The complete set of sludge dewatering treatment is an important equipment in urban domestic sewage treatment, sludge treatment in the process of tap water production, and industrial and agricultural sewage treatment projects. It has the integrated processing functions of sludge dewatering and sludge concentration and dewatering. A fully enclosed continuous running large-aspect-ratio Decanter centrifuge is generally used as the main body of sludge dewatering. It has more advantages than other types of sludge dewatering equipment :

1. Fully enclosed operation, clean and pollution-free on site;

2. The amount of flocculant and cleaning water is small, and the daily running cost is low;

3. The equipment layout is compact and the area is small, which can significantly reduce land acquisition and infrastructure investment.

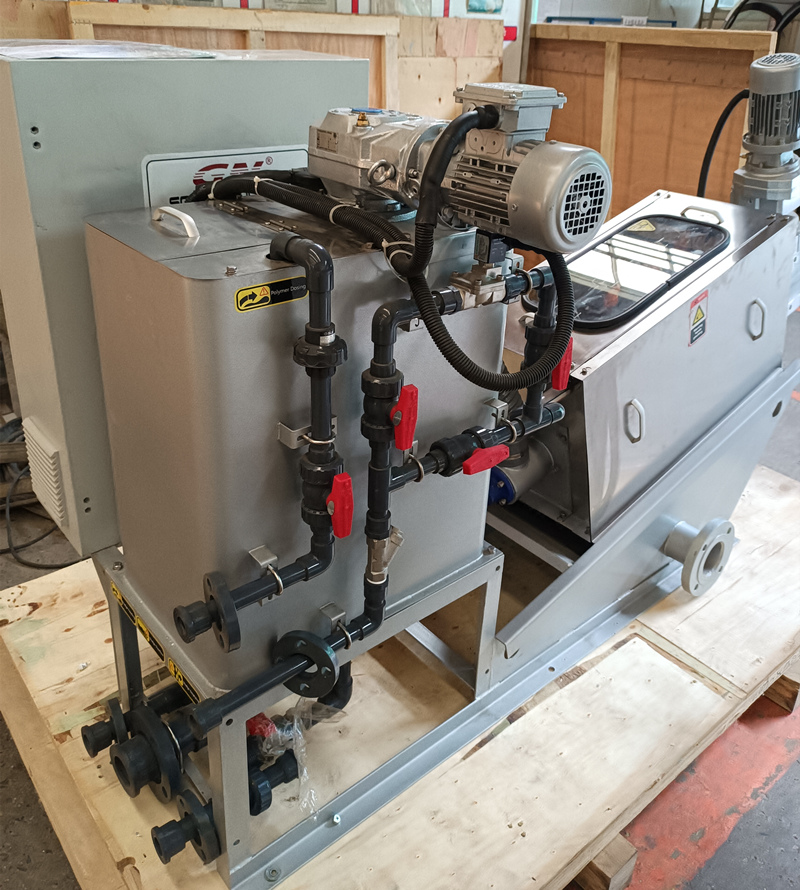

The sludge centrifugal dewatering Decanter centrifuge manufactured by GN company has a large length-to-diameter ratio and high speed. It is also equipped with pumps and conveyors to feed and discharges sludge, and conveys the sludge during the entire processing process, and with dosing unit to add flocculant to the entire system The monitoring of operating conditions is implemented by the control system of PLC + LCD screen. For users, this device is an ideal turn-key project as a fully automated complete operating unit.

1. Sludge feeding system: composed of sludge feed pump, electromagnetic flow meter, valve, pipeline, etc .;

2. Flocculant dosing system: It is composed of PT dry powder automatic quantitative dosing device, dilution water device, dosing screw pump, valve, pipeline, etc. It can realize fully automatic feeding, dissolving, aging, storage, dosing and other processes. The whole process runs completely automatically without human operation.

3. Proportioning system of specific gravity agent: mixing tank, electric diaphragm pump, valve, pipeline, etc. The system is a supporting device for dewatering of oily sludge.

4. Dewatering sludge conveying system (screw conveyor): The design of the screw conveyor can effectively prevent the clogging and entanglement of mud cakes, and is widely used in the transportation of sludge after centrifugal dewatering of sludge.

5. Electronic control system (PLC + LCD screen full automatic control, dynamic picture display): It consists of decanter main engine, feed pump, dosing pump, dilution water pump, PLC control and related electrical components control box and LCD touch screen.