Clean water is becoming an increasingly valuable resource, which is why the importance of urban sewage and drinking water treatment continues to grow worldwide. Sludge generated during water and wastewater treatment must be separated and reduced as efficiently as possible to minimize disposal costs and environmental impact.

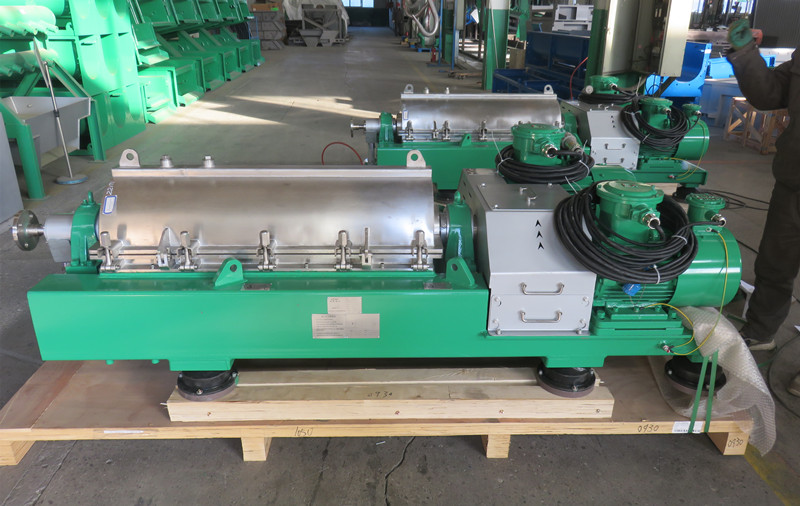

Today, the industrial decanter centrifuge is widely recognized as one of the most advanced and effective technologies for sludge thickening and dewatering. It offers significant advantages in terms of high efficiency, energy savings, continuous operation, and economical performance, making it a preferred solution for modern sewage treatment plants.

GN Separation has more than 15 years of experience in sewage sludge treatment and a deep understanding of the specific requirements of municipal wastewater treatment plants and the water industry. Established in 2007, the GN brand has supplied separation equipment to customers in more than 70 countries worldwide, with over 70% of products exported to international markets.

To better support global customers, GN has established branches in Houston, USA, and Moscow, Russia, providing localized technical support and after-sales service.

GN sludge dewatering decanter centrifuges are specifically developed to meet the special operating conditions of sewage treatment plants, including continuous operation, variable sludge properties, and strict environmental standards.

The primary objective of sludge dewatering is to minimize sludge volume. Even a small increase in dry solids content can significantly reduce sludge transportation and disposal costs. In practice, every 1% increase in dry solids content can lead to substantial savings in handling and landfill expenses.

By efficiently compacting sludge, GN decanter centrifuges help concentrate the dry solids content within a narrow and stable range, resulting in:

Reduced sludge volume

Lower transportation and disposal costs

Improved downstream treatment efficiency

GN decanter centrifuges are also highly effective in polymer-assisted sludge thickening and dewatering processes. When used together with polymer-based flocculants, the decanter centrifuge can achieve excellent separation results, allowing most of the polymer-bound solids to be efficiently removed from the liquid phase.

Optimized centrifuge design and adjustable operating parameters help:

Improve floc stability

Reduce polymer consumption

Achieve higher dry solids content

Sludge is generated not only in municipal sewage treatment but also in drinking water treatment plants. In both applications, GN decanter centrifuges play a key role in:

Increasing sludge dry solids content

Reducing sludge transportation and landfill costs

Lowering polymer usage

Improving overall plant operating efficiency

With proven technology, extensive industry experience, and a global support network, GN decanter centrifuges provide a reliable and efficient solution for sewage sludge thickening and dewatering. They help treatment plants reduce operating costs, improve environmental performance, and meet the growing demand for sustainable water and wastewater management.