GN Separation is proud to introduce the GNLW454GT Mud Dewatering decanter centrifuge, an advanced and robust solution engineered for the efficient treatment of hydrovac slurry and directional drilling mud. Designed to meet the growing demands of utility construction, trenchless drilling, and hydroexcavation projects, this high-performance decanter centrifuge plays a central role in modern waste management systems where reliable solids–liquid separation is essential. Continue reading

Tag Archives: Decanter centrifuge

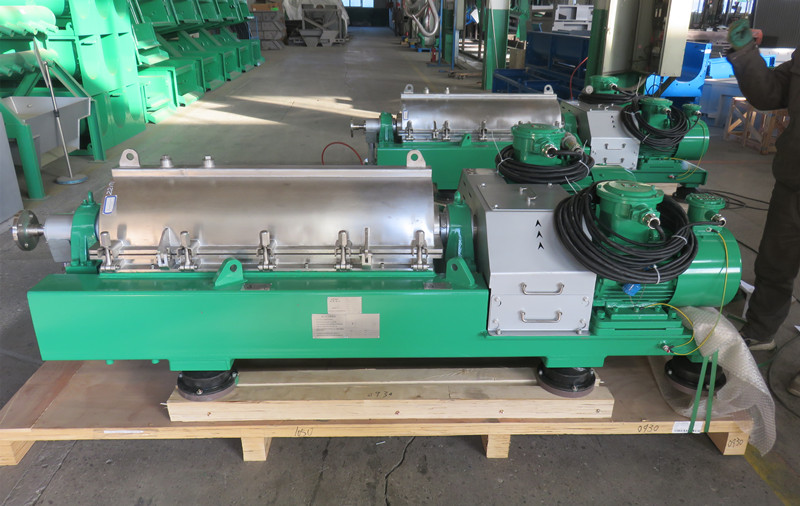

Decanter Centrifuges Specialized in Sludge Dewatering Ready for Inspection

This week, GN Separation completed the assembly of four GNLW224 decanter centrifuges along with their corresponding polymer dosing units at its manufacturing facility. The equipment is scheduled for final inspection and acceptance testing by an overseas client next week. Continue reading

Introduction of the main characteristics of a decanter centrifuge

The decanter centrifuge is one of the separation machines. Compared with other centrifuges, it has its special features, and these special features also enable the centrifuge to better improve the efficiency of the work, so it It can bring convenience to the entire project process.

Regarding its special features, there are mainly the following points:

1. The work of the decanter centrifuge is mainly relying on centrifugal force, which drives the entire centrifuge to perform high-speed work, so that it can exert its effects. It has a relatively strong effect on the dehydration of solids. During the entire dehydration process, manual operations are not required, and fully automated operations can be realized only by controlling it to a certain extent.

- When we are using the decanter centrifuge, it is very necessary to protect and maintain it. The maintenance requirements of the decanter centrifuge are relatively ordinary. Only simple care is required at ordinary times. It requires frequent and complicated maintenance.

- The decanter centrifugelooks like a compact machine in appearance, it occupies a relatively small space, and the entire distribution equipment is relatively simple. During the use of the decanter centrifuge, as long as it is routinely protected and maintained, its service life will be very long.

GN high-end CNC lathes, CNC centers, and CNC gantry milling machines can better ensure the machining accuracy of centrifuge parts. In terms of the dynamic balance of the decanter centrifuge, in addition to the ordinary low and medium speed dynamic balance, GN also applies a high speed dynamic balance process, which can dynamically balance the centrifuge screw and bowl at the actual working speed of the centrifuge. In terms of market applications, GN decanter centrifuges are widely used in the industry, and the products are exported to more than 60 countries and regions in the world, and have won high praise from customers.

What are the frequently asked questions about decanter centrifuge?

Decanter centrifuge is a kind of centrifuge. It is a kind of mud-water mixture that enters the drum through the feed pipe and the screw discharge port. Under the action of the centrifugal force generated by the high-speed rotation of the main engine, the solid particles with larger specific gravity are deposited on the inner wall of the drum, and the spiral blades moving relative to the drum successively scrape the solid particles deposited on the inner wall of the drum and push them out. The slag outlet, the separated clear liquid flows out of the drum machine through the opening of the weir plate.

1. What are the main components of the screw conveyor in the decanter centrifuge?

The screw conveyor of the Decanter centrifuge contains two parts: the drum and the screw, and the screw includes the cylinder and the pusher blade. On the cylinder, there is a feed end and a clear liquid outlet end, which are used to feed materials and flow out the clear liquid after separation.

2. Why can the Decanter centrifuge be used in petrochemical and waste treatment?

Because the decanter centrfuge has the characteristics of compact structure, low energy consumption, strong production capacity, and good adaptability to materials. And with the continuous development of science and technology, the centrifuge has been greatly improved and advanced in terms of structure, performance and technical parameters, and its separation effect has also been improved, so it is used in petrochemical and The treatment of the three wastes is very suitable.

3. Can the decanter centrifuge be used as the main engine of sludge dewatering?

If it is used for sludge dewatering, it is very suitable, and if it has a large aspect ratio and a fully enclosed operation is selected, then it can have a good use effect, because its It has advantages that other sludge dewatering equipment does not have.

