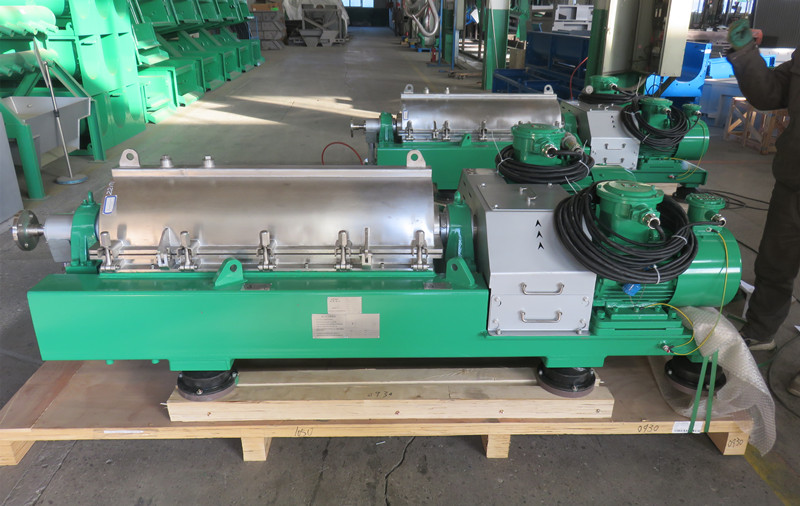

Decanter centrifuge is a kind of centrifuge. It is a kind of mud-water mixture that enters the drum through the feed pipe and the screw discharge port. Under the action of the centrifugal force generated by the high-speed rotation of the main engine, the solid particles with larger specific gravity are deposited on the inner wall of the drum, and the spiral blades moving relative to the drum successively scrape the solid particles deposited on the inner wall of the drum and push them out. The slag outlet, the separated clear liquid flows out of the drum machine through the opening of the weir plate.

1. What are the main components of the screw conveyor in the decanter centrifuge?

The screw conveyor of the Decanter centrifuge contains two parts: the drum and the screw, and the screw includes the cylinder and the pusher blade. On the cylinder, there is a feed end and a clear liquid outlet end, which are used to feed materials and flow out the clear liquid after separation.

2. Why can the Decanter centrifuge be used in petrochemical and waste treatment?

Because the decanter centrfuge has the characteristics of compact structure, low energy consumption, strong production capacity, and good adaptability to materials. And with the continuous development of science and technology, the centrifuge has been greatly improved and advanced in terms of structure, performance and technical parameters, and its separation effect has also been improved, so it is used in petrochemical and The treatment of the three wastes is very suitable.

3. Can the decanter centrifuge be used as the main engine of sludge dewatering?

If it is used for sludge dewatering, it is very suitable, and if it has a large aspect ratio and a fully enclosed operation is selected, then it can have a good use effect, because its It has advantages that other sludge dewatering equipment does not have.

4. What is the process of desilting using a decanter centrifuge in a sewage treatment plant?

In the wastewater treatment plant, in the treatment of activated sludge, the whole process of using a decanter centrifuge to desludge is to drive the high-speed rotation of the sludge through a high-speed rotating drum, and then generate centrifugal force to make the sludge The sedimentation of the solid particles accelerates and concentrates on the wall of the drum. Then, through the spiral, the formed mud cake is scraped to the small end of the rotating drum, so that it can be discharged, thereby completing the desliming work.

5. What is the main use of the decanter centrifuge? In addition, what are the unloading conditions of the decanter centrifuge?

Decanter centrifuge is mainly used to remove impurities and suspended solids in the liquid to achieve the role of purification. The general decanter centrifuge, its discharge conditions, mainly including cone angle and bowl speed.