When operating a decanter centrifuge, it’s essential to adhere to specific precautions to ensure safe and efficient operation. Continue reading

Category Archives: Decanter centrifuge

GN Will Attend IFAT MUNICH THIS MAY

IFAT MUNICH 2024, recognized as the premier global platform for environmental technology exhibitions, continues its legacy as the foremost trade fair for water, sewage, waste, and raw materials management Continue reading

GN SEPARATION SCORES BIG AT AISAWATER 2024 MALAYSIA WATER EXHIBITION

GN Separation has emerged triumphant from the recently concluded Aisawater 2024 exhibition in Malaysia, marking a significant milestone in its journey of innovation and global expansion. Continue reading

Introduction of no-load test run for decanter centrifuge

The no-load test run for decanter centrifuge is a necessary step for the inspection of decanter centrifuge. The introduction below is recommended by GN Separation.

GN 5m3 Oily Sludge Treatment System for Middle East Customer

GN Separation has effectively supplied a 5m3 oily sludge treatment system recently to a client located in the Middle East. This system is tailored to efficiently manage and extract valuable constituents from the residuals of oil sludge treatment extraction. This delivery signifies another stride in GN’s endeavors to broaden its footprint in global markets, furnishing solutions that uphold both ecological responsibility and resource reclamation.

The system comprises four key components: a premixing tank, the GNZS706 fine Shale Shaker, the GNLW364 three-phase decanter centrifuge, and a containerized chemical dosing system. Each element plays an indispensable role in the system’s functionality, offering crucial processing capabilities across various phases of sludge treatment.

At the onset of the process, the premixing tank readies the oily sludge by blending and homogenizing it, ensuring effective segregation of its constituents. This initial step is pivotal for facilitating the subsequent mechanical separation carried out by the GNZS706 fine shale shaker, streamlining the removal of larger particulate matter and thereby alleviating the burden on subsequent separation stages.

The nucleus of the system, the GNLW364 three-phase decanter centrifuge, assumes control to precisely partition the sludge into oil, water, and solids. Leveraging its high-speed rotational capacity and advanced design, the centrifuge attains remarkable separation efficiency, critical for optimizing oil retrieval and curbing residual waste.

Wrapping up the configuration, the containerized chemical dosing system administers specific chemicals required to dismantle emulsions in the sludge, augmenting separation quality and enhancing the purity of the extracted oil and water.

This installation not only underscores GN Separation’s dedication to furnishing high-caliber environmental solutions but also enhances the operational prowess of its clients within the oil and gas realm. The system’s capacity to enhance oil recovery rates and mitigate environmental repercussions delivers significant value to regions grappling with the complexities of managing by-products from the oil industry.

For further insights into GN Separation’s array of products and their versatile applications, please visit GN Separation Equipment Co., Ltd.

Trouble Shooting Of Decanter Centrifuge Gear Box

Common failures of Decanter centrifuge gear boxes include tooth surface wear, tooth surface gluing and abrasions, tooth surface contact fatigue, bending fatigue and broken teeth. The causes are manufacturing errors, poor assembly, poor lubrication, overload, and operational errors. Due to the characteristics of the structure and working principle of the gear, its vibration signal is very complicated, and the vibration fault diagnosis of it needs to be analyzed in both the time domain and the frequency domain. Whether the gear is in a normal or abnormal state, the frequency of gear meshing stiffness always exists.

Therefore, the gearbox should be diagnosed based on the gearing frequency component of the gear. Due to the complexity of the gear signal, the fault has many effects on the vibration signal, especially due to the effect of amplitude modulation and frequency modulation, there are many sideband structures on the vibration spectrum of the gear, which requires specific analysis during the analysis and diagnosis Components to achieve accurate diagnosis of gearbox faults.

The characteristic frequency of the Decanter centrifuge gear box failure is as follows:

1. The normal frequency spectrum shows the 1X and meshing frequencies of all the rotating shafts. There are speed sidebands on both sides of the gear meshing frequency, and the peak value is small.

2. Gear wear. The natural frequency of the gear appears, and there is a speed sideband of the shaft where the worn gear is located. When the wear is obvious, a higher peak sideband will appear near the meshing frequency.

3. Decanter centrifuge gear eccentricity. There is a sideband of higher amplitude near the meshing frequency, indicating that the gear is eccentric or the shaft is not parallel, and the peak of the meshing frequency increases with the increase of the load.

