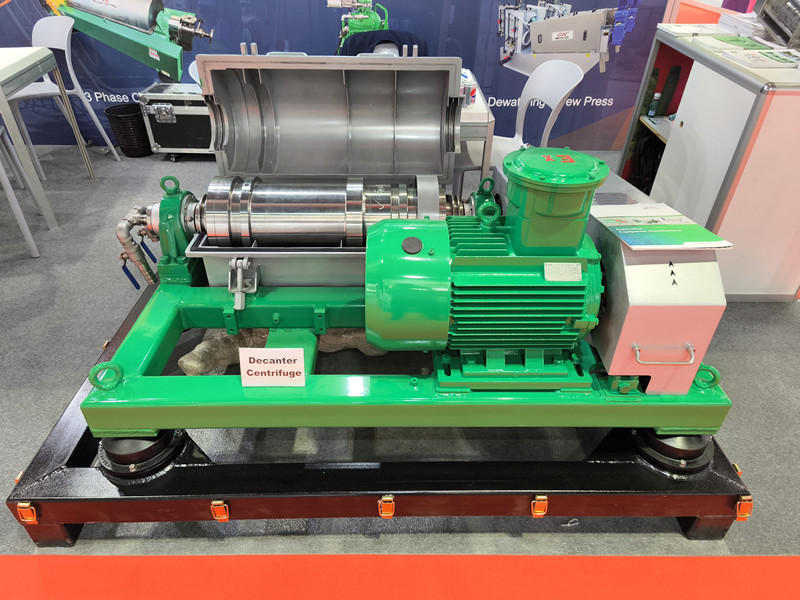

After the no-load test run of decanter centrifuge is qualified, the load test can be carried out according to the operating regulations, and the load test time is not less than 8h.

- Start-up sequence

Speed control potentiometer reset to zero position (if not reset to zero, the potentiometer is interlocked with the main motor control switch, the motor cannot start) Close the power brake, press the start button, the asynchronous motor starts, and observe whether the stabilizer oil mark comes Turn on the power switch of the speed controller, slowly turn the speed potentiometer knob to start the decanter centrifuge, increase the speed from 0 to the working speed of no less than 2min Press the work button, the overload protection circuit is put into operation, and the motor appears Current indication. The empty vehicle current is less than 18A when not feeding.

- Feeding operation

Feeding sequence: After the empty car runs at normal speed, it is rinsed with clean water for 5 minutes, and then fed to the continuous production. For example, after stopping the feed, rinse with clean water for 10 minutes, and then stop the host. The feeding speed should be strictly controlled. It is one of the important factors that determine the solid content of the filtrate and the moisture content of the slag. The motor current during feeding is the empty vehicle current plus 5~6A. There should be no leakage at the seals. After the operation, measure the temperature of the two main bearings. The temperature of the main bearing of the feed end is allowed to be +25 degrees of the feed temperature, the temperature of the main bearing of the other end is 65 degrees, and the temperature of the differential case is 70 degrees (both measured at the position of the case). Measure the vibration and vibration at the two main bearing seats. The strength is not more than 11.2mm/s. Measure whether the production capacity meets the requirements and carefully make test drive records.

Check before decommissioning of decanter centrifuge:

- Check the tightening of all bolts for looseness, breakage, shortage, etc.

- Check whether the electric steering is correct, the belt tension is appropriate, and the pulley is intact

- Check whether the oil level of the bearing housing meets the requirements

- Rotate the drum with the hand wheel, it should be easy and flexible without rubbing.