GN Separation successfully manufactured four large linear dewatering vibrating screens this week, which will be deployed in domestic iron ore mines. These screens are essential for the mining industry, as efficient screening and dewatering of materials are crucial for ensuring smooth and cost-effective operations. Continue reading

Category Archives: Mining vibration screens

Stack Vibrating Screen for China Shanxi Coal Mining Company

GN Separation recently accomplished a noteworthy achievement with the successful production completion of a new batch of high-frequency stack vibrating screens, meticulously crafted for application in coal mines situated within the Shaanxi province. This development signifies a significant technological leap in the coal mining sector, as these stack vibrating screens are specifically engineered to optimize the separation of coal particles, thereby revolutionizing fine coal recovery processes while concurrently reducing waste production.

The distinguishing features of GN’s high-frequency stack vibrating screens greatly contribute to their unparalleled performance and efficiency. Foremost, the stacked design of these screens offers a myriad of advantages, notably enabling a more compact footprint. This streamlined design not only reduces the space required for installation but also facilitates seamless operation within the confines of space-constrained mining environments, which are prevalent in many coal mines across the globe.

Furthermore, GN’s vibrating screens incorporate cutting-edge technology to ensure impeccable performance and reliability. By leveraging high-quality excitation motors such as Martin or OLI motors, these screens are engineered to deliver extended periods of uninterrupted service, thereby bolstering continuous production processes while simultaneously minimizing downtime – a critical factor in maintaining operational efficiency within coal mining operations.

Moreover, the inclusion of a polyurea resin coating in the construction of these screens provides unparalleled resistance to abrasion and corrosion, thus guaranteeing sustained performance and durability even under the most demanding operating conditions. Additionally, the implementation of a unique polyurethane screen mesh further enhances the screens’ durability and flexibility, facilitating effective screening of materials and minimizing instances of blockages, thereby maximizing throughput and ultimately resulting in heightened recovery rates and superior product quality.

In addition to offering vibrating screens tailored for the mining sector, GN Separation also provides an extensive range of complementary solutions, including dewatering centrifuges designed specifically for coal slime suspension dewatering applications, thereby further enhancing its comprehensive suite of offerings for the mining industry.

For comprehensive details regarding GN Separation’s mining vibrating screens and accompanying solutions, we invite interested parties to reach out to us directly, where our team of experts stands ready to provide tailored assistance and support.