4. The decanter centrifuge gears are misaligned. The vibration of the second or higher harmonics of the meshing frequency is almost always excited, and the peak value at the 2X or 3X meshing frequency spectrum line is large, and there is a side frequency of the rotation frequency interval.

GN Separation is to Kick off Its Innovative 3-phase Decanter Centrifuge at CIPPE

At the upcoming China International Petroleum and Petrochemical Technology and Equipment Exhibition (CIPPE), GN separation, a professional separation technology provider, will showcase its innovative 3-phase decanter centrifuge.

Show Name: CIPPE (short for China International Petroleum & Petrochemical Technology and Equipment Exhibition)

Date:March 25~27, 2024

Venue:New China International Exhibition Center, Beijing

GN Booth No.: E2168

GN 3-phase decanter centrifuge has attracted the attention of many industries with its excellent performance and unique design. Its bowl are made of duplex stainless steel 2205, and the use of centrifugal casting technology ensures the compactness of the material composition, thus achieving excellent dynamic balance performance, which is crucial for high-speed and stable operation. At the same time, the components that directly contact the processing materials are made of 316L stainless steel, ensuring the durability and corrosion resistance of the machine.

The design of this centrifuge is to efficiently separate heavy liquid phase, light liquid phase and solid residue. It uses the density difference between different materials to achieve 3-phase separation. This function benefits from the diversified centrifugal force generated by the machine, making the separation of various components more precise. The centripetal pump design adopted by the centrifuge achieves precise control over the boundaries of different liquid phases within the device, thereby meeting various separation requirements and ensuring clarity after fluid separation.

It is worth mentioning that the GN 3-phase decanter centrifuge is also equipped with a frequency conversion control cabinet, which can achieve precise control of the centrifuge’s rotational speed and feed rate by adjusting the speeds of the main motor, auxiliary motor, and feed pump. This advanced feature gives the machine high flexibility, allowing it to adapt to various complex operating scenarios.

In terms of application fields, 3-phase decanter centrifuges have broad application prospects in oil sludge treatment systems, edible oil extraction, and kitchen waste management. GN Separation is constantly meeting the growing needs of the industry by relentlessly pursuing innovative technologies and product quality.

We sincerely invite all enterprises and individuals interested in separation technology to visit the GN booth during the CIPPE exhibition to experience the powerful functions of the 3-phase decanter centrifuge and discuss future cooperation opportunities. We believe that through this exhibition, GN will continue to consolidate its leading position in the field of separation technology and contribute more to the sustainable development of the industry.

GN Separation will attend IE Expo China 2024 in Shanghai

GN Separation is excited to announce its participation in the IE Expo in Shanghai next month, and cordially invites friends, customers, and industry colleagues to visit the GN booth to explore GN’s innovative products and engage in technical and commercial discussions.

Show Details:

- Show Name: IE Expo China 2024

- Location: Shanghai New International Expo Centre (SNIEC)

- Expo Date: April 18~20, 2024

- GN Booth: N4-H46\I46 (Hall 4)

During the expo, GN will showcase some of its main industrial separation and conveying equipment. Here’s a brief overview of GN’s featured products:

Sludge Dewatering Centrifuge:

GN will exhibit the GNLW554 model with a 22-inch bowldewatering decanter centrifuge. This high-speed rotating bowl utilizes centrifugal force to efficiently separate solids and liquids based on their different densities. Additionally, GN will showcase the GNLWS364 model, a 3-phase decanter centrifuge suitable for separating light liquid, heavy liquid, and solids. To enhance durability, GN utilizes tungsten carbide plates and bushings for screw blade and solids discharging port protection, thereby extending the machine’s service life.

Disc Stack Separator:

The disc stack separator, also known as a disc stack centrifuge, operates at higher speeds compared to decanter centrifuges. It is typically installed after the decanter centrifuge to separate ultra-fine solids that cannot be removed by the decanter. With the ability to generate higher centrifugal force, the disc stack separator is ideal for slurry clarifying and oil-water separation. GN emphasizes the importance of maintaining slurry feed with solids concentrations below 5% to prevent blockages and ensure smooth operation.

Solid Vacuum Pump:

GN will showcase two models of solid vacuum pump: GNSP40 and GNSP10, each offering different capacities and designs. All models feature a compact structure for easy onsite layout, with the GNSP10 model equipped with wheels for convenient mobility. These pumps operate automatically with preset suction and discharging times, while the GNSP40 model also offers manual operation. Suitable for various material transfers, including high fluidity liquids, low fluidity slurries, and solid powders and gravels, the solid vacuum pump is fully pneumatic-driven for efficient operation.

