GN Separation has recently completed the assembly of a containerized sludge dewatering system designed specifically for oil-contaminated soil remediation. This system is set to be shipped to a client in the Middle East and offers an innovative solution for managing the sludge generated during soil washing processes, particularly in oil spill cleanups and industrial site rehabilitation.

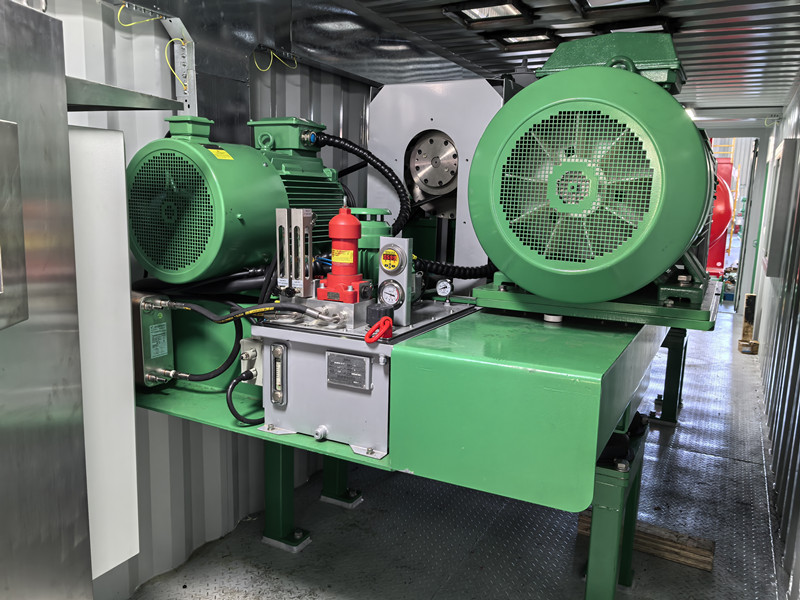

The core of this turnkey system is its ability to efficiently separate the solid and liquid components of the slurry created during the soil washing phase. Housed within a standard 40-foot shipping container, the system incorporates a range of equipment optimized for mobility, ease of installation, and reliable performance. At the heart of the system is the GNLW654-VFD sludge dewatering decanter centrifuge, engineered by GN Separation to meet the challenges of this application.

Equipped with a Variable Frequency Drive (VFD) control cabinet, the GNLW654-VFD decanter centrifuge offers operators exceptional flexibility in adjusting the operational parameters of the primary and secondary motors, feed pump, and polymer dosing pump. This feature enables fine-tuning to accommodate varying feedstock characteristics, enhancing treatment efficiency, maximizing the quality of dewatered sludge (or mud cake), and minimizing water content.

Given the abrasive nature of oil-contaminated soil sludge, GN Separation has incorporated tungsten carbide plates and sleeves into the centrifuge’s screw conveyor and slag discharge port. These wear-resistant materials protect critical components from premature wear, extending the equipment’s service life, reducing maintenance costs, and ensuring operational continuity.

The system also includes a feed Screw pump and a dosing Screw pump from Netzsch, a leading German manufacturer known for its reliable, high-performance industrial pumps. These components ensure precise and consistent delivery of the sludge feed and flocculant chemicals necessary for optimal solid-liquid separation.

The screw conveyor, another essential element of the system, has been custom-designed to match the required throughput and the site’s layout. This design ensures seamless integration into the containerized setup and facilitates easy installation and user-friendly operation, crucial for remote locations with challenging logistics, such as those in the Middle East.

By encapsulating the entire sludge dewatering process within a single, portable container, GN Separation has overcome common logistical and operational challenges typically encountered in international projects. This containerized approach simplifies transportation, reduces on-site civil work, and accelerates the commissioning phase, resulting in cost savings and faster project timelines.

Additionally, the system’s modular design allows for future upgrades or adjustments, making it easy for the client to adapt to evolving treatment needs or regulatory requirements without significant rework. This forward-thinking approach highlights GN Separation’s commitment to providing sustainable, future-proof solutions for environmental challenges.

For more information on GN Separation’s containerized sludge dewatering system for oil-contaminated soil remediation, please feel free to contact us.