To ensure optimal performance and long-term reliability of a decanter centrifuge, operators must adhere to specific principles and operational guidelines. Neglecting these procedures or deviating from the recommended sequence can lead to inefficiencies, increased maintenance time, and costly operational setbacks—especially when dealing with high-viscosity or high-solid-content liquids. Continue reading

Category Archives: Decanter Centrifuge

Top 5 Common Centrifuge Problems and How to Fix Them

Centrifuges play a vital role in industrial processes such as wastewater treatment, palm oil processing, food production, and chemical separation. However, like any piece of complex machinery, they are vulnerable to wear, improper use, and lack of maintenance. Identifying and addressing common problems early is essential to avoid costly downtime and extend the machine’s lifespan. Here are the top five centrifuge problems and practical solutions.

Excessive Vibration

This is one of the most common and damaging issues. It may result from misaligned installation, solids buildup, or worn bearings. Machines should always be installed on level ground. Regular cleaning, bearing inspection, and dynamic balancing of rotating parts can greatly reduce vibration.

Poor Separation Performance

If your centrifuge is producing wet cake or unclear filtrate, the problem may be improper feed flow, worn internal components (like the scroll or bowl), or incorrect differential speed. Operators should routinely monitor performance and adjust parameters accordingly. Replacing worn parts can restore optimal efficiency.

Motor or Gearbox Overheating

Overheating is often caused by insufficient lubrication, blocked airflow, or operating under excessive load. Always use the correct type and amount of lubricant. Keep ventilation areas clear and check oil temperature and pressure during operation.

Unusual Noises

Grinding, knocking, or screeching sounds often indicate serious issues like damaged bearings or the presence of foreign objects. When unusual noise is detected, the machine should be shut down immediately and inspected thoroughly.

Frequent Shutdowns or System Alarms

This may stem from sensor malfunctions, electrical faults, or imbalanced loads. Check for software errors in the PLC, calibrate sensors, and verify the feed distribution to avoid unnecessary shutdowns.

Conclusion

Preventive maintenance is the key to stable performance. Weekly inspections, timely part replacements, and proper training for operators can dramatically reduce failure rates. At GN Separation, we provide reliable OEM centrifuge equipment, spare parts, and technical support to ensure your operations stay efficient and interruption-free

The Role of Decanter Centrifuges in Offshore Drilling Platforms

Why Drilling Mud Management is Crucial

In the demanding offshore drilling environment, managing drilling fluids and maintaining operational efficiency are paramount. One of the key pieces of equipment that ensure smooth operations is the decanter centrifuge, which plays a crucial role in separating solids and liquids from drilling mud, a vital task in offshore drilling platforms.

The Function of Decanter Centrifuges in Fluid Separation

Drilling mud is used to lubricate and cool the drill bit, as well as to lift cuttings to the surface. However, over time, this mud becomes contaminated with solid particles, which can impact drilling efficiency. Decanter centrifuges are designed to separate these solids from the drilling fluid, ensuring the mud remains clean and effective for reuse. This is critical for maintaining the proper viscosity of the drilling fluid, improving drilling performance, and minimizing costs.

Reliability in Harsh Offshore Environments

On offshore platforms, where space is limited and conditions are harsh, decanter centrifuges are engineered to operate reliably and efficiently. These machines are built to withstand the challenges of marine environments, including exposure to corrosive saltwater and extreme weather conditions. With their ability to operate continuously, they minimize downtime and ensure consistent performance, even under the toughest conditions.

Customization for Optimal Performance

One of the key advantages of using decanter centrifuges in offshore drilling is their customizability. Depending on the type of drilling mud and specific needs of the operation, the centrifuges can be adjusted for bowl speed, conveyor design, and other factors to optimize performance.

Conclusion: Essential Equipment for Offshore Drilling

In conclusion, decanter centrifuges are an essential part of offshore drilling platforms, offering reliable, efficient, and cost-effective solutions for fluid management. Their ability to handle the tough tasks of solid-liquid separation makes them indispensable in maintaining the productivity and safety of offshore drilling operations.

Decanter Centrifuge and Screw Press: Which is Better for Your Wastewater Treatment?