GN eagerly anticipates meeting you at IE expo China 2024 and looks forward to fruitful discussions and collaborations.

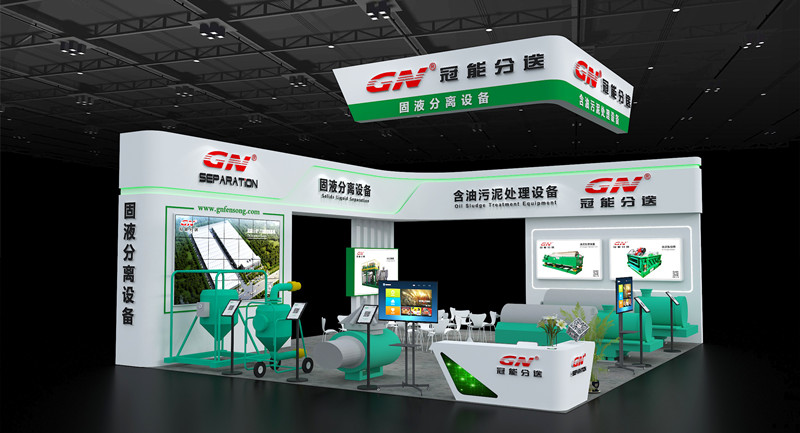

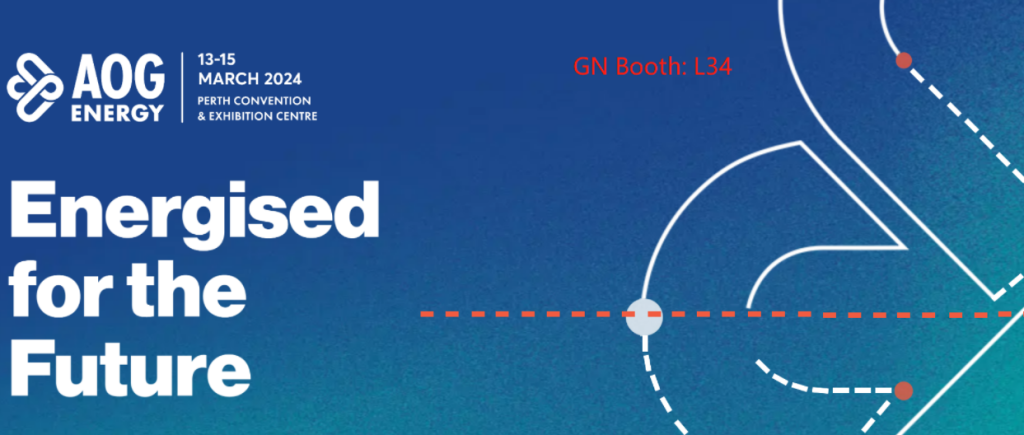

GN Solids Will Participate AOG Energy 2024 in Perth Australia during 13-15 Mar.

GN Solids is glad to attend the coming AOG Energy 2024 (Australasian Oil & Gas Exhibition & Conference) . All clients & friends are sincerely welcomed to visit GN booth for business / technical communicating. GN Solids booth details is as below.

Exhibition Name: AOG Energy 2024

Date: March 13-15, 2024

Booth Number: L34

Location: Perth Convention and Exhibition Centre, Australia

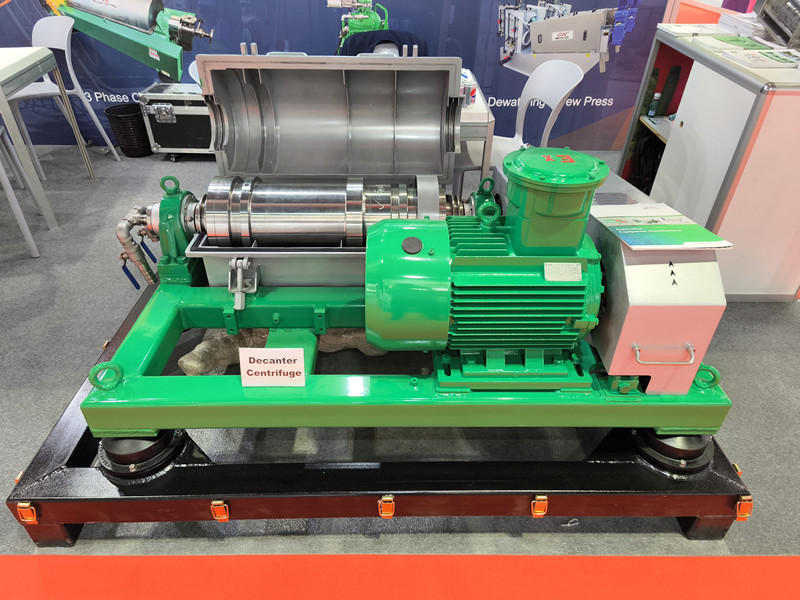

Exhibits: GN 14-inch Bowl Decanter Centrifuge , GN Shaker GNZS752

GN Solids Australia Contact info:

