GN Solids Control is thrilled to announce a major supply to the Horizontal Directional Drilling (HDD) industry: three complete GNMS – 1000 Mud Recycling Systems and forty high – wear – resistant slurry pumps have been successfully dispatched to a major client. This large – scale order clearly demonstrates our ability to provide comprehensive, integrated solutions that significantly boost operational efficiency and reliability in trenchless drilling projects.

Main Elements of the Shipment

Three Sets of GNMS – 1000 Mud Recycling Systems

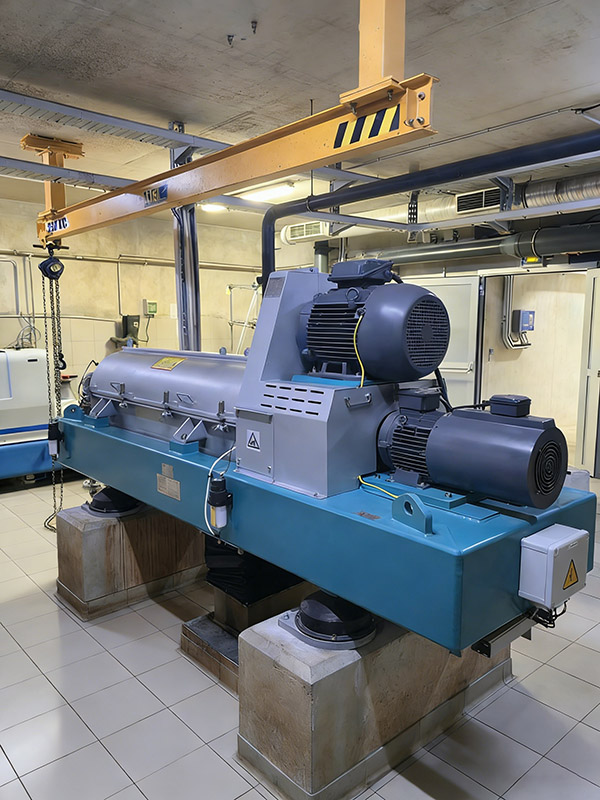

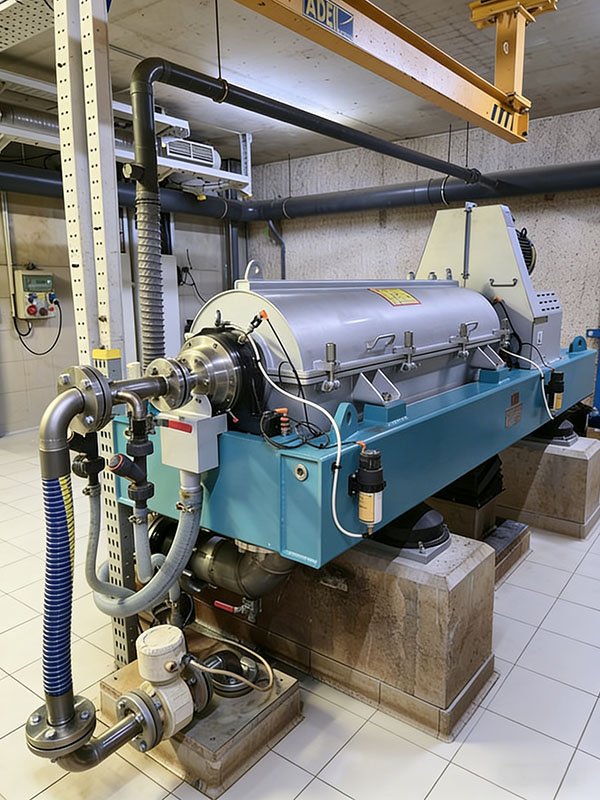

Each GNMS – 1000 Mud Recycling System is a fully – integrated, self – sufficient unit crafted for maximum efficiency. It incorporates a shale shaker, mud cleaner, mud tank, slurry pumps, and mud agitators into one cohesive package. This all – inclusive design not only offers thorough drilling fluid purification and mixing but also provides sufficient storage capacity. It is specifically engineered to handle the rigorous demands of complex and high – volume HDD operations, ensuring optimal fluid performance throughout the entire project.

Forty Units of Submersible Slurry Pumps

These forty slurry pumps, which complement the mud systems, are constructed to withstand harsh conditions. Equipped with high – chrome alloy pump casings and impellers, they are designed for excellent abrasion resistance and an extended service life. Their sturdy, low – maintenance construction makes them perfect for the continuous transfer of drilling fluid from mud pits in HDD applications. This helps prevent costly disruptions and ensures smooth project execution.

This shipment is a prime example of GN Solids Control’s dedication to delivering end – to – end drilling fluid management solutions. Our services cover everything from precise solids separation and cleaning to reliable fluid transfer. By providing such integrated packages, we assist our clients in reducing overall operational costs, minimizing downtime, and greatly enhancing project reliability.

We take great pride in contributing to the success of major HDD projects around the globe and are committed to continuously developing equipment that can meet the ever – changing challenges of the trenchless technology industry.