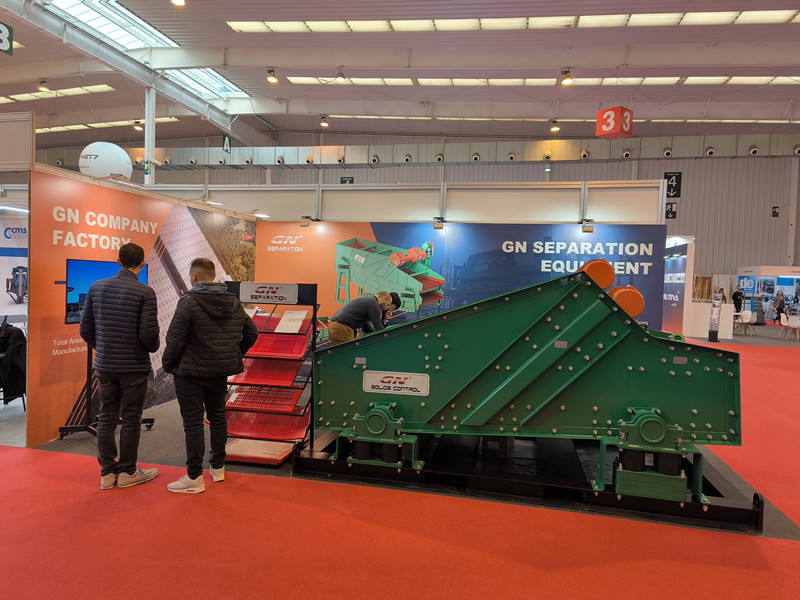

Several days ago, GN Separation has successfully assembled and undergone factory testing for a high shear circular vibrating screen, model no. GNYK1028, which is scheduled to be shipped abroad for a silica sand classification project.

GN High Shear Circular Vibration Screen is a groundbreaking equipment, developed solely by GN Separation Technical Team. This innovative screening equipment is designed to harness the power of a single vibration source, a vibration motor, to generate circular motion in the screen deck assembly. Its working principle is to sieve the materials on the screen driven by the vibrator. The technology design makes it of excellent performance on processing a range of materials, including but not limited to the following categories:

Chemical products: such as pigments, coatings, paints, resins, titanium dioxide powder, rubber particles, etc.

Food: such as flour, sugar, salt, grains, etc.

Medicine: such as Chinese herbal medicine, western medicine, bulk drugs, etc.

Ceramics and mining: such as ores, like iron ore, gold ore, silica sand, feldspar, coal, etc.

My pleasure to introduce its outstanding features as below:

- Robust Operation: The screen relies on high-performance vibration motor brands like Martin motor or OLI motor, ensuring it with both dependable operation and long trouble-free operation time.

- Efficient Processing: The screen deck is meticulously designed with multiple sections, significantly boosting its treatment capacity. This configuration offers higher working efficiency, lower energy consumption, consistent performance, and reduced customers’ maintenance needs in actual applications.

- Enhanced Screening Effect: Each section of the mesh is equipped with a re-pulp spray pipeline, which further improving the screening process efficiency.

- Durable Construction: Heat treatment technical carried out on the whole screen deck ensure it to withstand the high-intensity vibration during long-term using. Via surface heat treatment, the screen mesh surface structure is changed to more compact and stronger, improving hardness and corrosion resistance, thereby enhancing its wear resistance and durability. Meanwhile, form a protective film cover, which can effectively prevent the screen mesh from being oxidized and corroded to enhance the corrosion resistance of the screen mesh and extend its service life. What’smore reduce the roughness of the screen mesh surface, making it smoother, effectively improve the working performance of the screen mesh and increase its screening efficiency and accuracy.

- Quiet Operation: The use of flexible polyurethane screen mesh, ensures minimal equipment noise in operation. It is a kind of high molecular polyurethane elastomer, with excellent physical and mechanical properties: high strength, large elasticity and rather nice wear resistance, with an opening rate of polyurethane screen mesh is 28% ~ 45%. GN is committed to providing customers with flexible polyurethane screen mesh with finer mesh, higher opening area and better polyurethane screen surface.

- Easy Maintenance: The screen mesh is secured using bolt components that are easy to disassemble for inspection and reassembly, ensuring convenient and reliable fastening.

- Longevity: The vibrating screen components’ fluids touching surfaces are coated with a polyurethane resin wear-resistant and anti-corrosion layer or protected by wear-resistant rubber plates by the spraying machine imported from the United States, which is corrosion-resistant, erosion resistant and wear-resistant. Which extends the durability of the screen equipment.

As a high-frequency vibrating screen, GN High Shear Circular Vibration Screen operates at a frequency of 25Hz, ensuring efficient separation of materials even at smaller sizes. It can be applied in various working conditions that are easy to corrode and wear. Large processing capacity, high efficiency and stable performance. GN manufactures proffessional Mining Vibrating Screen, including Stack Vibrating Screen, High Frequency Vibrating Screen, Dewatering Vibrating Screen, Classification Vibrating Screen, Large Mining Vibrating Screen. Welcome to contact GN now.