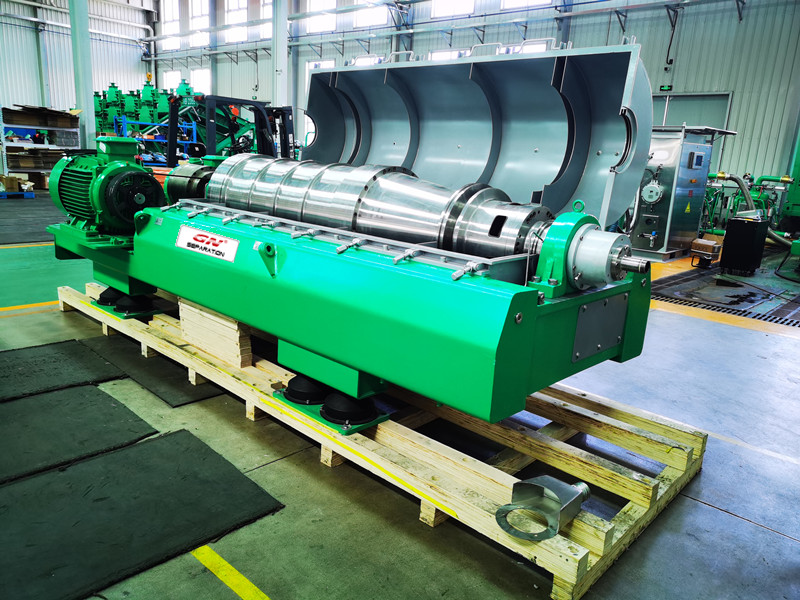

Just like people, objects require regular maintenance, especially precision instruments that demand meticulous care. Proper maintenance of a decanter centrifuge not only improves its performance but can also extend its service life by three to five years. Experts emphasize that those responsible for maintaining decanter centrifuges must pay close attention to the following important aspects to ensure their longevity:

Daily Maintenance

The primary goal of daily maintenance is to prevent contamination, dust, and oil residue inside the decanter centrifuge chamber. Before and after each use, it is essential to clean any oil, water vapor, sample leakage, and debris from the chamber and the surface of the centrifuge with a clean, white silk cloth. Avoid leaving the chamber door open when the centrifuge is not in use to prevent contamination.

The door’s sealing rubber ring must remain in good condition. After prolonged use, apply vacuum sealing grease to the rubber ring. If the sealing ring shows signs of aging, cracking, or loss of elasticity, replace it immediately to maintain proper sealing. Additionally, ensure that the switches, knobs, and fault indicators on the control panel are in good working condition. If any abnormalities or malfunctions are detected during operation, shut down the machine immediately for maintenance.

Annual Overhaul

The internal systems of the decanter centrifuge should undergo a thorough inspection and maintenance at least once a year. Pay special attention to any suspicious parts and clean any accumulated dirt or dust, particularly in the filter and internal components. If the centrifuge will not be used for an extended period, it is recommended to periodically power it on to activate the oil circulation and refrigeration systems, ensuring that the internal pipelines remain clear and functional.

Drive System Maintenance

The drive system is the core of the decanter centrifuge, and any issues in its components can disrupt the machine’s operation. Key components such as the high-speed motor, variable speed gear, rotating bearings, and sliding bearings must be closely monitored. Any abnormal noise, vibration, or irregularity in these parts requires immediate attention and repair to maintain the centrifuge’s smooth and reliable performance.