Johannesburg, South Africa — As the mining industry embraces new technological advancements and sustainable practices, Electra Mining Africa 2024 is set to be a landmark event for global stakeholders. Scheduled from September 2nd to 6th, 2024, at the renowned Expo Centre in Nasrec, Johannesburg, this biennial exhibition will be a hub of innovation, networking, and collaboration for the African mining and minerals processing sector. Continue reading

Author Archives: admin

GNLW224 DECANTER CENTRIFUGE FOR OVERSEAS SALT CHEMICAL APPLICATION

GN Separation has recently completed the assembly of two GNLW224 decanter centrifuges, known for their compact design that merges innovation with durability. These versatile machines are ideal for various industries, including environmental protection, salt chemicals, and oil & gas exploration.

The GNLW224 decanter centrifuge can exemplify GN’s dedication to technological excellence, featuring a bowl diameter of 220mm and a length-to-diameter ratio of 4.2. This design optimizes space while maintaining top-tier performance. With a rotational speed of up to 5000 RPM, the centrifuge delivers high-speed separation, generating powerful centrifugal forces to ensure superior separation efficiency. The bowl, made from duplex stainless steel 2205 through a centrifugal casting process, offers enhanced balance and resilience, capable of withstanding harsh operating conditions while reducing vibrations and extending the machine’s lifespan.

Supporting Diverse Industries

- Environmental Protection: Sludge Dewatering

In the environmental sector, GN’s decanter centrifuge is widely used for sludge dewatering. Its ability to efficiently separate water from sewage sludge significantly reduces waste volume, lowering transportation costs and enabling more eco-friendly sludge management. The improved sludge dryness also supports energy recovery through anaerobic digestion, contributing to the circular economy in wastewater treatment facilities.

- Salt Chemicals: Crystal Salt Dewatering

In the salt chemicals industry, the decanter centrifuge is crucial for crystal salt dewatering. Salt producers depend on precise separation techniques to achieve high-purity salt crystals, and this machine excels in delivering low moisture content in the final product, enhancing both quality and profitability. Its durable design efficiently handles abrasive salt particles, ensuring consistent performance over long periods.

- Oil & Gas: Drilling Mud Recycling

The oil and gas industry generates significant amounts of contaminated drilling mud containing valuable drill cuttings and fluids. The decanter centrifuge offers an effective solution for separating these materials, reducing waste disposal costs and facilitating mud recycling. By separating solid particles from fluids quickly and thoroughly, it minimizes the need for fresh mud and improves overall drilling efficiency. The centrifuge’s high-speed operation ensures continuous processing, supporting uninterrupted drilling activities.

For more information about the decanter centrifuge, please contact GN Separation.

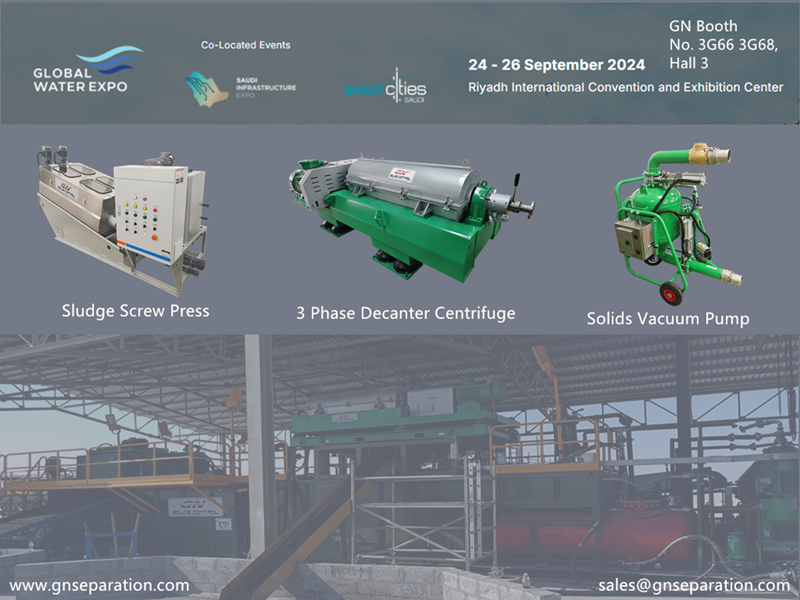

GN Separation will attend Global Water Expo this September in Riyadh, Saudi Arabia

As Saudi Arabia continues to emphasize sustainable water management and environmental conservation, the upcoming Global Water Expo in Riyadh, scheduled for September, is set to be a key platform for unveiling the latest innovations in water technology and treatment solutions. GN Separation is prepared to make a significant impact at this event by presenting its cutting-edge sludge dewatering equipment and comprehensive oily sludge treatment solutions.

