GN Separation would like to invite all of our clients and friends to join ASIA WATER 2024 Exhibition In April held In Malaysia.

Expo. Website https://www.asiawater.org

Expo. Name: ASIA WATER 2024

Add.: Kuala Lumpur Convention Centre

GN Booth No.: Hall 6, B602

Expo Time: April 23-25th, 2024

ASIAWATER 2024, the region’s leading water & wastewater platform for developing Asia, will return at the heart of modern Malaysia’s city centre, the Kuala Lumpur Convention Centre, from the 23 – 25 April 2024, with the central theme “Water and Climate Change: Innovation for Resilience”.

During this exhibition, GN will show the following equipment:

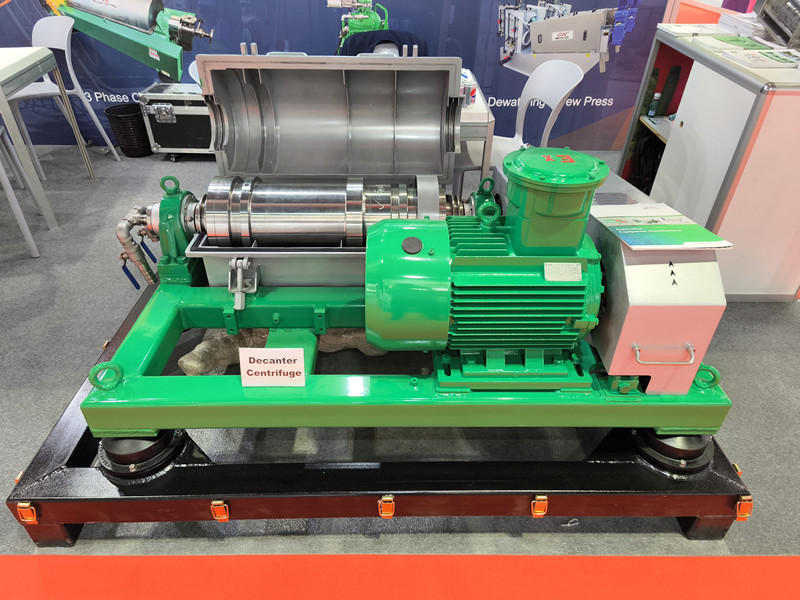

Decanter centrifuge is a widely used equipment in the field of industrial solid-liquid separation. According to the characteristics of different materials in different industries, GN decanter centrifuge is divided into dewatering, separation, and clarifying decanter centrifuge. With centripetal pump technology, GN decanter centrifuge can also realize the 3-phase separation of liquid, liquid, and solids. GN will bring 2-phase decanter centrifuge GNLW223 to the exhibition.

If you are having a headache when moving high viscosity drilling cuttings, then GN Solids Vacuum Pump is the best choice. GN has built 3 different models: GNSP-10B, GNSP-20B and GNSP-40B. We will show GNSP-10B at the exhibition.

Sludge dewatering screw press

GN screw press sludge dewatering machine is a kind of economic and environmental friendly sludge dewatering equipment. It is a new type of sludge extrusion dewatering equipment by using the principle of screw extrusion, through the strong squeezing force generated by the change of screw diameter and screw pitch, and the tiny gap between the floating ring and the fixed ring, to realize solid-liquid separation.

All of the clients of GN are welcome to visit the ASIA WATER 2024 EXHIBITION. We hope we will have a fruitful meeting and a happy Cooper with you. If you need any support about the operation and maintenance of GN’s equipment, please feel free to contact GN company for our engineers’ best experience and knowledge in the relevant industry. We will do our best to assist your project because just in this way we can establish a stable and long term cooperation. And we can provide on-line support and site instruction for specific situation if needed.