GN Separation has successfully completed the assembly and shipment of a significant batch of sludge transfer pumps for international clients. Featuring two advanced technologies – the screw pump and the solid Vacuum Pump – this range underscores GN Separation’s expertise in designing efficient and dependable equipment for sludge management and material handling. Continue reading

Category Archives: Vacuum pump

GN Will Attend IFAT MUNICH THIS MAY

IFAT MUNICH 2024, recognized as the premier global platform for environmental technology exhibitions, continues its legacy as the foremost trade fair for water, sewage, waste, and raw materials management Continue reading

GN SEPARATION SCORES BIG AT AISAWATER 2024 MALAYSIA WATER EXHIBITION

GN Separation has emerged triumphant from the recently concluded Aisawater 2024 exhibition in Malaysia, marking a significant milestone in its journey of innovation and global expansion. Continue reading

GN Solid Vacuum Pump Inventory Meets Customer Fast Delivery Demand

GN Separation has recently announced a significant update regarding its inventory of Solid Vacuum Pumps, including models GNSP10B, GNSP20B, and GNSP40B. This strategic stock enhancement is poised to meet the rapidly growing demand for fast deliveries among its clientele, ensuring that businesses can maintain uninterrupted operations.

We are excited to announce a significant update regarding our inventory of Solid Vacuum Pumps at GN Separation, particularly models GNSP10B, GNSP20B, and GNSP40B. This strategic enhancement of our stock is aimed at meeting the increasing demand for fast deliveries among our clientele, ensuring uninterrupted operations for businesses.

GN Separation‘s Solid Vacuum Pumps are designed to cater to a wide range of industrial applications, including environmental protection, mining, and wastewater treatment. Our latest models, GNSP10B, GNSP20B, and GNSP40B, are tailored to different operational scales, offering solutions for businesses of any size. For instance, the GNSP10B model is ideal for smaller-scale operations requiring mobility and efficiency, while the GNSP40B model is suitable for larger, more demanding projects that involve substantial volumes of solid waste or materials.

The decision to bolster our inventory levels is a response to the industry’s demand for reliable and swift delivery of critical equipment. With these models readily available, GN Separation reaffirms its commitment to supporting our customers’ operational needs promptly. This readiness not only showcases our understanding of market demands but also underscores our dedication to providing high-quality solutions without delay.

Furthermore, our Solid Vacuum Pumps are renowned for their robust design, energy efficiency, and ease of operation, contributing to lower operational costs and a more environmentally friendly footprint. These features align with the industry’s push towards sustainable practices.

Customers interested in GN Separation’s Solid Vacuum Pumps can now expect faster delivery times, thanks to our proactive approach to inventory management. This development is particularly beneficial for businesses aiming to minimize downtime and expedite project completion.

We believe that this announcement will be well-received by the industry, reflecting GN Separation’s ongoing commitment to customer satisfaction and our ability to anticipate and meet market needs efficiently.

For more information on GN Separation’s Solid Vacuum Pumps, including detailed product specifications and applications, please visit our website.

GN Separation Actively Invests in Inventory to Satisfy Fast Delivery of Solid Vacuum Pump Orders

GN Separation recently announced that in order to demonstrate its strong financial strength and confidence in its products, the company has decided to proactively invest in storing solid vacuum pump inventory to ensure rapid response to market demand and meet customers’ fast delivery requirements.

This proactive inventory strategy not only reflects GN Separation’s emphasis on business continuity and efficiency, but also highlights the company’s commitment to customer satisfaction. GN Separation is well aware that in the fiercely competitive market environment, rapid response and efficient delivery are the keys to winning customer trust and maintaining competitiveness.

It is worth mentioning that GN Separation’s solid vacuum pumps have received widespread praise in the market for their exceptional functionality and reliability. As a fully pneumatic device, it can easily handle various materials, including liquids, slurries, solid powders, and particles, providing ideal solutions for various industries.

In addition, GN Separation’s solid vacuum pumps feature an automatic operation mode that allows operators to flexibly adjust the suction and discharge time based on the specific characteristics of the processed materials and the requirements of the working environment, thereby optimizing performance. This innovative design not only improves the usability of the pump but also brings greater convenience and benefits to customers.

GN solid vacuum pump has the following features:

a. The equipment operates using 100% pneumatic power, with no power requirements, allowing safe operation in hazardous areas and ensuring explosion-proof safety;

b. There are no rotating parts inside the equipment tank, reducing the risk of danger, blocked and maintenance cost;

c. It uses negative pressure (vacuum) for material suction, generating a vacuum of up to 25″HG (equivalent to an 8-meter water column vacuum), resulting in superior suction performance;

d. The equipment is easy to operate and can be operated by a single person;

e. The equipment has compact structure, convenient lifting and easy movement;

f. The equipment can achieve automatic suction and discharge of materials.

By investing in pre-purchase and storage of solid vacuum pumps, GN Separation is not only preparing to meet market demand but also demonstrating the company’s commitment to innovation and quality. We believe that as solid vacuum pumps are widely used in various industries, GN Separation’s investment in inventory will yield substantial returns.