4. What is the process of desilting using a decanter centrifuge in a sewage treatment plant?

In the wastewater treatment plant, in the treatment of activated sludge, the whole process of using a decanter centrifuge to desludge is to drive the high-speed rotation of the sludge through a high-speed rotating drum, and then generate centrifugal force to make the sludge The sedimentation of the solid particles accelerates and concentrates on the wall of the drum. Then, through the spiral, the formed mud cake is scraped to the small end of the rotating drum, so that it can be discharged, thereby completing the desliming work.

5. What is the main use of the decanter centrifuge? In addition, what are the unloading conditions of the decanter centrifuge?

Decanter centrifuge is mainly used to remove impurities and suspended solids in the liquid to achieve the role of purification. The general decanter centrifuge, its discharge conditions, mainly including cone angle and bowl speed.

Bearing Replacement Method for Decanter Centrifuge

During operation, a Decanter centrifuge runs at high rotational speeds, which places stringent demands on its bearings. Proper bearing maintenance and replacement are crucial to ensure smooth operation, prevent damage, and extend service life of the Decanter centrifuge.

When the drum bearings show signs of wear or malfunction and require replacement, it is essential to follow the correct procedure. The following steps outline the recommended bearing replacement method to ensure safe and reliable operation.

1. Preparation and Safety

Before starting, ensure the following:

Only qualified personnel should perform disassembly and assembly.

Use professional tools designed for bearing and centrifuge maintenance.

Disconnect the centrifuge from power and follow all lockout/tagout procedures.

Clean the working area and prepare lifting devices for the Decanter centrifuge if needed.

2. Disassembling the Small-End Bearing

Remove the Pressure Plate Bolts

Begin by loosening and removing the bolts from the pressure plate located on the main pulley end.

Extract the Pressure Plate

Use jack screws to evenly push out the end pressure plate. Ensure that all screws are loaded evenly to avoid skewing or deformation.

Remove the Pulley

Using a three-jaw puller, grip the pulley and pull it out carefully.

Mark Components for Reassembly

Clearly mark the relative positions of all components (keys, sleeves, seals, etc.) to ensure correct reinstallation later.

Remove Associated Components

Sequentially disassemble the flat key, taper-end screw, bearing seat sealing ring, and O-ring.

Extract the Bearing Assembly

Place a supporting pad on the bearing end face of the bowl shaft. Then, using a puller tripod, simultaneously remove the bearing sleeve, bearing sleeve gland, bearing, and shaft sleeve as a single unit.

3. Disassembling the Big-End Bearing

The process for the big-end bearing is similar but involves additional components:

Remove the Flange Bolts

Loosen and remove the flange bolts, then take out the differential and spline shaft.

Disassemble the Shaft End Pressure Plate

Remove the bolts from the shaft end pressure plate and use jack screws to push it out evenly. Keep the applied force balanced to avoid tilting.

Remove the Bearing Assembly

Place a pad on the shaft end face, then use a three-jaw puller to remove the connecting flange, bearing seat sealing ring, and flat key.

Extract Bearing Components

As with the small end, use a tripod puller to remove the bearing sleeve, bearing sleeve gland, bearing, and shaft sleeve together.

Make clear alignment marks on the bearing sleeve for accurate reassembly.

4. Key Notes for Reassembly

Ensure all parts are thoroughly cleaned and inspected for wear or damage before reinstallation.

Apply appropriate grease or lubricant to the bearings and seals according to manufacturer specifications.

Install the components in the reverse order of disassembly, aligning all marks made earlier.

After assembly, perform a manual rotation check to confirm smooth movement before restarting the centrifuge.

5. Summary

Although the replacement procedures for the small and big end bearings are similar, careful attention to detail is essential throughout the process. Accurate marking, even force application, and the use of correct tools will ensure safe bearing replacement and help maintain the reliability and longevity of the Decanter centrifuge.

Cause analysis and introduction for the failure of decanter centrifuge

During the feeding process, if the speed of the Decanter centrifuge‘s bowl is too high, it is very easy to cause uneven dispersion of the material, which directly causes the decanter centrifuge to vibrate, so when feeding material, we need to pay attention to this aspect. Continue reading

Principle and Function of Three-Phase Decanter Centrifuge

A horizontal spiral sedimentation centrifuge, commonly known as a decanter centrifuge, is an efficient piece of centrifugal separation equipment designed for continuous solid-liquid or liquid-liquid-solid separation. Based on structure and function, decanter centrifuges can be divided into horizontal spiral filter centrifuges and horizontal spiral sedimentation centrifuges. Continue reading

Hydrovac Slurry Separation System for America Client

In modern construction and utility installation projects—such as hydrovac excavation and horizontal directional drilling (HDD)—efficiently managing slurry waste is essential for both operational productivity and environmental responsibility. GN Separation specializes in the design and manufacture of advanced waste management systems engineered specifically for hydrovac slurry and directional drill mud treatment. Continue reading

Separation Function and Operation of the Decanter Centrifuge

The decanter centrifuge performs centrifugal separation on two- or three-phase liquid-solid heterogeneous mixtures with different densities. During operation, the main motor drives the two pulleys simultaneously, which in turn drive the bowl and the helical screw through a gear or cycloidal pin-wheel differential. This ensures a fixed relative differential speed between the bowl and the screw, allowing the materials to be separated efficiently at high speed. Continue reading

GNLW364-VFD Sludge Dewatering Centrifue for Overseas Environmental Company

GN Separation has successfully completed factory testing of two GNLW364-VFD decanter centrifuges, which are now en route to an overseas environmental company for use in municipal sludge dewatering projects. Continue reading