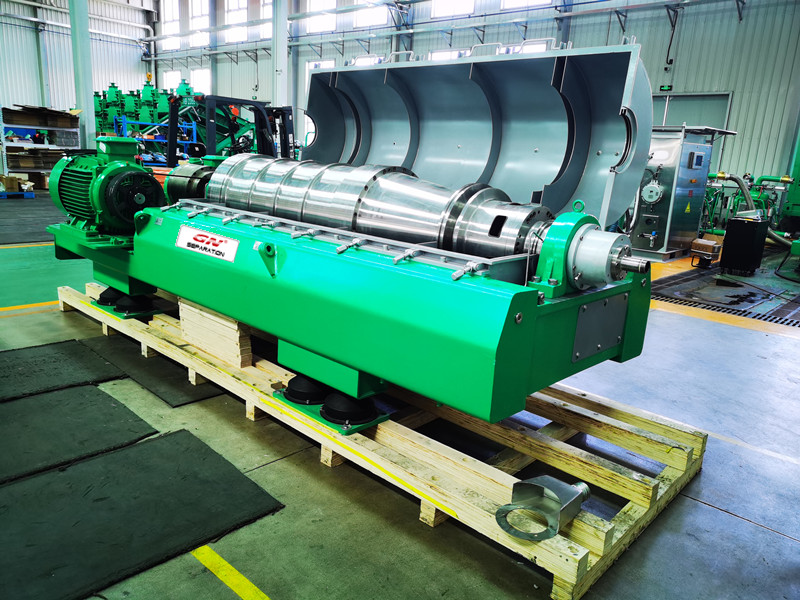

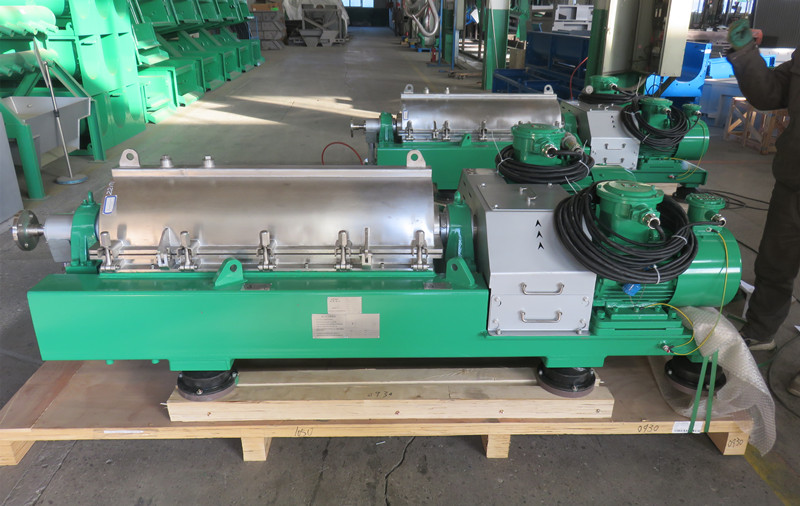

During the operation of a decanter centrifuge, many users encounter the issue of reduced dewatering efficiency. A common symptom is the prolonged dewatering time, with the resulting solids remaining too wet. This often occurs as solids accumulate inside the centrifuge bowl, affecting the separation performance and increasing cycle duration. Fortunately, there are several ways to optimize and enhance the dewatering capacity of the decanter centrifuge.

1. Increase Rotational Speed and Optimize Drum Design

One of the most effective methods is to increase the rotational speed of the centrifuge drum—within the safe operational limits and provided the materials are non-corrosive or only mildly corrosive. Higher centrifugal force promotes more efficient separation of solids from the liquid phase. Additionally, expanding the filtration surface inside the bowl can significantly enhance water discharge. For example, installing a fine mesh lining or a V-shaped filter baffle increases the permeability and accelerates the dewatering process.

2. Reduce Material Load per Cycle

Another approach is to minimize the amount of feed material per cycle. By reducing the volume of sludge processed at one time and using a more frequent discharge cycle (i.e., “less per run, more runs”), the centrifuge can maintain optimal working conditions and improve overall performance.

3. Modify the Material Characteristics

For viscous or fine-particle sludge, washing the feed (as allowed by the process) and increasing the particle size of the solids can help. The use of flocculants is especially critical—selecting the right type, concentration, and dosage can drastically improve the separation rate. Adjusting the flocculant’s mixing intensity and direction also contributes to a better result.

4. Fine-Tune Operating Parameters

To further boost dewatering performance, it is essential to adjust several key operating parameters:

Bowl speed

Scroll speed and differential (torque curve)

Thickness of the liquid ring layer

Flocculant properties and dosage

Solid loading rate

Field experience has shown that the liquid ring thickness and the scroll speed differential are among the most influential parameters in improving sludge dryness and reducing moisture in the cake.

Maintenance Tips for Long-Term Performance

Regular maintenance is vital to keep your decanter centrifuge running at peak efficiency:

After operation, clean the decanter centrifuge chamber and wipe away any condensed water.

Keep the machine door open after use to allow the internal temperature to return to normal.

Balance all samples before starting centrifugation to avoid mechanical stress.

Disinfect and sterilize the unit as needed, especially when handling biologically active or hazardous materials.

By optimizing both mechanical settings and material preparation, users can greatly improve the dewatering efficiency of decanter centrifuges, reduce maintenance costs, and ensure more reliable operation in demanding industrial environments.