GN Separation is proud to announce that a new set of GNLW224 dewatering centrifuges, together with an integrated, intelligent polymer dosing system, is now fully assembled and ready for Factory Acceptance Test (FAT) for our overseas client. This package represents GN’s continuous commitment to providing high-efficiency, automated, and user-friendly dewatering solutions for global environmental and industrial applications.

Fig. 1 Horizontal decanter centrifuge

Smart Polymer Dosing System — Enhancing Dewatering Efficiency

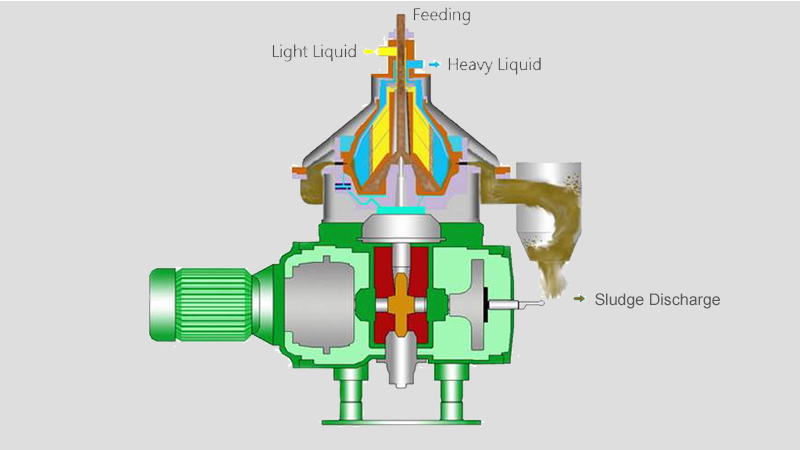

In any sludge dewatering process, the polymer dosing system plays a decisive role. Proper flocculant preparation and accurate dosing directly influence the formation of strong, stable flocs, which ultimately determine the separation performance of a decanter centrifuge. For this project, GN has supplied a fully automated, three-tank polymer preparation unit, equipped with precise dosage control and real-time adjustment features.

The intelligent dosing system works seamlessly with the GNLW224 centrifuge. By monitoring feed flow, sludge characteristics, and centrifuge load, the control logic automatically adjusts polymer concentration and dosing rate. This ensures optimal floc formation under varying operational conditions, helping the centrifuge achieve higher dryness, cleaner centrate, and lower polymer consumption. For end users, this means lower operational costs and more stable long-term results.

Fig. 2 Polymer dosing unit.

GNLW224 — Compact but Powerful Dewatering Centrifuge

The GNLW224 model is GN’s compact-size dewatering centrifuge widely used for municipal sludge, industrial wastewater, and small-scale treatment systems.

When paired with the intelligent dosing unit, the GNLW224 becomes a complete, plug-and-play dewatering package suitable for overseas installations where local commissioning resources may be limited.

Smooth Integration and Easy Operation

The entire system—including the centrifuge, dosing unit, pumps, and control cabinet—is pre-installed, wired, and tested on the skid before FAT. GN engineers simulate on-site working conditions to verify mechanical operation, control logic, safety interlocks, and communication between the dosing system and centrifuge. This integrated design allows the end user to achieve quick installation, fast startup, and minimal operational tuning.

Ready for FAT and Global Delivery

With all mechanical and electrical checks completed, the equipment is now ready for the final FAT procedure with our overseas client. After FAT approval, the system will be packed and shipped, continuing GN’s mission of delivering reliable separation technology to partners worldwide.

GN Separation will keep advancing intelligent control, automation, and environmental technologies to support global customers with efficient and dependable dewatering solutions.