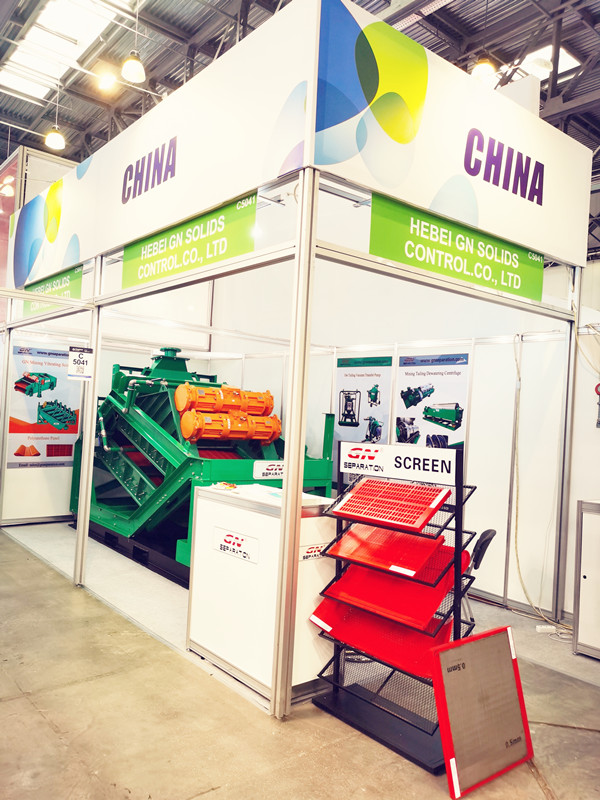

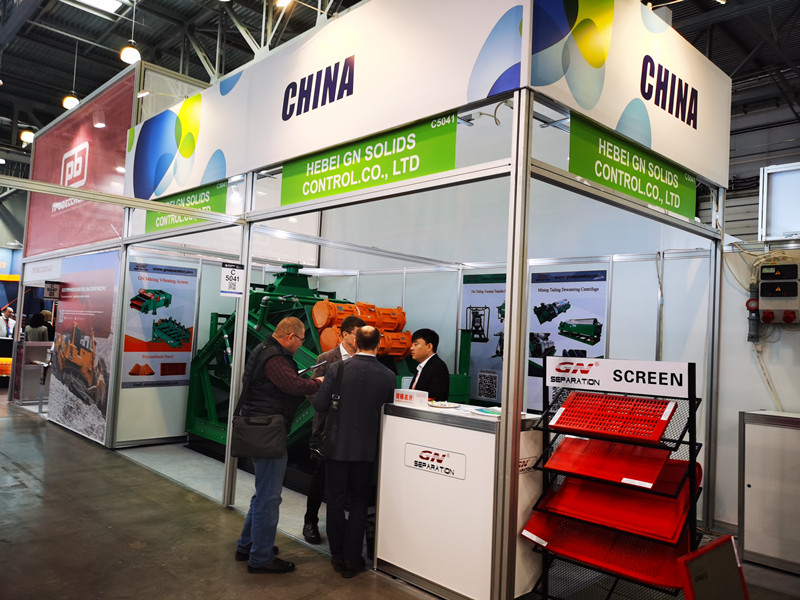

GN Separation will Attend MiningWorld Russia 2024 in April

Miningworld Russia is an international exhibition showcasing machinery and equipment for mining, processing, and transportation of minerals. GN Separation made its debut at this event in 2023 and achieved significant results. This year, GN is returning to participate, aiming to engage in business negotiations with both new and existing customers during the exhibition.

Event Name: Miningworld Russia

Event Date: April 23rd to 25th, 2024

Event Venue: Crocus Expo, Pavilion 1, Moscow, Russia GN Booth: B5001, Hall 2

As a specialized manufacturer of screening equipment for mines, GN Separation possesses extensive research and development experience along with modern intelligent technology. The company offers a range of efficient screening equipment, including linear motion dewatering vibrating screens, high-frequency stacked screens, and large banana screens. Here’s a detailed overview of the characteristics and applications of these three screening equipment types:

Medium-sized linear vibrating screen

GN’s linear vibrating screen boasts excellent design and stable performance. It finds wide applications in desliming, dewatering, media removal, and tailings dry discharge treatment across materials such as iron ore, non-ferrous metal ore, and coal mines. Notable advantages include efficient dewatering, a robust structure, wear resistance, corrosion resistance, and flexible customization options.

High-frequency stack vibrating screen

GN’s high-frequency stack vibrating screen is popular for its stacked design and efficient screening efficiency. Its surface is coated with polyurea resin for enhanced wear and corrosion resistance. The stack-layered design optimizes material collection, reduces floor space, and enhances space utilization. Additionally, high-frequency vibration effectively prevents sieve hole blockage, thereby improving screening efficiency.

GN’s large banana vibrating screen is primarily used for dry or wet classification, desliming, and media removal processes. Key features include forced synchronization, efficient classification, and strong adaptability.

In summary, each type of GN vibrating screen offers unique characteristics to meet diverse screening needs in different mining applications. GN looks forward to meeting you at the exhibition.

8 SETS GN LINEAR DEWATERING VIBRATING SCREEN PRODUCED READY FOR DOMESTIC IRON MINE

Recently, GN Separation announced the successful completion of a batch of 8 units of linear motion dewatering screens for iron ore, which underwent trial runs at GN Separation factory. These dewatering screens are ready to be shipped to domestic customers to provide powerful technical support for the iron ore screening process on-site.

