In today’s industrial field, efficient and safe material transportation is pivotal in enhancing production efficiency and reducing costs. This week, GN Separation is excited to share that we have successfully completed the production and factory test of a set of GNSP-20B solid vacuum pump and promptly delivered it to our European customer’s site. The primary task of this pump is to assist in the efficient transportation of polymer slurry.

The solid vacuum pump is the core equipment in our soly developed material transportation system, operating based on vacuum suction technology. It offers unique advantages compared to other similar products. Firstly, it is 100% air-driven, eliminating the need for power connections, and features a compact design. This ensures stable operation under various environmental conditions, meeting the transferring requirements of various highly fluid or loose materials such as liquids, slurries, and solid powders.

Working principle:

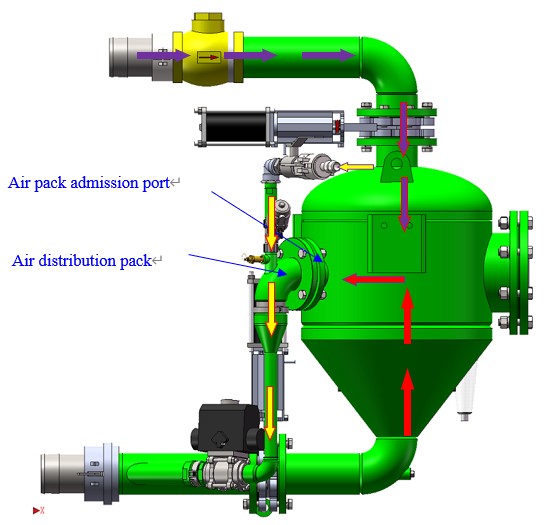

Material Suction: High pressure and high-speed air get into the jet air tube assembly via inlet (high vacuum is produced by the air pocket in the jet air tube assembly) producing high vacuum in the tank for material suction.

1)Yellow arrows indicate compressed air flow direction; Red arrows indicate air flow direction inside the tank; Purple arrows indicate material entering direction;

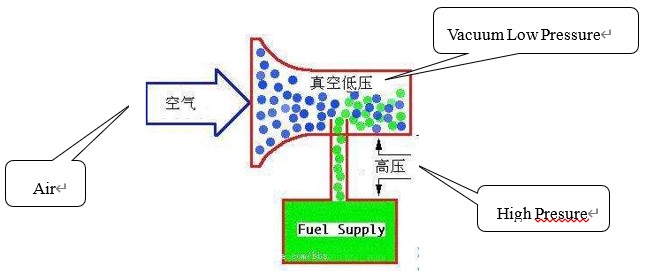

2)Air enters into the distribution pocket via inlet, vacuum produced in the air distribution pocket. (when restricted flow passes the contractible cross section, flow speed will increase. Flow speed is inversely proportional to the cross section, the increasing of speed will go with reducing of fluid pressure. Low pressure will be produced near high speed fluids, then produce suction action);

3)When low pressure produced at the air pocket, the air in the tank flows towards the air pocket and gets out together with compressed air, and then vacuum generated in the tank;

4)When pressure inner tank is lower than ambient pressure, material will gets into the tank under atmospheric pressure.(6-8 meters suction height of water, suction height is different due to material density and viscosity differences ).

Principle Diagram:

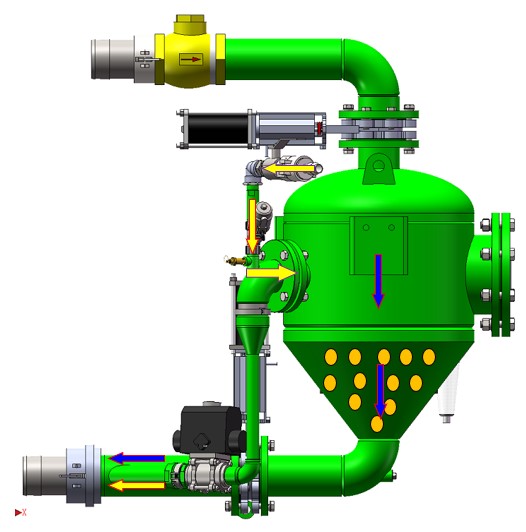

Discharge Material:

1) After suction process, compressed air flow direction changes and gets into the material storage tank, as above picture showing. Pressure inside tank will be higher and higher, finally the material is discharged out under high pressure and flows faraway with compressed air.(Max. horizontal transferring distance reaches 500-1000 meters, actually distance is different due to different material density and viscosity);

As an efficient and environmentally friendly transportation device, the solid vacuum pump plays a significant role in polymer slurry transportation. This pump can effortlessly handle the challenges of transporting highly fluid or loose materials, ensuring smooth production processes. Furthermore, due to its compact structure and simple operation, the solid vacuum pump not only reduces operational costs but also improves production efficiency.

Beyond its application in polymer slurry transportation, the solid vacuum pump has widespread applications in many other industries. For instance, in the oil and gas industry, it can be used for the transportation of drilling cuttings and oily sludge. These materials often exhibit high specific weights and high solid phase content, making the solid vacuum pump an ideal choice for handling them.

It’s worth mentioning that the GN solid vacuum pump has obtained EU CE and ATEX certifications, fully compliant with the stringent standards of the European market. This means that our products not only feature excellent performance but also possess a high level of safety and reliability. For customers who require high-efficiency and high-safety material transportation solutions, the GN solid vacuum pump is undoubtedly a trusted option.

Looking ahead, we believe that the solid vacuum pump will continue to play a significant role in polymer slurry and other material transportation. With ongoing technological advancements and growing market demands, we will remain committed to developing more efficient and safer material transportation solutions to meet the needs of our global customers.

If you are interested in our solid vacuum pumps or would like to learn more information, please feel free to contact us. We look forward to creating a brighter future together!