GN Separation is delighted to announce its participation in the upcoming Ecomondo Environmental Exhibition, set to take place in Rimini, Italy, this November. Ecomondo is a highly significant event within Italy, focusing on environmental and sustainable development, and it holds a prominent position in the European environmental field.

This year, Ecomondo is scheduled to run from November 7th to 10th, spanning four days. Serving as an international platform, Ecomondo offers professionals and businesses from around the world an opportunity to connect, collaborate, and access the latest insights, thereby fostering advancements in environmental protection and sustainable development.

Event Details:

Name: Ecomondo – The Green Technology Expo

Venue: Rimini Expo Centre, Italy

GN Booth: B7, 414

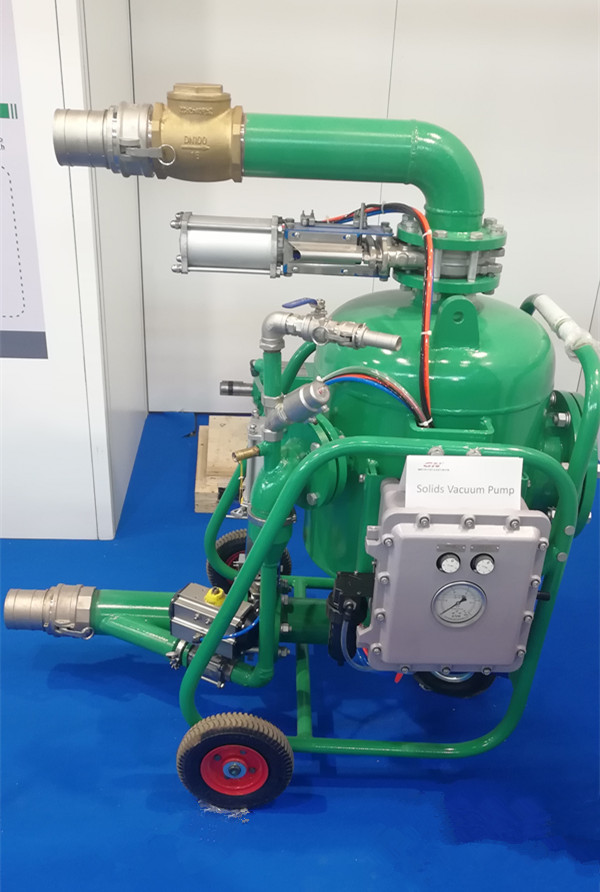

GN will showcase a range of environmental solutions, including the decanter centrifuge, solid vacuum pump, and mini screw press, each with diverse applications in the realm of environmental protection.

The sludge dewatering centrifuge is adept at fundamental separation processes such as solid-phase dewatering and liquid-phase clarification. The three-phase decanter centrifuge goes a step further by enabling liquid-liquid-solid separation. Notably, for materials like plastic particles, bacterial bodies, and oily substances, the decanter centrifuge excels due to its absence of filter media (filter screen) and the prevention of screen blockage. GN’s decanter centrifuge has proven highly effective in treating industrial wastewater, municipal wastewater, and oilfield waste oily sludge, significantly reducing treatment costs and enhancing treatment efficiency.

GN’s solid vacuum pump, a fully pneumatic device, can manage a wide spectrum of waste forms, including liquids, slurries, powders, particles, and viscous substances. It finds extensive application in municipal sludge waste treatment and industrial solid waste treatment, with its attributes of safety, efficiency, energy conservation, and environmental friendliness.

GN eagerly anticipates engaging with industry professionals and customers at the Ecomondo exhibition, introducing its products and technologies, and exploring new opportunities for collaboration. GN Separation remains committed to a customer-centric approach, driven by technological innovation, and the ongoing enhancement of product quality and service standards. Participating in the Ecomondo exhibition is viewed as a strategic move to forge connections with customers, partners, and industry experts, jointly propelling the cause of environmental protection.