When the decanter centrifuge operates, the high-speed rotation of its drum generates a strong centrifugal force. This force drives solid particles—denser than the liquid phase—toward the inner wall of the drum, forming a solid layer (also known as the solid ring layer due to its annular shape). The liquid, having lower density and subject to less centrifugal force, remains inside the solid layer, forming the liquid ring layer.

Because the screw conveyor and the drum rotate at different speeds, a relative motion (differential speed) is created between them. This differential allows the screw to slowly convey the separated solids along the solid ring layer toward the conical end of the drum, where they pass through a drying zone. The solids are then discharged through outlets distributed around the periphery of the drum. Meanwhile, the clarified liquid from the liquid ring layer overflows through the weir openings and exits the drum by gravity, completing the separation process.

- Operation Management of decanter centrifuge

In this application, the decanter centrifuge is used in a blast furnace gas washing water sludge treatment system. Due to the wide variation in recovered water quality, abrasive sludge particles, and numerous external uncertainties, the system experiences severe equipment wear and complex operational challenges. Additionally, the treatment system involves various types of equipment and interconnected processes, demanding a high level of skill from operating personnel.

To ensure reliable performance, maintain the stability of each treatment stage, and maximize equipment effectiveness, it is essential to implement robust daily operation management practices and establish a well-defined set of management procedures.

- Separation Principle of the decanter centrifuge

The decanter centrifuge operates on the principle of centrifugal sedimentation to separate suspended solids from liquids. The solid phase is continuously pushed by the screw conveyor toward the small end of the drum, where it is discharged through the slag outlet. Meanwhile, the clarified liquid phase overflows through the outlet at the large end of the drum. This continuous process achieves uninterrupted solid-liquid separation.

- Liquid Separation Features of the Decanter Centrifuge

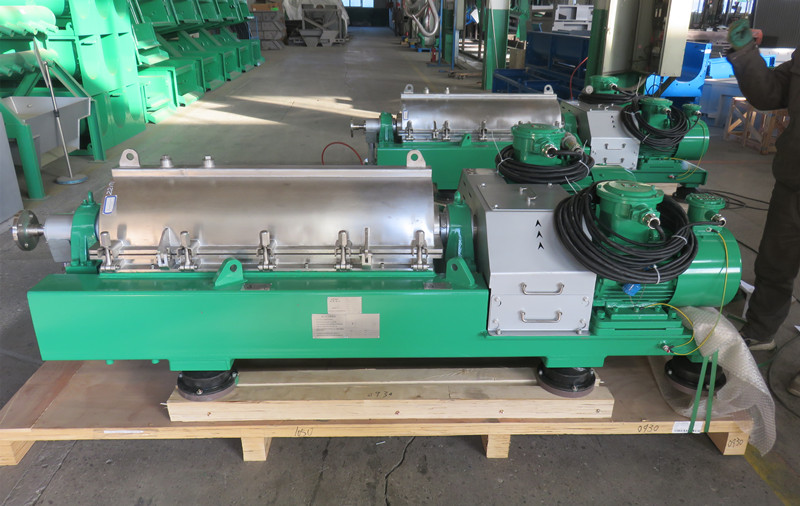

High-precision differential system: Equipped with an involute planetary gear differential, offering a large transmission ratio and high accuracy.

Dual overload protection: The entire machine is safeguarded with mechanical and electrical two-layer overload protection for safe operation.

Smooth motor operation: The main motor uses power-frequency speed regulation and is paired with a hydraulic coupling to ensure smooth performance.

Corrosion-resistant materials: All components in contact with the process material are made of high-grade stainless steel, providing excellent corrosion resistance.

Compact frame structure: The centrifuge features an integrated frame design that is safe, easy to hoist, and occupies minimal floor space.

Explosion-proof and sealed electrical system: Both power-frequency and variable-frequency electrical components meet explosion-proof standards, and the control box has superior sealing for enhanced safety and durability.