Event Details:

- Event Name:Global Water Expo

- Date:24-26 September 2024

- Location:Riyadh International Convention and Exhibition Center

- Booth:3G66-3G68, Hall 3

Innovative Sludge Dewatering Solutions

GN Separation‘s presence at the Global Water Expo highlights its dedication to advancing sustainable practices in the water and wastewater treatment industry. The company will showcase its leading sludge dewatering technologies, including the Sludge dewatering decanter centrifuge and Screw Press, which are recognized for their high efficiency, automation, and minimal environmental impact. Additionally, GN will feature the Sludge Vacuum System, designed to ensure safe and efficient sludge transportation within treatment plants, reducing contamination risks and enhancing operational efficiency.

Tackling Oily Sludge Challenges

In response to the rising concern over oily sludge from the petroleum industry, GN Separation has developed a comprehensive oily sludge treatment system that integrates both physical and chemical processes. This system effectively reduces the oil content in sludge, transforming it into a more manageable and eco-friendly form, while also promoting the recovery of valuable resources such as oil and water for reuse.

Collaborating for a Sustainable Future

By showcasing these innovative technologies and solutions at the Global Water Expo, GN Separation aims to foster collaborations with industry leaders, policymakers, and researchers. The company is committed to working together with the global community to address the challenges of water scarcity and pollution through shared knowledge and joint efforts. GN eagerly anticipates meeting you at Global Water Expo 2024 and looks forward to our fruitful discussions and collaborations.

One Batch of Screw Conveyors nearly Complete Assembling

At GN Separation, progress is underway as a new batch of Screw Conveyors nears completion in our assembly line. These screw conveyors are integral components for efficient material handling in various industrial processes, including drilling fluid management and waste treatment. Continue reading

GN 5-Deck Stack Vibrating Screens Nearly Ready for Shippin to Customer Site in Central Asia

GN Separation has recently completed the assembly of a batch of five-deck stack vibrating screens destined for a lithium mining operation in Tajikistan, commissioned by China Lithium Corporation as part of their international ventures into lithium spodumene deposits. This partnership underscores GN Separation’s role in enhancing ore screening capabilities at overseas mining sites. Continue reading

A batch of sludge transfer pumps waiting to be shipped to overseas clients

GN Separation has successfully completed the assembly and shipment of a significant batch of sludge transfer pumps for international clients. Featuring two advanced technologies – the screw pump and the solid Vacuum Pump – this range underscores GN Separation’s expertise in designing efficient and dependable equipment for sludge management and material handling. Continue reading

GN Large Linear Vibrating Screens Ready for Shipping to the Domestic Iron Mine

GN Separation successfully manufactured four large linear dewatering vibrating screens this week, which will be deployed in domestic iron ore mines. These screens are essential for the mining industry, as efficient screening and dewatering of materials are crucial for ensuring smooth and cost-effective operations. Continue reading

Oily Sludge Treatment Decanter Centrifuge System for South America Client

GN Solids Control has successfully manufactured an advanced oily sludge treatment decanter centrifuge system to a long-term partner and client in South America. This system is specifically designed to tackle the complex challenges associated with waste oily sludge treatment, offering an efficient and environmentally friendly solution. Continue reading

GN Dewatering Decanter Centrifuges for Overseas STP Project

GN Separation recently completed the production of a significant batch of advanced sludge dewatering decanter centrifuges, slated for deployment in international wastewater treatment facilities. This achievement underscores the company’s steadfast commitment to tackling global water treatment challenges head-on. Continue reading

GNLW-364FT DEWATERING CENTRIFUGE FOR OVERSEAS PROJECT OF CRYSTAL SALT DEWATERING

GN Separation has recently finalized production on two advanced crystal salt dewatering decanter centrifuges, marking a significant milestone in the company’s commitment to delivering high-performance separation solutions. These centrifuges are slated for shipment to an esteemed overseas client, underscoring GN’s reputation as a reliable provider in the industry. Continue reading