 and ISO 28001, ensuring the delivery of high-quality products. Furthermore, GN products hold CE certificates, facilitating export to European markets.

If you need any support about the operation and maintenance of GN’s equipment like dewatering screw press and Chemical Dosing Unit, please feel free to contact GN company for our engineers’ best experience and knowledge in the relevant industry. We will do our best to assist your project because just in this way we can establish a stable and long term cooperation. And we can provide on-line support and site instruction for specific situation if needed.

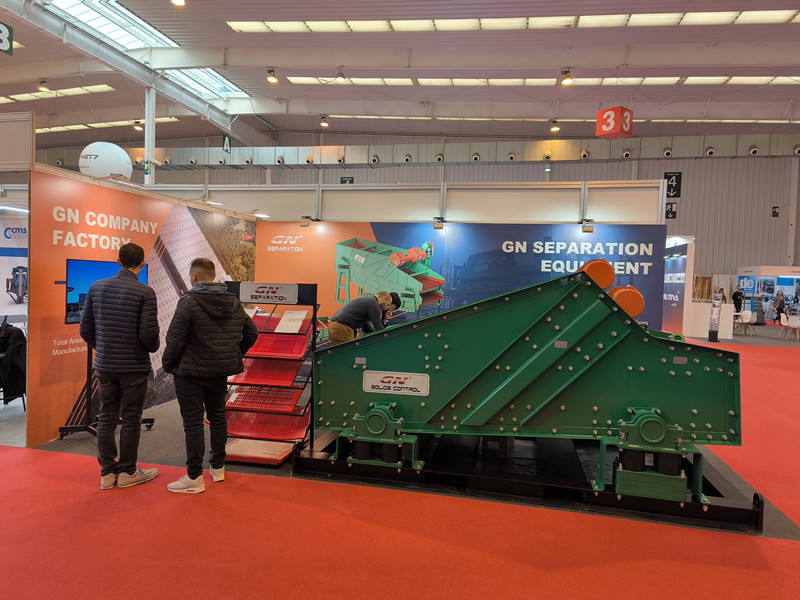

GN Separation Participated in SMOPYC Mining Exhibition

As a global frontrunner in solid-liquid separation technology, GN Separation proudly announces its active participation in the esteemed SMOPYC Mining Exhibition. This significant event, held at Feria Zaragoza, serves as a pivotal platform for industry leaders to showcase our avant-garde solutions and foster collaboration within the mining sector.

Set at Hall 3, Booth C 5-7, GN Separation is poised to unveil its cutting-edge equipment, featuring the highly acclaimed Linear Vibrating Screen GNLMP1224. This state-of-the-art screening solution, meticulously designed for optimal performance, offers unparalleled efficiency in processing materials within the mining industry. Interested visitors can explore the features and benefits of this advanced technology by visiting here.

In tandem with the Linear Vibrating Screen, GN Separation will spotlight its Polyurethane Screen Panel. Engineered with precision, these panels deliver robust performance in demanding mining applications. Visitors in search of durable and efficient screening solutions are encouraged to delve into the features of the Polyurethane Screen Panel at this link.

The SMOPYC Mining Exhibition provides a unique avenue for industry professionals to engage with GN Separation’s experts, grasp the latest advancements in separation technology, and explore how these innovations can elevate operational efficiency.

“We are thrilled to participate in the SMOPYC Mining Exhibition, a distinguished platform for industry leaders to converge and exchange ideas. GN Separation remains steadfast in delivering cutting-edge solutions that redefine industry standards,” states a spokesperson for GN Separation.

The Feria Zaragoza venue, renowned for hosting premier industry events, will bear witness to GN Separation’s unwavering commitment to excellence in solid-liquid separation technology. Industry stakeholders and visitors alike are cordially invited to firsthand experience the innovative solutions offered by GN Separation at Hall 3, Booth C 5-7.

For more comprehensive information about GN Separation and its participation in the SMOPYC Mining Exhibition, please visit the official company website: https://www.gnseparation.com.

GN Attained Fruitful Results at IMARC 2023 Mining Exhibition in Sydney

News from GN company this week: Recently, GN Separation participated in IMARC 2023 in Sydney and achieved Fruitful Results.