Here, we encourage customers seeking reliable and efficient vacuum pump solutions to contact GN Separation as soon as possible and place advance orders to ensure timely delivery and avoid potential delays. We will provide you with quality products and services and work together to create a bright future.

GN Solid Vacuum Pump for Overseas Polypropylene Slurry Conveying

News from GN Separation: Recently, a set of Solid Vacuum Pump (Model GNSP20B) with transfer hoses have been manufactured and ready to start serving a Polypropylene Slurry Conveying project.

GN Solids Vacuum Pumps are extensively utilized across various industries and applications, including:

Thickener de-sludging

Tunneling and TBM (Tunnel Boring Machine) applications

Sump and shaft cleaning

Tailings and ash pond cleaning

Digester and pond cleaning

Oil spill capture and transfer

Cleanup of under-belt spillage

Hazardous waste recovery

Drilling mud and cuttings transfer

Transfer of mining slurries

Offal transfer

High-volume guck and slimes transfer

With their versatility and efficiency, GN Solids Vacuum Pumps offer reliable solutions for a wide range of solids and sludge transfer applications in various industries.

To ensure the Solid Vacuum Pump will deliver reliable performance and all the components will run smoothly for long-term operation, our technical, production, and quality control departments have meticulously focused on material selection, preparation, every production step, and thorough inspections at each stage.

If you need support regarding the operation and maintenance of the Vacuum Pump, feel free to contact GN company for our engineers’ best experience and knowledge in the relevant industry. We are committed to assisting your project to establish stable and long-term cooperation. We also offer online support and on-site instruction for specific situations if needed.

As a leading manufacturer of separation and conveying equipment,GN Separation prioritizes product quality and considers the long-term benefits for our users. In the decanter centrifuge field, GN is a professional manufacturer, giving careful attention to raw material selection. High-quality centrifugal casting or forging stainless steel materials are used, and for wearing parts, hard alloy protection is applied.

GN utilizes advanced CNC lathes, CNC centers, and CNC gantry milling machines to guarantee the precision of centrifuge parts machining. In terms of dynamic balance, GN employs a comprehensive approach that includes not only standard low and medium-speed dynamic balance but also a high-speed dynamic balance process. This meticulous process dynamically balances the centrifuge screw and bowl at operational speeds, ensuring optimal performance. GN’s decanter centrifuges are widely utilized across diverse industries and are exported to more than 60 countries and regions worldwide, garnering acclaim from satisfied customers.

Solid Vacuum Pump: A Valuable Assistant in Polymer Slurry Transferring

In today’s industrial field, efficient and safe material transportation is pivotal in enhancing production efficiency and reducing costs. This week, GN Separation is excited to share that we have successfully completed the production and factory test of a set of GNSP-20B solid vacuum pump and promptly delivered it to our European customer’s site. The primary task of this pump is to assist in the efficient transportation of polymer slurry.

The solid vacuum pump is the core equipment in our soly developed material transportation system, operating based on vacuum suction technology. It offers unique advantages compared to other similar products. Firstly, it is 100% air-driven, eliminating the need for power connections, and features a compact design. This ensures stable operation under various environmental conditions, meeting the transferring requirements of various highly fluid or loose materials such as liquids, slurries, and solid powders.

Working principle:

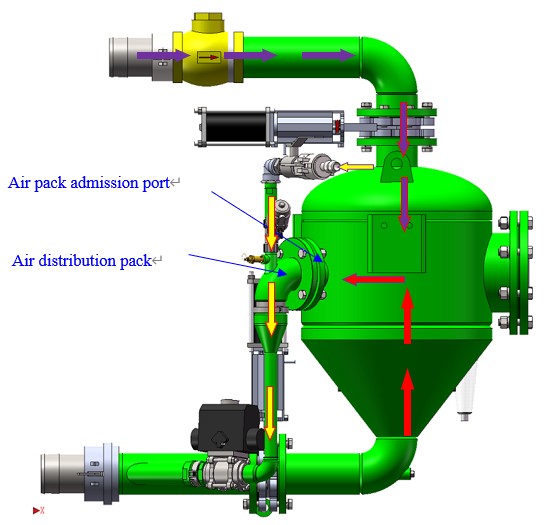

Material Suction: High pressure and high-speed air get into the jet air tube assembly via inlet (high vacuum is produced by the air pocket in the jet air tube assembly) producing high vacuum in the tank for material suction.

