This October, the global mining community will converge in Beijing for the highly anticipated 21st China Coal & Mining Expo (CCME 2025). As a premier event in the industry, CCME 2025 is dedicated to driving progress in coal and mineral extraction technologies.

Event Snapshot

Scheduled to take place from October 28 to 31, 2025, at the Capital International Convention and Exhibition Center in Shunyi, Beijing, CCME 2025 promises to be a vibrant hub of activity. The exhibition is set to attract a wide array of exhibitors, encompassing well – known domestic and international manufacturers, cutting – edge technology providers, and seasoned industry experts. Over the four – day span, the focus will be on sustainable mining practices, automation, and equipment innovation. Attendees will gain access to the most up – to – date and efficient coal mining solutions, making it an invaluable event for anyone involved in the sector.

GN Separation’s Presence

GN Separation is proud to be among the exhibitors and will be located at Booth A4601. The company is gearing up to present a series of advanced equipment designed to address critical challenges in coal preparation, tailings management, and underground mining operations.

1. Large Flip – Flow Vibrating Screen: A Game – Changer in Screening

At the heart of GN Separation’s exhibit lies the Large Flip – Flow Vibrating Screen, a revolutionary screening technology specifically engineered for fine – grained and sticky materials. Traditional vibrating screens often struggle when dealing with fine coal, wet ore, or clay – rich substances, frequently experiencing clogging and inefficient separation. GN’s flip – flow design, however, overcomes these obstacles. By combining a flexible polyurethane screen surface with a double – mass near – resonance working principle, it effectively prevents screen blinding and pegging. This ensures a consistent and reliable throughput. In the context of coal mining, this equipment is particularly valuable for pre – screening raw coal before the washing process. By doing so, it reduces the burden on subsequent operations, streamlining the overall coal preparation workflow.

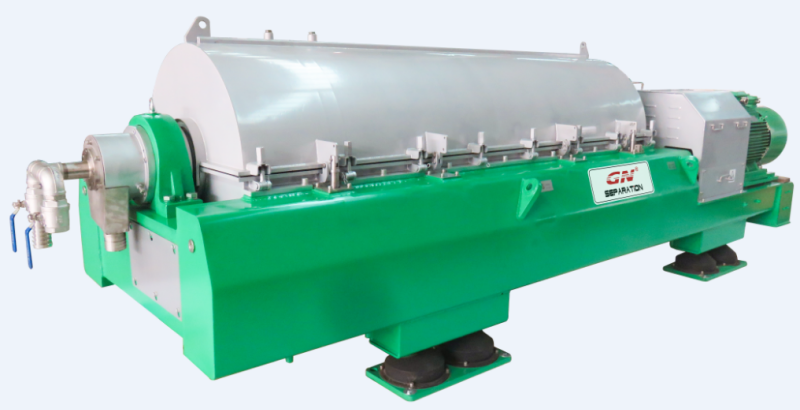

2. Tailing Dewatering Decanter Centrifuge: An Eco – Friendly Solution for Tailings Disposal

Tailings disposal is one of the most pressing environmental issues in the mining industry. GN Separation’s Tailing Dewatering Decanter offers a sustainable and efficient solution. It works by reducing the water content in mine waste, separating solids from liquids to produce a dry, stackable cake. This not only minimizes the amount of land required for waste storage but also significantly lowers the risk of leachate, which can have detrimental effects on the environment. In coal preparation plants, the decanter centrifuge plays a crucial role in facilitating the recycling of process water, thereby reducing the consumption of freshwater. With a capacity of up to 100 cubic meters per hour, it is an ideal choice for mid – to – large – scale mining operations that are looking to improve waste management while complying with ESG (Environmental, Social, and Governance) standards.

3. Underground Coal Sump Slurry Separation System: Tackling Underground Mining Challenges

Underground mining environments pose a set of unique challenges, including limited space, water inflow, and the need for rapid and efficient slurry handling. GN Separation’s Underground Coal Sump Slurry Dewatering System is designed to meet these challenges head – on. It integrates a compact decanter centrifuge with a pre – screening module to effectively treat the muddy water generated during roadway tunneling, coal extraction, and dust suppression. The system begins by separating coarse solids using a screening cyclone combination unit. Subsequently, the slurry is transferred to a dewatering centrifuge for fine particle separation. This process eliminates the need for manual sump dredging, ensuring unobstructed mine drainage. Moreover, it supports safe, efficient, and eco – friendly mining operations. Typically designed in a modular fashion, the system is easy to transport, install, and relocate, enabling it to be used in a mobile capacity.

GN Separation: Pioneering a Sustainable Mining Future

With over a decade of experience in separation technologies, GN Separation has established itself as a trusted and reliable partner for mining companies around the world. Its participation in CCME 2025 is a testament to its unwavering commitment to innovation and customer – centric design. Visitors to Booth A4601 will have a unique opportunity to engage with technical experts, witness live demonstrations of the equipment in action, and explore customized solutions tailored to their specific operational needs. We extend a warm invitation to all attendees to visit GN at the expo and discover how our cutting – edge technologies can transform their mining operations.