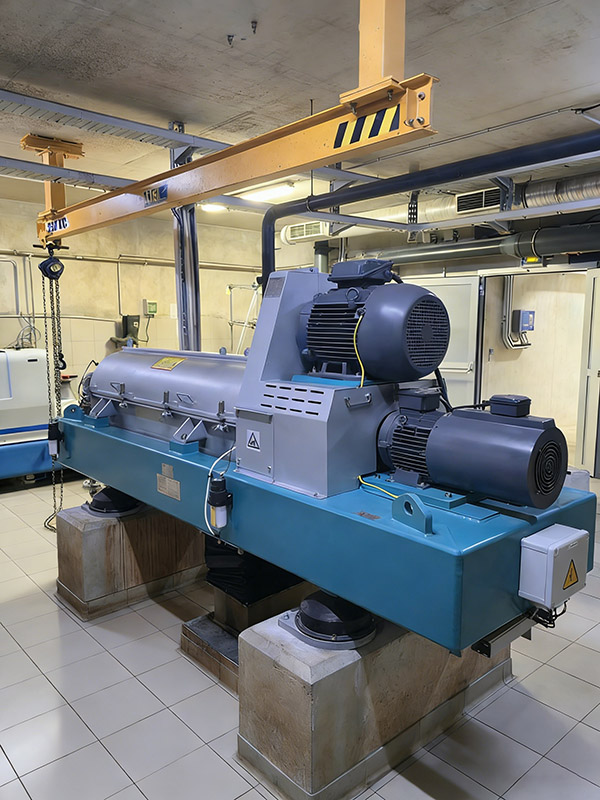

GN Separation, a leading Chinese manufacturer specializing in solid-liquid separation equipment, achieved a significant milestone by successfully installing and commissioning its decanter centrifuge at a sewage treatment plant (STP) in France. With the invaluable assistance of its local partner, the project proceeded without a hitch, and the centrifuge is now running smoothly, fully meeting all performance benchmarks. This successful commissioning has garnered glowing praise from the end user, who commended the equipment’s reliability and outstanding operational performance.

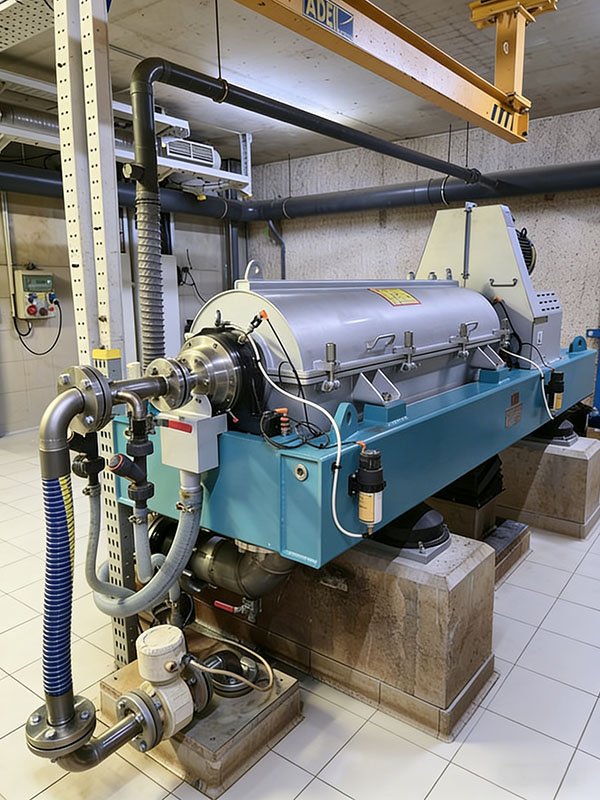

This project underscores GN Separation’s unwavering commitment to delivering cutting-edge wastewater treatment solutions on a global scale. By working hand-in-hand with its local partner in France, GN Separation ensured that every stage of the installation process, from mechanical assembly to system calibration, adhered to the most stringent standards. The partner’s professional guidance in maintenance and installation was instrumental in seamlessly integrating the decanter centrifuge into the plant’s existing operations.

The project serves as a prime example of the effective utilization of GN’s dewatering decanter centrifuge in municipal wastewater treatment processes, especially in sludge dewatering operations. Thanks to the support of the local French partner, the plant can now count on stable installation, operation, and maintenance services, guaranteeing consistent performance over the long haul. This collaboration highlights GN Separation’s dedication to providing practical, reliable solutions and comprehensive technical support to wastewater treatment facilities throughout Europe.

GN Separation’s decanter centrifuge is engineered for optimal sludge dewatering efficiency, high throughput capacity, and minimal maintenance requirements. Its robust construction ensures stable operation even in the most challenging conditions, making it an ideal choice for both municipal and industrial wastewater treatment facilities. The successful deployment of this equipment in France stands as a testament to its versatility and GN Separation’s ability to tailor solutions to meet the unique needs of different regions.

With the completion of this project, GN Separation continues to solidify its presence in Europe, proving that strategic partnerships can facilitate the efficient and effective implementation of advanced engineering solutions. The company remains steadfast in its pursuit of innovation, operational excellence, and providing end users with sustainable solutions for sludge management and wastewater treatment.