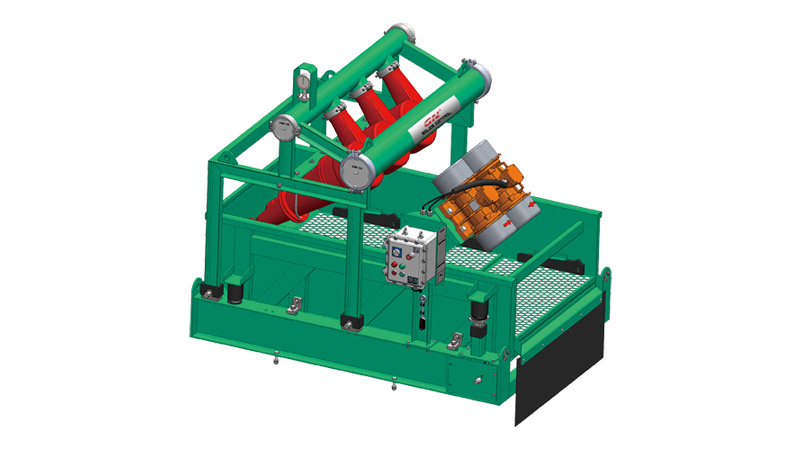

A desander is a piece of equipment used in the oil and gas industry to remove sand and other solid particles from drilling mud. Drilling mud, also known as drilling fluid, is a crucial component in drilling operations as it helps to cool and lubricate the drill bit, carry cuttings to the surface, and provide support to the wellbore walls. At GN we have two different types of applications for our desander. First application is for oil gas drilling, CBM drilling mud solids control. Second is desander system with mud tank is for construction operation for no dig, bored pile drilling desander for bentonite recycling. The desander is part of a larger system of equipment designed to clean and maintain the drilling mud. GN desander is the second class and the third class solid control equipment to treat the drilling fluid. According to the size of the cone diameter, it is divided into Desander and desilter. Usually the cone diameter is more than 6″is called desander, and used as the second-control equipment in drilling operation. We commonly used 8 “and 10” cones desander to separate solid-phase particle size 47-76μm in the drilling fluids. Drilling mud containing solids and sand is fed into the desander through an inlet. The heart of the desander is a set of hydrocyclones, which are essentially conical-shaped vessels. These hydrocyclones create a swirling flow pattern, causing the heavier solids (including sand) to move towards the outer wall. As the drilling mud moves through the hydrocyclone, centrifugal force causes the heavier particles to settle at the bottom and be directed out of the desander, leaving the cleaner mud to continue its journey. The separated solids, which settle at the bottom of the hydrocyclone, form the underflow and are typically removed for further processing or disposal. The cleaner mud, referred to as the overflow, exits the hydrocyclone and is directed back into the drilling mud system. Desanders are effective in removing coarse particles from the drilling mud, preventing excessive wear on drilling equipment and maintaining the integrity of the wellbore. In some cases, desanders are used in conjunction with desilters, which are designed to remove smaller particles.It’s worth noting that the design and capacity of desanders can vary depending on the specific drilling operation, the type of drilling mud being used, and the characteristics of the solids in the mud. Efficient solids control is essential for successful and safe drilling operations in the oil and gas industry. Our desanders work with multiple equipments and are versatile to work in different types of operations.