For more information about this show, please click below link.

https://imarcglobal.com

During this exhibition, GN Separation primarily showcased the following equipment:

Tailing Dewatering Centrifuge

GN’s Tailing dewatering decanter centrifuge is based on the T series design, it’s equipped with an 8.5-degree beach angle. The T series decanter centrifuge by GN is primarily dedicated to the processes of dewatering and thickening. Its applications are extensive, particularly in addressing the most demanding dewatering requirements within municipal and industrial wastewater sludge treatment.

This specialized dewatering decanter centrifuge is meticulously engineered for the effective separation of materials with specific characteristics, including a significant particle size, notable density contrast between solid and liquid phases, low viscosity, high concentration, substantial treatment capacity, and the achievement of a higher level of dryness compared to clarity.

In scenarios where materials, such as sludge or wastewater, contain fine particles, it is common practice to introduce flocculants to agglomerate these fine particles into larger aggregates. Subsequently, the T series decanter centrifuge is employed for dewatering, ensuring the efficient separation and removal of excess moisture.

GN’s Stack Vibrating Screen is primarily designed for the wet screening, classification, and dehydration of fine-grained materials within industries such as mineral processing and coal preparation. It offers the flexibility to be configured with 2 to 5 layers to meet on-site requirements. The GN Stack Vibrating Screen represents a proprietary product developed in-house by GN. It operates through a single vibration source (dual vibration motor), utilizing the two-degree-of-freedom resonance principle to achieve linear vibration across the entire machine.

This vibrating screen introduces a unique vibration mode, resulting in energy efficiency, high screening effectiveness, a substantial processing capacity, advanced technology, a straightforward structure, dependable and consistent operation. As a result, it stands as one of the most advanced pieces of equipment in the field of fine-grained material screening. GN Stack Vibrating Screen features Polyurethane Screen Mesh with a high opening rate (28-45%) and an average lifespan exceeding 6 months.

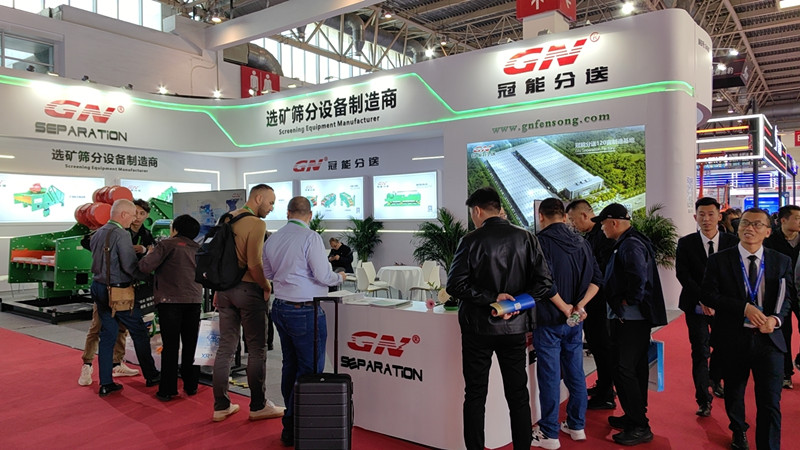

GN Separation Attains Fruitful Results at China Coal & Mining Expo 2023

Recently, GN Separation participated in the China Coal & Mining Expo 2023 and achieved Fruitful Results.

For more information about this show, please click below link.

https://www.chinaminexpo.com/hz/f?language=en_US

During this exhibition, GN Separation primarily showcased the following equipment:

1. Tailing Dewatering Centrifuge

GN’s Tailing dewatering decanter centrifuge is T series and features a beach angle of 8.5 degrees. The T series decanter centrifuge from GN is primarily employed for dewatering and thickening purposes. It finds widespread applications in meeting the most demanding dewatering needs for municipal and industrial wastewater sludge.

This dewatering decanter centrifuge is engineered for the efficient separation of materials that possess specific characteristics, such as a substantial particle size, a significant difference in density between solid and liquid phases, low viscosity, high concentration, substantial treatment capacity, and achieving a higher degree of dryness compared to clarity.

In situations where materials like sludge or wastewater contain fine particles, it is common practice to introduce flocculants to aggregate these fine particles into larger ones. Subsequently, the T series decanter centrifuge is utilized for dewatering, ensuring the separation and removal of excess moisture.

