As the global mining sector experiences sustained growth, iron ore processing plants are grappling with escalating demands to ramp up throughput, elevate screening efficiency, and prolong the service life of their equipment. In the face of these formidable challenges, banana vibrating screens have risen to prominence as the preferred solution for iron ore classification, owing to their impressive processing capacity, innovative multi-angle screening design, and outstanding separation capabilities.

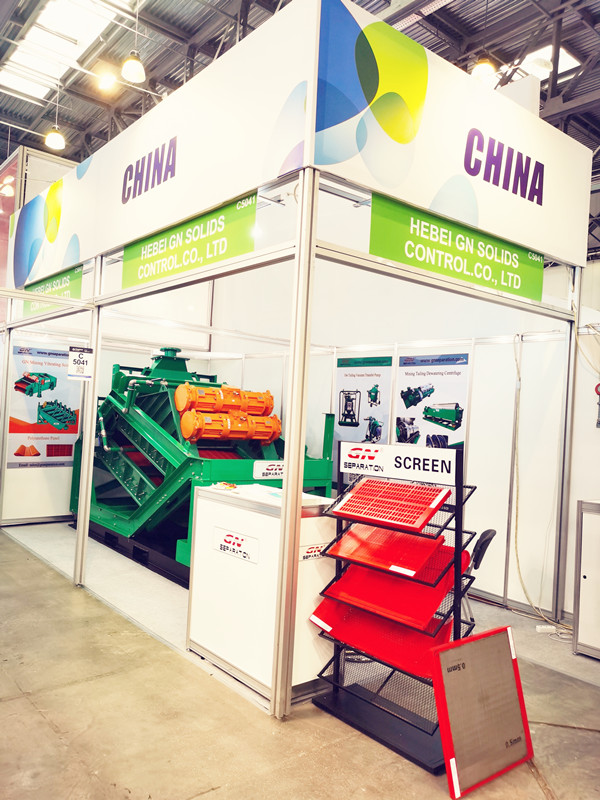

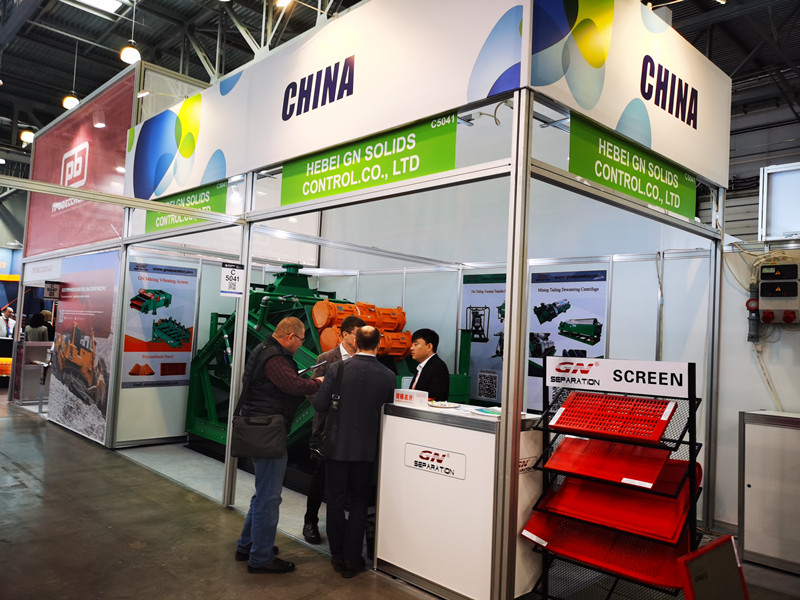

GN Separation has recently completed the production of a Double-Layer Banana Vibrating Screen (Model GNBD3073), specifically engineered for an iron ore classification endeavor. The equipment is primed for dispatch and on-site installation, serving as a shining example of GN’s engineering excellence in heavy-duty screening applications.

The GNBD3073 banana screen is meticulously crafted to endure the rigorous demands of mining operations, encompassing high impact loads, abrasive materials, and uninterrupted use. Its side wallboards feature a non-welded construction, utilizing high-strength alloy steel plates celebrated for their exceptional impact toughness. Rather than relying on conventional welding, imported Huck rivets are employed for hydraulic tension assembly, effectively eradicating welding residual stress and substantially enhancing structural reliability and fatigue resistance.

To guarantee stable operation and an extended service life, GN engineers harnessed the power of finite element analysis (FEA) to refine both the structural design and vibration parameters. This rigorous approach enables the screen to avoid natural frequencies at all operational stages, mitigating the risk of resonance and minimizing vibration-induced damage, thereby prolonging the equipment’s overall lifespan.

Beneath the screen deck, the cross beams are ingeniously designed with rectangular tubes, providing a sturdy and stable support framework. Conversely, the excitation beam box showcases a lightweight design without sacrificing strength or toughness. Key welded components undergo post-welding heat treatment to alleviate stress and bolster long-term operational stability.

For enhanced resistance to wear and corrosion, the beam surfaces are coated with polyurea using cutting-edge spray equipment imported from the United States. Furthermore, rubber protective components are strategically positioned in areas susceptible to intense impact and abrasion. These measures collectively fortify the screen’s resilience against erosion and wear, ensuring dependable performance in the demanding realm of iron ore screening.

The GNBD3073 is propelled by a high-efficiency helical gear box-type exciter, which generates a colossal excitation force while maintaining minimal noise levels and stable operation. The exciter is meticulously engineered for longevity and reduced maintenance requirements. Its eccentric blocks are situated outside the exciter box, granting operators the flexibility to effortlessly adjust the vibration amplitude by modifying the counterweight configuration to accommodate diverse materials and process conditions.

To cater to a broad spectrum of customer needs, GN banana vibrating screens are offered as a versatile series of products adaptable to various production capacities and process flows. The screen incorporates modular polyurethane screen panels, renowned for their exceptional wear resistance, versatility, and rapid replacement capabilities. This modular design significantly slashes downtime and curtails overall operating and maintenance costs for customers.

With this triumphant application in iron ore processing, GN Separation reiterates its unwavering commitment to delivering high-efficiency, reliable, and cost-effective screening solutions to the global mining industry. GN remains steadfast in its pursuit of technological innovation and product optimization, continuously endeavoring to provide advanced vibrating screening equipment that empowers customers worldwide to achieve efficient and sustainable mineral processing operations.