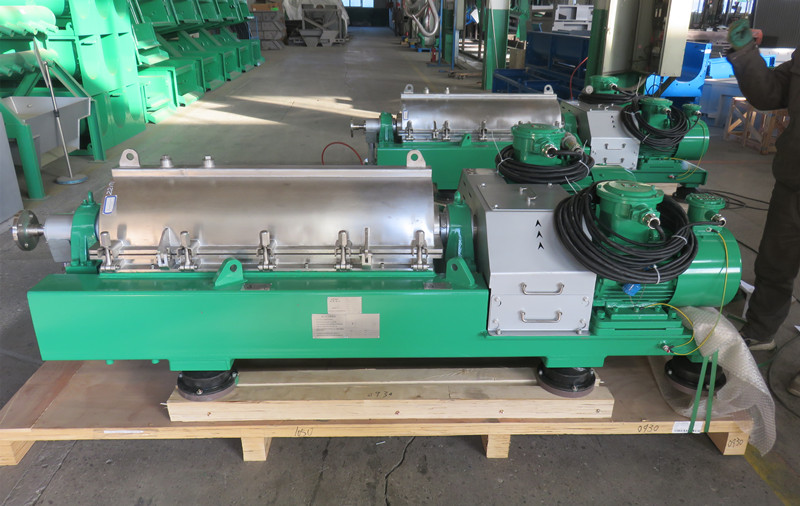

A decanter centrifuge is a powerful piece of equipment used to separate mixtures of two or three components (typically liquid-solid or liquid-liquid-solid) based on differences in density. To ensure safe, efficient, and effective operation, the following steps and precautions should be followed:

1. Principle of Operation

The decanter centrifuge operates on the principle of centrifugal sedimentation. During operation:

The main motor drives two pulleys, which in turn rotate the bowl (drum) and the scroll (screw conveyor).

The rotation is managed through a differential gearbox (cycloidal or planetary) that maintains a constant differential speed between the bowl and scroll.

This differential allows the screw to convey solids toward the discharge while the bowl spins at high speed to separate solids from liquids.

2. Importance of Balance

To achieve optimal separation and prevent equipment damage, proper balance is critical:

The decanter centrifuge bowl, rotor, and all components must be precisely balanced before operation.

Centrifuge tubes and their contents must be balanced by weight according to the manufacturer’s specifications. For ultracentrifuges, the weight difference between paired tubes should not exceed 0.1 g.

If using centrifuge tube sleeves, ensure that the sleeves are balanced and not interchanged between different centrifuge models.

3. Loading and Setup

Before starting the centrifuge:

Ensure even and symmetrical loading of the centrifuge tubes into the rotor or drum.

Close and securely fasten the centrifuge cover.

Turn on the power supply, and set the operating parameters including:

Bowl speed (RPM)

Differential speed

Centrifugation time

(If applicable) Temperature, vacuum level, and feed rate

4. During Operation

Monitor the unit for vibration, noise, or imbalance, and ensure smooth operation.

Most modern decanter centrifuges are equipped with automatic control systems that manage speed, temperature, timing, and safety interlocks.

5. Stopping and Unloading

As the set separation time approaches, gradually reduce speed using the control panel or allow the automatic system to initiate deceleration.

Wait for the drum to come to a complete stop naturally.

Open the cover and carefully remove the centrifuge tubes or inspect the discharge outlets.

Turn off the power and unplug the unit if not in continuous operation.

6. Cleaning and Maintenance

After each use:

Clean the bowl, scroll, centrifuge chamber, tubes, and sleeves thoroughly to prevent residue buildup.

Inspect wear-prone components such as seals, bearings, and nozzles regularly.

Ensure no foreign objects or residue are left inside the drum to avoid imbalance in future operations.

7. Safety Precautions

Never open the cover while the centrifuge is running.

Avoid operating the centrifuge if it is visibly unbalanced or damaged.

Always refer to the manufacturer’s user manual for specific tolerances and maintenance intervals.

By following these guidelines, you can ensure the decanter centrifuge operates safely, maintains long-term performance, and delivers reliable separation results.