News from GN company this week: Recently, 1 series of Double Deck Linear Motion Shale Shakers have been manufactured and ready to start serving a new project for an European Client.

To make sure the Double Deck Linear Motion Shale Shakers will provide a reliable performance and the parts and components of all the equipment will run smoothly for a long term operation, our technical department, production department and quality control department have paid a lot of attention to the material selection, material preparation, every step of production and the inspection for the Double Deck Linear Motion Shale Shaker in each step.

If you need any support about the operation and maintenance of the Double Deck Linear Motion Shale Shaker , please feel free to contact GN company for our engineers’ best experience and knowledge in the relevant industry. We will do our best to assist your project because just in this way we can establish a stable and long term cooperation. And we can provide on-line support and site instruction for specific situation if needed.

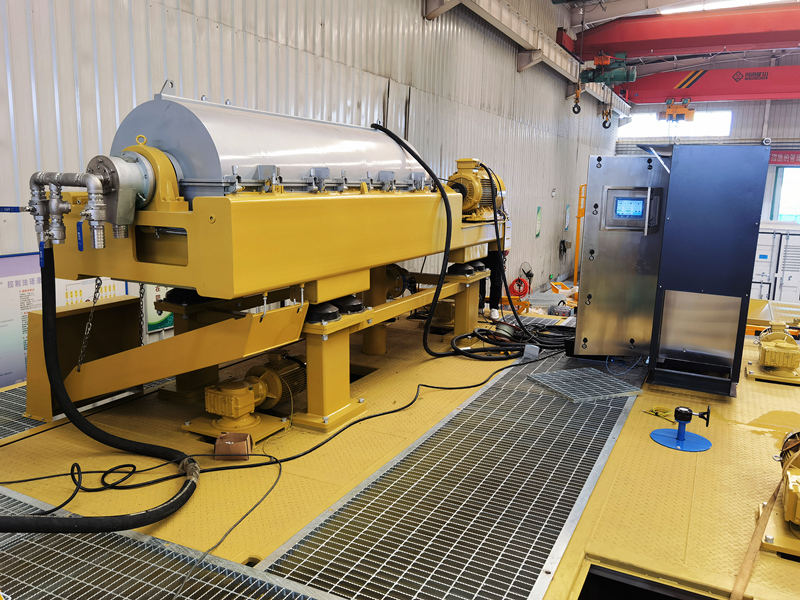

As a leading manufacturer of separation equipment and conveying equipment, GN always pay high attention to the product quality and consider the long-term benefits for our users. We would also like to introduce GN as a professional manufacturer in decanter centrifuge field, GN pays a lot of attention in the selection of raw materials, high-quality centrifugal casting or forging stainless steel materials are used, and for wearing parts, hard alloy protection is used.

GN high-end CNC lathes, CNC centers, and CNC gantry milling machines can better ensure the machining accuracy of centrifuge parts. In terms of the dynamic balance of the decanter centrifuge, in addition to the ordinary low and medium speed dynamic balance, GN also applies a high speed dynamic balance process, which can dynamically balance the centrifuge screw and bowl at the actual working speed of the centrifuge. In terms of market applications, GN decanter centrifuges are widely used in the industry, and the products are exported to more than 60 countries and regions in the world, and have won high praise from customers.

By the way, if you are interested in our products, please check the following items of our company on Alibaba: