At the recently concluded IE EXPO CHINA 2025, GN Separation drew significant attention, forging new business partnerships and deepening technological exchanges with both longstanding collaborators and first-time visitors. The exhibition served as a valuable platform for the company to highlight its latest innovations in environmental water treatment and solid waste management.  GN Separation presented three flagship products at the event—each designed to tackle pressing challenges in environmental engineering: Solids Vacuum Pump, Fully Hydraulic Decanter centrifuge, 3 Phase Decanter Centrifuge. These systems showcased GN’s commitment to developing reliable and efficient solutions for diverse applications, from municipal sludge treatment to complex oil-water-solid separation.

GN Separation presented three flagship products at the event—each designed to tackle pressing challenges in environmental engineering: Solids Vacuum Pump, Fully Hydraulic Decanter centrifuge, 3 Phase Decanter Centrifuge. These systems showcased GN’s commitment to developing reliable and efficient solutions for diverse applications, from municipal sludge treatment to complex oil-water-solid separation.

Solids Vacuum Pump: Versatile Material Handling

The fully pneumatic Solids Vacuum Pump stood out as a highly adaptable solution for transporting challenging materials in both industrial and municipal sectors. Key applications include:

Sewage Sludge Removal: Cleaning sedimentation tanks in wastewater treatment plants.

Construction Slurry Transport: Handling heavy mud from construction sites.

Solid Waste Conveyance: Moving granular solids like sand, powders, and residues.

With no electrical components, the pump is ideal for explosive or hazardous environments, offering both operational safety and reduced maintenance costs. Its ability to handle materials of varying densities and particle sizes makes it a versatile asset for dynamic waste management systems.

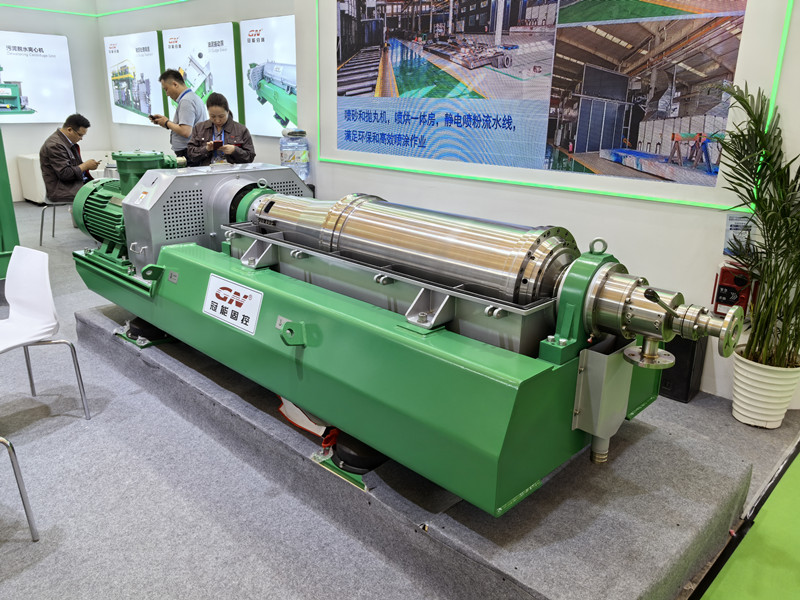

Fully Hydraulic Decanter Centrifuge: Adaptive Dewatering Technology

GN Separation’s Fully Hydraulic Decanter centrifuge offers a dynamic alternative to traditional electric models. Designed to adjust torque in real time based on feed characteristics, it delivers optimized dewatering performance across variable sludge compositions. Key benefits include:

Adaptive Torque Control: Maintains consistent cake dryness despite fluctuating input.

Maintenance-Free Hydraulic Gearbox: Reduces downtime and long-term servicing costs.

Explosion-Proof Design: Certified for hazardous areas such as oilfields and chemical plants.

This technology is increasingly favored by municipalities and industrial facilities seeking durable, high-efficiency dewatering systems.

3 Phase Decanter Centrifuge: Precision Separation for Complex Waste Streams

The 3 Phase Decanter Centrifuge addresses the growing need for precise, simultaneous separation of light liquid, heavy liquid, and solid phases. It is ideally suited for:

Kitchen Waste Oil Recovery: Extracting edible oils from food processing waste.

Oil-Water Separation: Enhancing industrial wastewater treatment.

Oily Sludge Treatment: Recovering valuable oils in refineries and petrochemical plants.

By reducing waste volume and reclaiming resources, this centrifuge supports circular economy principles and helps users meet stringent environmental regulations.

Strategic Engagements: Advancing Innovation through Collaboration

In addition to showcasing its technologies, GN Separation engaged in strategic discussions with industry leaders and technical experts. These conversations explored collaboration opportunities in emerging markets and joint research initiatives. The company also highlighted ongoing partnerships with universities and R&D institutions, reinforcing its dedication to advancing sustainable separation technologies.

With a strong presence at IE EXPO CHINA 2025, GN Separation continues to position itself at the forefront of environmental innovation—delivering solutions that balance performance, efficiency, and environmental responsibility.