- sales@gnsolidscontrol.com

- +61 467 718 611

- GN Solids Australia Pty Ltd

- Unit 20.256-258 Musgrave Road,Coopers Plains QLD 4108

- https://www.gnsolidsaustralia.com/

- GN waste management decanter centrifuge is the premium centrifuge with the best material configuration. It is the best option for middle term and long term investment because of it’s reliability and working life. This series of decanter centrifuge are popular for the drilling waste management,oil sludge treatment, tank cleaning waste treatment, as well as solids control, barite recovery, Low gravity and high gravity solids separation, dewatering etc..

- GN Shale shaker is first phase solids control equipment in drilling fluids processing system, also known as key solids control equipment in drilling mud system, shale shaker decides performance of the whole solids control system. GN Solids Control can design double shakers and triplicate shakers on single skid according to customers’special requirements and also supply relevant connecting manifold, according to current industry situation, GN provid both third generation linear motion shale shaker and fourth generation balanced elliptical shale shaker.

GNZS linear motion shale shaker absorbed advanced tech at home and abroad,and integrated GN own design. GN complete series shale shaker can meet customers’ variable demand. Clients feedback proved the advantages of this kind of shale shaker: high G-force, wide screen area, compressed structure, cost-effective, etc..

GN looks forward to communicating with more professionals and customers at AOG Energy 2024, learn about their separation requirement to serve customer better set up and sustain longterm nice partnership. GN Solids focuses on customer needs, driven by innovation, improving product quality and service. We believe this exhibition will strengthen ties with customers, partners, and experts, devote GN power to a all better future.

GN SEPARATION WILL ATTEND THE ASIA WATER 2024 EXHIBITION IN APRIL HELD IN MALAYSIA

GN Separation would like to invite all of our clients and friends to join ASIA WATER 2024 Exhibition In April held In Malaysia.

Expo. Website https://www.asiawater.org

Expo. Name: ASIA WATER 2024

Add.: Kuala Lumpur Convention Centre

GN Booth No.: Hall 6, B602

Expo Time: April 23-25th, 2024

ASIAWATER 2024, the region’s leading water & wastewater platform for developing Asia, will return at the heart of modern Malaysia’s city centre, the Kuala Lumpur Convention Centre, from the 23 – 25 April 2024, with the central theme “Water and Climate Change: Innovation for Resilience”.

During this exhibition, GN will show the following equipment:

Decanter centrifuge is a widely used equipment in the field of industrial solid-liquid separation. According to the characteristics of different materials in different industries, GN decanter centrifuge is divided into dewatering, separation, and clarifying decanter centrifuge. With centripetal pump technology, GN decanter centrifuge can also realize the 3-phase separation of liquid, liquid, and solids. GN will bring 2-phase decanter centrifuge GNLW223 to the exhibition.

If you are having a headache when moving high viscosity drilling cuttings, then GN Solids Vacuum Pump is the best choice. GN has built 3 different models: GNSP-10B, GNSP-20B and GNSP-40B. We will show GNSP-10B at the exhibition.

Sludge dewatering screw press

GN screw press sludge dewatering machine is a kind of economic and environmental friendly sludge dewatering equipment. It is a new type of sludge extrusion dewatering equipment by using the principle of screw extrusion, through the strong squeezing force generated by the change of screw diameter and screw pitch, and the tiny gap between the floating ring and the fixed ring, to realize solid-liquid separation.

All of the clients of GN are welcome to visit the ASIA WATER 2024 EXHIBITION. We hope we will have a fruitful meeting and a happy Cooper with you. If you need any support about the operation and maintenance of GN’s equipment, please feel free to contact GN company for our engineers’ best experience and knowledge in the relevant industry. We will do our best to assist your project because just in this way we can establish a stable and long term cooperation. And we can provide on-line support and site instruction for specific situation if needed.