Recently, GN Separation successfully completed factory acceptance testing (FAT) of a GNLW654 decanter centrifuge. This advanced unit, designed for superior operational flexibility and durability, is now preparing for shipment to a key client in Europe.

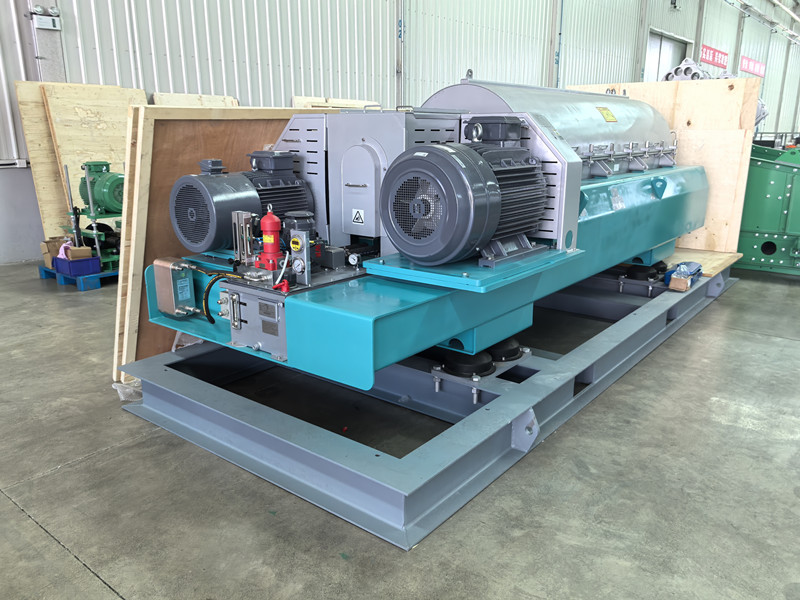

Dual-Motor Drive System: Precision Control in Dynamic Environments

At the heart of the GNLW654’s performance is its dual-motor drive configuration, which allows operators to independently adjust both the main bowl speed and the differential speed between the bowl and the screw conveyor. This flexibility enables precise process control, optimizing separation efficiency across a wide range of feed conditions. Whether dealing with viscous slurries, abrasive tailings, or fluctuating feed rates, the dual-motor system ensures fast response to process variations, minimizing downtime and maximizing throughput.

Continuous Lubrication: Reliability for 24/7 Operation

To ensure uninterrupted performance in demanding continuous-duty applications, the GNLW654 decanter centrifuge is equipped with a fully automated thin-oil lubrication system. Unlike traditional grease-based solutions, this closed-loop system continuously circulates and cools lubrication oil to the main bearings, reducing friction, dissipating heat, and preventing premature wear. This design significantly extends bearing life, lowers maintenance frequency, and reduces total lifecycle costs.

Tungsten Carbide Wear Protection: Built for Longevity

Given the abrasive nature of many slurry applications, GN Separation equips the GNLW654 decanter centrifuge’s rotating assembly with tungsten carbide wear plates and liners at critical contact points, including the screw flights and feed zone. These components offer exceptional resistance to erosion and corrosion, dramatically extending service intervals and lowering replacement costs.

Seamless Integration with Flocculation Dosing Systems

The GNLW654 decanter centrifuge achieves peak efficiency when integrated with GN Separation’s polymer dosing units. In municipal wastewater treatment, this combination enhances floc formation, improving the capture and dewatering of biological sludge.

In mining applications, pairing the centrifuge with a flocculation system has proven transformative. Recent field trials at a copper mine in Mexico showed a substantial reduction in the solids content of clarified tailings slurry, significantly cutting waste handling and disposal costs.

Global Impact: From Municipal Infrastructure to Mining Operations

GN Separation’s decanter centrifuges are trusted across multiple industries for their reliability and performance. The GNLW654, with its modular design and scalable capacity, is attracting attention from European municipalities seeking to modernize wastewater treatment facilities and from global mining companies looking to improve tailings management.

As the GNLW654 embarks on its journey to Europe, GN Separation reaffirms its commitment to delivering innovative, durable, and integrated separation solutions that help clients achieve cleaner, more efficient, and more sustainable operations.