Proper handling and maintenance of decanter centrifuges are essential to ensure safety and efficiency. Uncontrolled centrifugal force can cause significant damage, so careful attention to operational procedures is critical. Although decanter centrifuges are straightforward to use, adhering to proper guidelines can prevent malfunctions and costly delays.

1. Pre-Cooling and Maintenance:

- Always keep the centrifuge cover closed during pre-cooling.

- After centrifugation, place the rotor upside down on the test bench and wipe off any residual water in the chamber.

- Leave the decanter centrifuge cover open after use to allow ventilation.

2. Handling the Rotor Cover:

- During pre-cooling, the rotor cover should be placed on the centrifuge platform or test bench, never left loosely attached to the rotor.

- If the rotor cover is not securely tightened and the centrifuge starts accidentally, it can be ejected and cause severe injury or damage.

3. Ensuring Proper Seal:

- After tightening the rotor cover, check for gaps between the rotor and the cover using your fingers.

- If a gap is detected, unscrew and retighten until there is a complete, secure seal.

4. Monitoring During Operation:

- Operators must remain in the centrifuge room during operation.

- If an abnormal situation occurs, do not turn off the power directly. Instead, press the STOP

- Always complete the centrifuge usage record before initiating pre-cooling.

5. Using Appropriate Centrifuge Tubes:

- Avoid using low-quality, aged, deformed, or cracked centrifuge tubes, as they can fail under high-speed operation.

6. Routine Inspections:

- During holidays or overnight periods, conduct routine safety inspections before leaving the centrifuge unattended.

7. Reporting Malfunctions:

- If a machine failure or part damage occurs, contact the manufacturer immediatelyfor professional assistance.

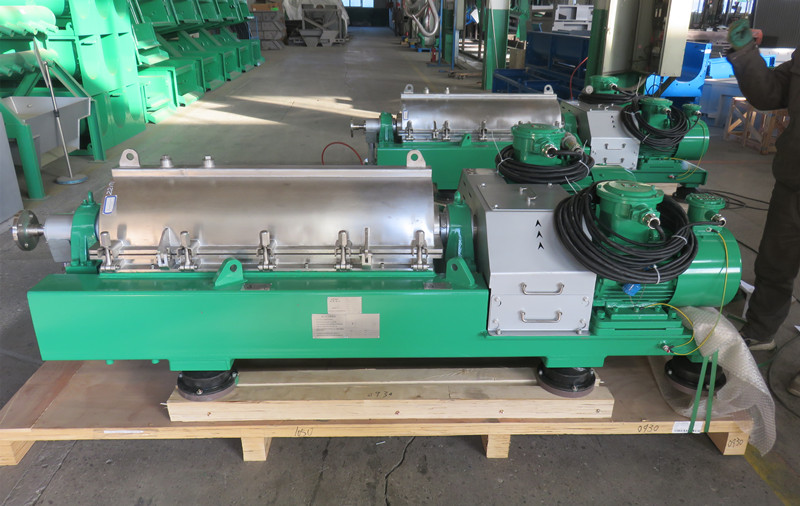

GN Separation is a leading manufacturer of decanter centrifuge. With strong technical expertise, advanced processing facility, comprehensive testing methods, and stringent internal management standards, GN separation stands as a backbone enterprise in the decanter centrifuge industry in China. The company boasts modern facilities, robust scientific research capabilities, and generalized processing expertise, positioning it as a key player in both of the domestic and international markets.