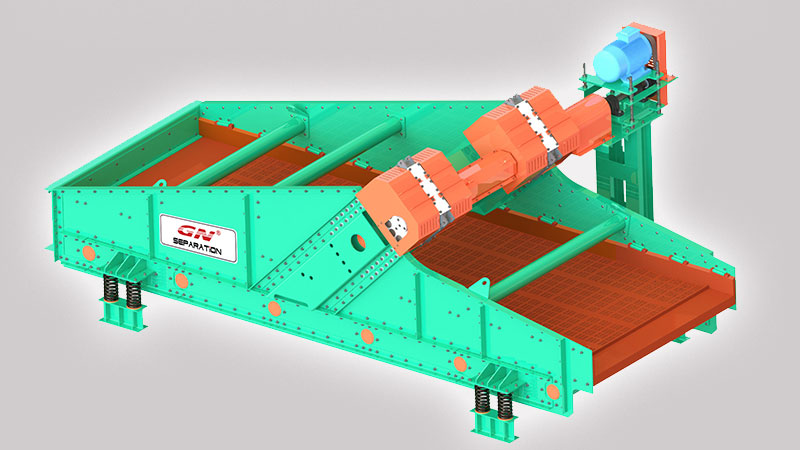

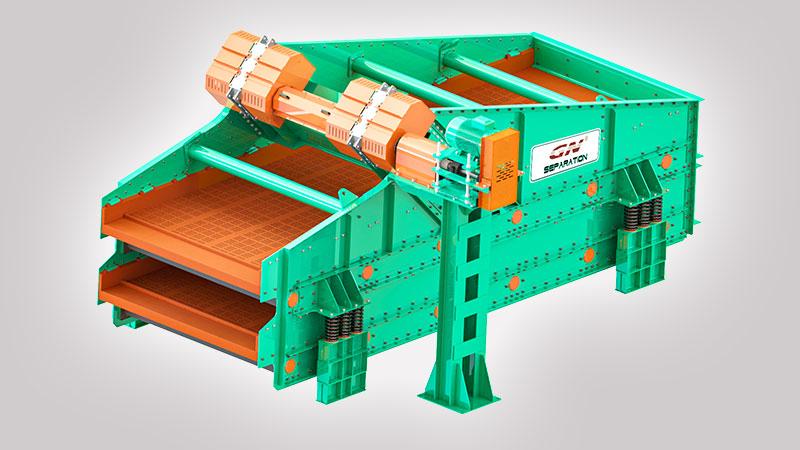

GN has developed a large linear vibrating screen for our iron ore clients. It is a large vibrating screen is a mechanical tool used to separate solid particles of different sizes by utilizing the principle of vibration. These screens are commonly used in industries such as mining, metallurgy, coal, construction, and chemical processing. The primary purpose of a large vibrating screen is to separate materials into various sizes for further processing or to remove impurities. Large vibrating screens use a vibration mechanism to induce motion in the screen deck. This mechanism is often an eccentric shaft with counterweights or unbalanced motors. The vibration helps to convey the material along the screen and aids in the separation process. Large vibrating screens may have multiple screen decks stacked on top of each other. This allows for the separation of material into different fractions in a single pass. The screen surface is the area where the material separation takes place. It is typically made of durable materials such as steel or polyurethane. The screen surface may have different opening sizes or patterns to allow for the classification of materials based on size. The drive unit is responsible for generating the vibratory motion. It can be an electric motor or a hydraulic drive system, depending on the design and application. A robust support structure is essential to provide stability and support for the vibrating screen. This structure must be able to withstand the dynamic forces generated during operation. The angle of the screen deck is adjustable and influences the material’s movement on the screen. The angle is typically set to optimize the screening process for specific applications. Material is fed onto the vibrating screen at one end, and the separated fractions are discharged at the other end. The design of the feed and discharge ports can impact the efficiency of the screening process. The screening media is the material used on the screen surface to facilitate the separation process. Common types include woven wire mesh, polyurethane panels, or perforated plates. Large vibrating screens are used in various industries for applications such as scalping, dewatering, classifying, and sizing bulk materials. The specific design and features of a vibrating screen depend on the material characteristics, required throughput, and the operational conditions of the process. GN we have three different types of screens. Large linear vibrating screen, large banana vibrating screen, and large flip-flow vibrating screen. Our large screens assist mining companies with their projects and success.