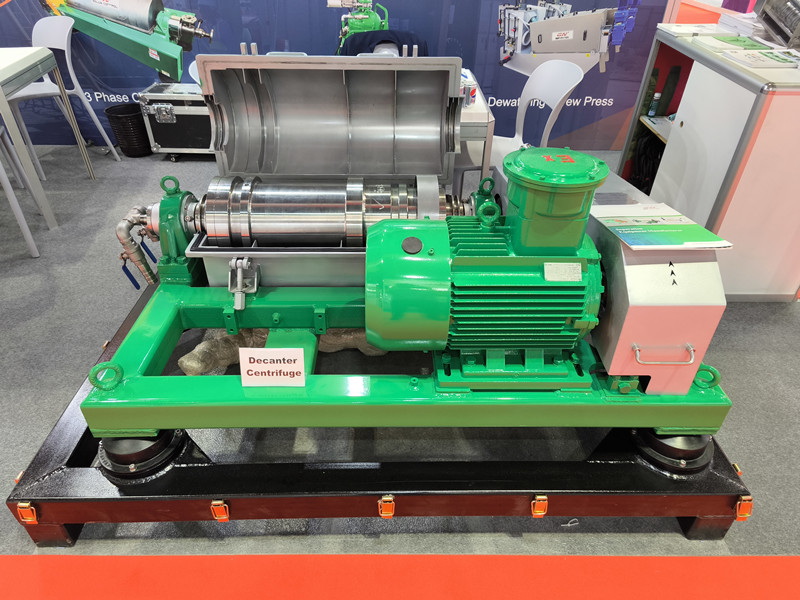

GN Company will participate in the upcoming CIPPE (China International Petroleum & Petrochemical Technology and Equipment Exhibition) and showcase its latest technological product, the second-generation three-phase decanter centrifuge.

As a renowned event in the global oil and gas industry, CIPPE attracts numerous companies from around the world to showcase their latest research and technological innovations in the field of petroleum and petrochemical technology and equipment.

GN Company‘s decision to exhibit its second-generation three-phase decanter centrifuge at this exhibition undoubtedly demonstrates its confidence in its technological prowess and product quality.

Exhibition Name: The 24th China International Petroleum & Petrochemical Technology and Equipment Exhibition

Exhibition Time: 25th-27th, March, 2024

GN Booth No.: E2168

The three-phase decanter centrifuge boasts a wide range of applications, capable of handling various types of materials. Its continuous working structure enables efficient and stable solid-liquid separation.

Furthermore, the centrifuge offers advantages such as high processing capacity, low cost, and ease of maintenance, making it an ideal choice for solid-liquid separation.

Notably, the three-phase decanter centrifuge is not limited to solid-liquid separation.

It also possesses the capability to separate two different-density liquids within the material, enabling solid-liquid-liquid three-phase separation.

Widely used in industries such as petroleum, chemicals, and pharmaceuticals, the performance stability and separation effectiveness of the three-phase decanter centrifuge directly impact the production efficiency and product quality of related industries.

GN Company‘s second-generation three-phase decanter centrifuge has undergone significant technological and performance enhancements, better meeting market demands.

For GN Company, participating in CIPPE is not only an opportunity to showcase its technological strength and product advantages but also an important platform for exchanging ideas, learning, and collaborating with peers. Through this exhibition, GN Company can gain a deeper understanding of industry trends and market demand changes, paving the way for its future development.