2. Linear Dewatering vbrating Screen

GN’s medium-sized linear dewatering vbrating screen features a foldable design at the screen surface’s feed end, allowing for extended material residence time and achieving rapid dewatering. This linear dewatering vibrating screen is widely employed in desliming, dewatering, media removal, and tailings dry discharge for various materials, including iron ore, non-ferrous metals, coal, and more. The screen deck wall boards are non-welded, crafted from steel plates with superior impact toughness and resistance to cold bending. Hydraulic tensioning assembly employs imported HUCK rivets, ensuring the absence of welding-induced residual stress and material defects in the wall board.

3. Solids Vacuum Pump

GN’s Solid Vacuum Pump operates entirely via external compressed air, serving as pneumatic conveying equipment. It can effectively transport materials like mud, mineral slurry, and fine aggregate with a high solid content. Its compact structure allows flexible placement at work sites, and as there are no internal moving parts, it’s easy to operate and maintain.

ATEX certified Mud Gas Separator and Vacuum Degasser to Europe Client

News from GN company this week: Recently, GN Solids Control embarked on a significant manufacturing project for a European client, producing a range of crucial equipment, including vacuum degassers and mud gas separators. These essential components have undergone rigorous certification to meet ATEX standards, ensuring the highest levels of safety and performance in the challenging environment of oil and gas drilling.

The mud gas separator plays a pivotal role in the drilling process. Its primary function is to efficiently remove large gas bubbles from the drilling mud, particularly those containing hazardous gases like H2S. This is a vital step before directing the mud to shaker screens for further processing. By effectively eliminating these gas bubbles, GN Solids Control’s vacuum degasser ensures a safer and more efficient drilling operation.

Apart from the mud gas separator, GN Solids Control offers another essential gas removal unit, available in two varieties: the vacuum degasser and the centrifugal degasser. The vacuum degasser is designed to remove fine bubbles from the drilling mud before directing it to desander or desilter cyclones. This process prevents the introduction of unwanted air into the cyclones, which can lead to rapid wear and tear. On the other hand, the centrifugal degasser provides an efficient solution while taking up less space within the drilling mud tank. This versatility allows drilling operations to choose the degassing method that best suits their specific needs and space constraints.

With a rich history in manufacturing solids control and waste management equipment, GN Solids Control has accumulated invaluable experience over the years. This expertise enables them to offer cost-effective and highly efficient solutions to oil and gas drilling contractors. GN Solids Control’s commitment to excellence and innovation has earned them a prominent position in the industry, establishing them as a trusted partner for those seeking top-tier equipment and services.

Furthermore, GN Solids Control goes beyond individual equipment components; they specialize in designing and manufacturing complete turnkey solids control systems. These systems are meticulously engineered to streamline drilling operations and enhance overall efficiency. With a comprehensive portfolio of equipment and a strong commitment to customer satisfaction, GN Solids Control stands as a reliable partner in the world of oil and gas exploration.

GN Mini Solids Control Equipment for Mining Exploration

News from GN company this week: Recently, 1 series of of GN Solids Control equipment have been manufactured and ready to start serving for an Mining Exploration project. This series of solids control equipment include:

1 set of Vibrating Screen: GNZS752J

1 set of Decanter centrifuge: GNLW223D

To ensure dependable performance from this series of Solids Control Equipment and to ensure the smooth and enduring operation of all equipment components, our technical, production, and quality control teams have meticulously focused on material selection, material preparation, every production stage, and thorough inspections at each step for this equipment suite.

If you need any support about the operation and maintenance of GN’s equipment like Vibrating Screen, mud cleaner, Decanter centrifuge, please feel free to contact GN company for our engineers’ best experience and knowledge in the relevant industry. We will do our best to assist your project because just in this way we can establish a stable and long term cooperation. And we can provide on-line support and site instruction for specific situation if needed.

GN Solids Control stands as one of the most renowned international brands in Mud Solids Control System & Drilling Waste Management. With an all-encompassing approach, GN provides a comprehensive solution for mud recycling projects.

As a preeminent manufacturer of separation and conveying equipment, GN places paramount importance on product quality and prioritizes enduring advantages for our users. It is with great pride that we present GN as an adept player in the decanter centrifuge domain. Our emphasis extends to meticulous raw material selection, utilizing high-quality centrifugal casting or forged stainless steel materials. Additionally, we employ hard alloy protection for wearing components.

By the way, if you are interested in our products, please check the following items of our company on Alibaba: