News for GN’s customers: GN Separation would like to Invite you to join the China Coal & Mining Expo 2023 during 25-28 Oct 2023.

Organized by China Coal Industry Association, China Coal Energy Group Co., Ltd., China Coal Industry International Technical Consulting Co., Ltd. Huiming Exhibition Co., Ltd. hosted the 20th China International Coal Mining Technology Exchange and Equipment Exhibition (China Coal & Mining Expo 2023) will be held at the China International Exhibition Center (New Pavilion) in Beijing on October 25-28, 2023. The theme of the exhibition is “Smart leads the future, green shared development.” The exhibition focuses on new equipment, new technology and new products in China’s coal industry. The exhibition is expected to be more than 130,000 square meters in size, exhibitors close to 1,000, professional audience is expected to again surpass 120,000 visitors.

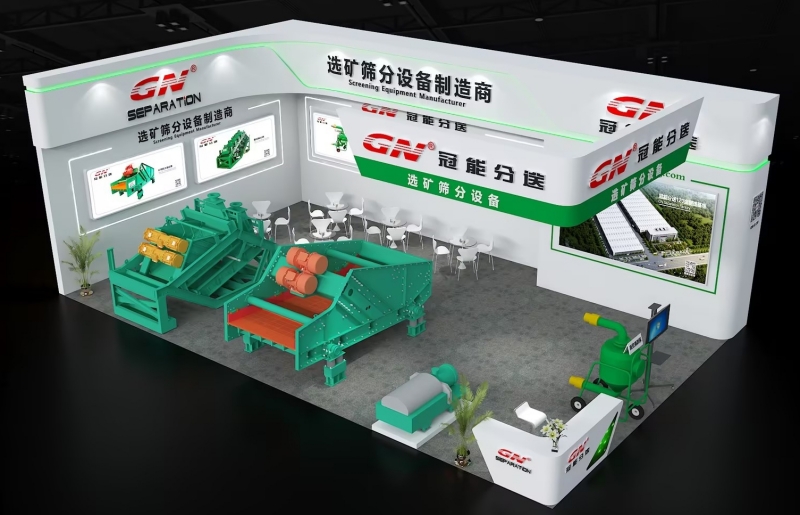

Our booth number is :E4106

Our exhibition equipment:

Stack vibrating screen, liner motion dewatering vibrating screen, Decanter centrifuge, Vacuum Pump

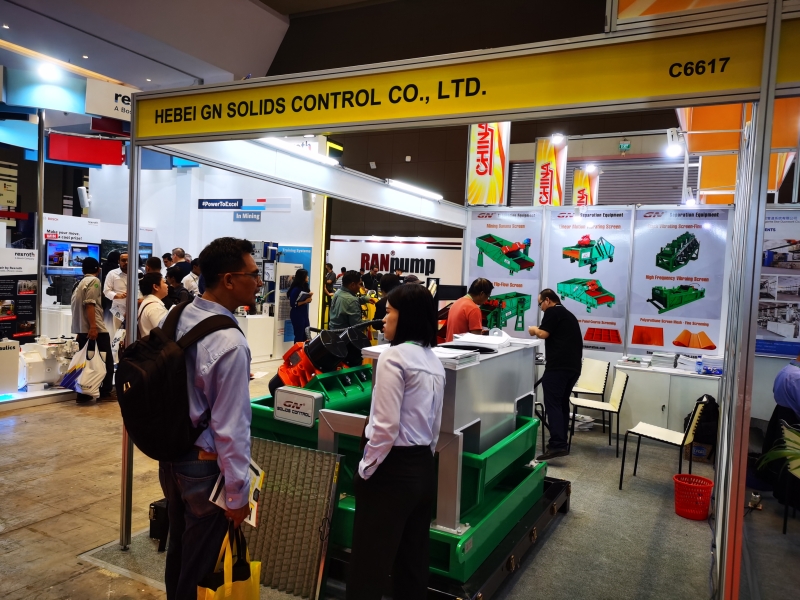

Hebei GN Separation Equipment Co., Ltd (GN Separation) is a wholly-owned subsidiary of GN Solid Control. The Mine Business Department of GN Separation is specially responsible for the development and manufacture of mining vibration screen equipment.

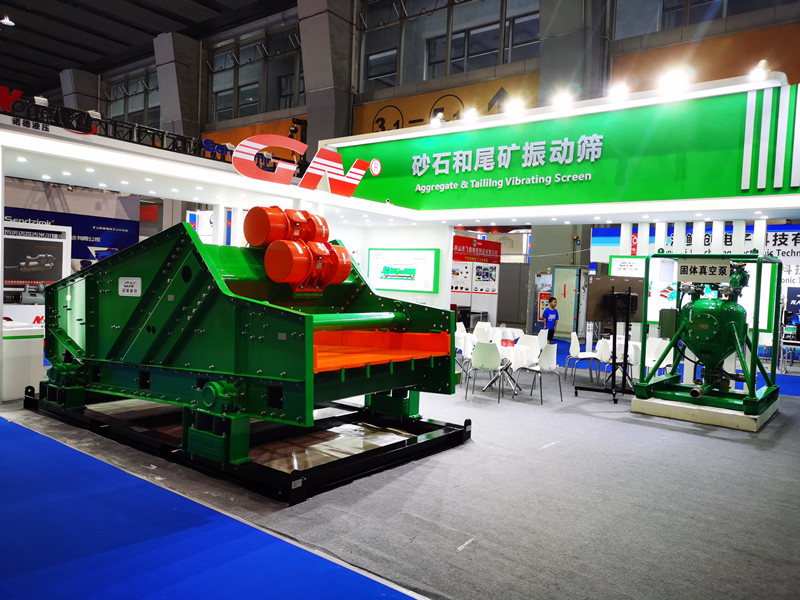

In addition to fine vibrating screen and medium vibrating screen, GN Separation has also developed large double-layer vibrating screen products. Including the following series:

1. Large double-layer linear vibrating screen

2. Large double-layer banana vibrating screen

3. Large double-layer flip flop vibrating scree

To make sure this series of mining vibrating screen will provide a reliable performance and the parts and components of all the equipment will run smoothly for a long term operation, our technical department, production department and quality control department have paid a lot of attention to the material selection, material preparation, every step of production and the inspection for this set of equipment in each step.