Iron ore screening, as a main step in the entire processing flow, has a direct impact on the final quality of the iron ore. GN’s linear dewatering screens, with their efficient and stable performance, have become a valuable asset in the iron ore screening process. They effectively removes liquid media from iron ore, ensuring its efficiency and quality during subsequent processing.

The popularity of GN’s linear dewatering screens can be attributed to their unique design and advanced technology. Among them, the Huck bolt connection for the screen deck wall plate not only avoids potential stress issues associated with traditional welding methods but also enhances the stability and durability of the equipment. The adoption of the renowned OLI brand vibration motor ensures efficient and stable operation, while also reducing maintenance costs for users. The polyurethane screen panel, known for its excellent wear resistance and corrosion resistance, significantly extends the service life of the equipment and improves screening efficiency.

Furthermore, the modular installation design allows for flexible adjustment of the screen panel’s position, facilitating both on-site installation and faster screen panel replacement. This significantly reduces equipment downtime. The large screening area design enables the equipment to perform dewatering operations quickly and efficiently, further enhancing the processing efficiency of iron ore.

In addition to linear dewatering screens, GN Separation also offers a range of other mining vibration screens, such as high-frequency fine screens, banana screens, and flip-flow screens, stack vibrating screen, double deck linear vibrating screen. These products are widely used in the screening of iron ore, coal, and non-ferrous metal mines, providing customers with comprehensive and efficient screening solutions.

As a leading manufacturer of mining screening equipment, GN Separation has always focused on developing and producing efficient and stable mining screening equipment while putting customers at the center. In the future, GN will continue to dedicate itself to technological innovation and product upgrades, making even greater contributions to the global mining industry. We look forward to GN continuing to lead the technical trend of mining screening equipment, providing the global mining industry with more efficient, stable, and reliable solutions.

Linear Dewatering Vibrating Screens Ready for A Domestic Mining Project

This week GN proudly announced the completion of a series of Linear Dewatering vibrating screens (model number GNLMZ1848, 8 sets in total), specially crafted to serve a Domestic Iron Mine Project. This achievement underscores our unwavering commitment to delivering cutting-edge solutions tailored to meet the unique needs of our valued clients. Our Dewatering vibrating screens stand at the forefront of innovation, finding extensive application across diverse industries including mining, coal, construction, metallurgy, and chemicals.

What sets GN’s Dewatering vibrating screens apart is the utilization of advanced design techniques such as finite element analysis and anti-fatigue analysis. This meticulous approach ensures a rational structure, low energy consumption, and impressive dewatering and dry discharge capacities, all while adapting seamlessly to corrosive and abrasive working conditions. With its large processing capacity, high efficiency, and steadfast performance, our vibrating screen offers unparalleled reliability and productivity.

Customization options are available to cater to specific customer requirements, ensuring seamless integration into various operational environments. Whether it’s dewatering, desliming, demineralization, or dry discharge of mining tailings, GN’s Linear Dewatering Vibrating Screen delivers optimal results.

To uphold our commitment to quality and reliability, our technical, production, and quality control departments have spared no effort in meticulously overseeing material selection, preparation, production processes, and inspection protocols at every step of the manufacturing process. This ensures that each unit meets our stringent standards for performance, durability, and longevity.

Furthermore, should you require assistance with the operation and maintenance of Construction Mud Solids Liquid Separation Equipment, including our mining vibrating screens such as Medium-sized Linear Dewatering Screens and High-frequency Linear Screens, as well as Decanter Centrifuges, our team of seasoned engineers is readily available to provide comprehensive support. We prioritize the success of your projects and are committed to fostering enduring partnerships by offering tailored solutions and exemplary customer service.

At GN, we take immense pride in our role as a leading manufacturer of separation and conveying equipment. Our dedication to innovation, quality, and customer satisfaction remains unwavering as we continue to push the boundaries of excellence in the industry. Contact us today to experience the GN difference firsthand and discover how our solutions can elevate your operations to new heights of success.