1)Yellow arrows indicate compressed air flow direction; Red arrows indicate air flow direction inside the tank; Purple arrows indicate material entering direction;

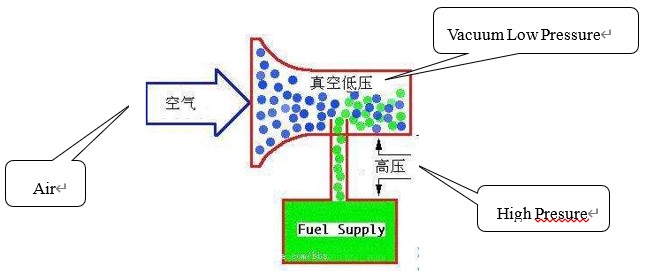

2)Air enters into the distribution pocket via inlet, vacuum produced in the air distribution pocket. (when restricted flow passes the contractible cross section, flow speed will increase. Flow speed is inversely proportional to the cross section, the increasing of speed will go with reducing of fluid pressure. Low pressure will be produced near high speed fluids, then produce suction action);

3)When low pressure produced at the air pocket, the air in the tank flows towards the air pocket and gets out together with compressed air, and then vacuum generated in the tank;

4)When pressure inner tank is lower than ambient pressure, material will gets into the tank under atmospheric pressure.(6-8 meters suction height of water, suction height is different due to material density and viscosity differences ).

Principle Diagram:

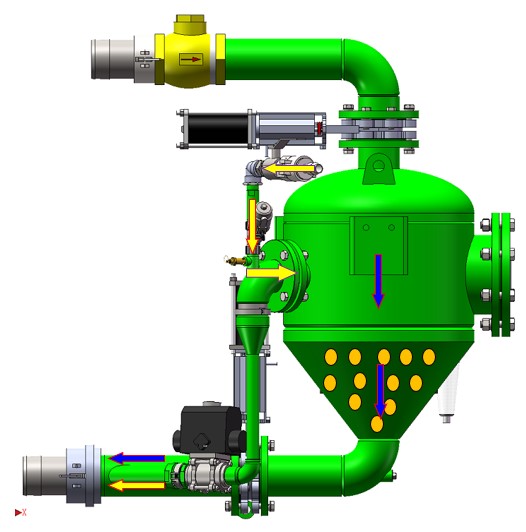

Discharge Material:

1) After suction process, compressed air flow direction changes and gets into the material storage tank, as above picture showing. Pressure inside tank will be higher and higher, finally the material is discharged out under high pressure and flows faraway with compressed air.(Max. horizontal transferring distance reaches 500-1000 meters, actually distance is different due to different material density and viscosity);

As an efficient and environmentally friendly transportation device, the solid vacuum pump plays a significant role in polymer slurry transportation. This pump can effortlessly handle the challenges of transporting highly fluid or loose materials, ensuring smooth production processes. Furthermore, due to its compact structure and simple operation, the solid vacuum pump not only reduces operational costs but also improves production efficiency.

Beyond its application in polymer slurry transportation, the solid vacuum pump has widespread applications in many other industries. For instance, in the oil and gas industry, it can be used for the transportation of drilling cuttings and oily sludge. These materials often exhibit high specific weights and high solid phase content, making the solid vacuum pump an ideal choice for handling them.

It’s worth mentioning that the GN solid vacuum pump has obtained EU CE and ATEX certifications, fully compliant with the stringent standards of the European market. This means that our products not only feature excellent performance but also possess a high level of safety and reliability. For customers who require high-efficiency and high-safety material transportation solutions, the GN solid vacuum pump is undoubtedly a trusted option.

Looking ahead, we believe that the solid vacuum pump will continue to play a significant role in polymer slurry and other material transportation. With ongoing technological advancements and growing market demands, we will remain committed to developing more efficient and safer material transportation solutions to meet the needs of our global customers.

If you are interested in our solid vacuum pumps or would like to learn more information, please feel free to contact us. We look forward to creating a brighter future together!

GN Solid Vacuum Pump for Garnet Powder Transportation in Middle East

News from GN Separation: Recently, a set of Solid Vacuum Pump with transfer hoses have been manufactured and ready to start serving a Garnet Powder Transportation project in Middle East.

To ensure the Solid Vacuum Pump along with hoses, delivers reliable performance and all components run smoothly for long-term operation, our technical, production, and quality control departments have meticulously focused on material selection, preparation, every production step, and thorough inspections at each stage.

If you need support regarding the operation and maintenance of the Vacuum Pump, feel free to contact GN company for our engineers’ best experience and knowledge in the relevant industry. We are committed to assisting your project to establish stable and long-term cooperation. We also offer online support and on-site instruction for specific situations if needed.

As a leading manufacturer of separation and conveying equipment,GN Separation prioritizes product quality and considers the long-term benefits for our users. In the decanter centrifuge field, GN is a professional manufacturer, giving careful attention to raw material selection. High-quality centrifugal casting or forging stainless steel materials are used, and for wearing parts, hard alloy protection is applied.

GN utilizes high-end CNC lathes, CNC centers, and CNC gantry milling machines to ensure the machining accuracy of centrifuge parts. In terms of dynamic balance, GN employs not only ordinary low and medium-speed dynamic balance but also a high-speed dynamic balance process. This process dynamically balances the centrifuge screw and bowl at the actual working speed. GN’s decanter centrifuges find wide applications in various industries and are exported to over 60 countries and regions worldwide, earning high praise from customers.