When it comes to separating solids from liquids in wastewater treatment, two common and highly efficient devices are the decanter centrifuge and the screw press. Both play crucial roles in industrial processes, but choosing the right one for your application depends on several factors, including the type of wastewater, the desired solids concentration, and operational costs. Let’s explore the differences between these two technologies to help you make an informed decision.

Decanter Centrifuge: High-Speed Separation

A decanter centrifuge uses high-speed rotational forces to separate solids from liquids. As wastewater enters the centrifuge, it is spun rapidly, causing the denser solids to accumulate on the outer edge, while the clarified liquid moves toward the center. This process is highly effective for separating fine, small particles, which is why decanter centrifuges are ideal for applications where high solid-liquid separation efficiency is required.

The primary advantage of a decanter centrifuge is its ability to handle a wide range of solid particle sizes and its speed. It can achieve very high G-forces, leading to quick separation and a high concentration of solids. Decanter centrifuges are well-suited for industries such as oil and gas, chemical processing, and sludge treatment, where the solid content is varied and requires precise separation. However, they tend to be more expensive in terms of initial investment and maintenance.

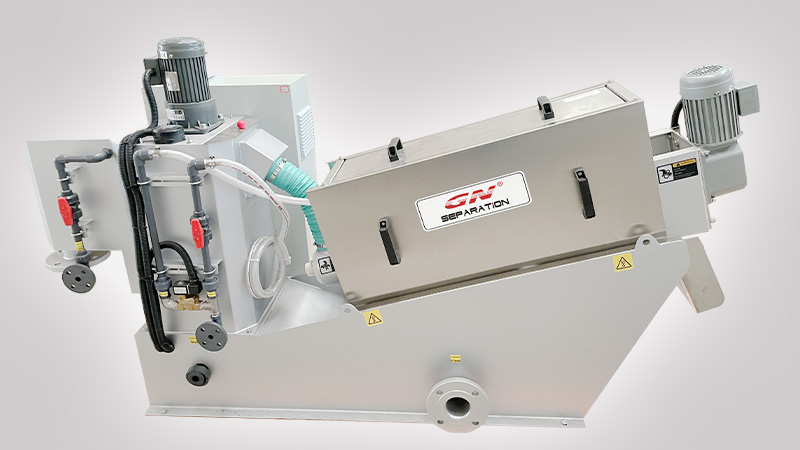

Screw Press: A Simpler, Cost-Effective Option

On the other hand, the screw press (also known as a screw press dewatering machine) offers a more cost-effective, low-maintenance solution for wastewater treatment. The screw press operates by gradually compressing the slurry between a rotating screw and a series of screens. As the material moves along the screw, the liquid is squeezed out, and the solid material is compacted and discharged.

Screw presses are often used in applications where high flow rates and lower operational costs are desired. They are particularly useful for handling larger particles and can handle sludges with higher solid content. Although screw presses do not achieve the high solid concentrations of decanter centrifuges, they still offer good dewatering efficiency for many wastewater treatment processes.

Which One is Right for You?

Choosing between a decanter centrifuge and a screw press depends on your specific requirements. If your wastewater has fine, small particles and requires high-speed, precise separation, a decanter centrifuge may be the better choice. However, if you need a cost-effective, low-maintenance solution for handling larger particles or reducing operational costs, a screw press could be more suitable.

Ultimately, the decision should be based on factors like the nature of the wastewater, the desired throughput, and budget constraints. Both technologies have their strengths, so understanding your unique needs is essential for making the best decision for your wastewater treatment process.

What Is the Difference Between a Filter Press and a Decanter Centrifuge?

Both filter presses and Decanter centrifuges are widely used in sludge dewatering and solid-liquid separation, but they differ significantly in their working principles, suitable applications, operational flexibility, and maintenance needs. The following outlines key distinctions and insights drawn from years of practical design experience and user feedback regarding decanter centrifuges:

1. Applicable Media: Not All Sludge Is Equal

Decanter centrifuges are not universally effective across all sludge types.

In particular, sludge with high inorganic content, such as fly ash, poses challenges.

Fly ash tends to adhere to the inner wall of the centrifuge drum, creating resistance and clogging the discharge system.

This issue has been observed in real-life cases, such as a municipal sewage plant in northern China, where the centrifuge failed to operate normally and had to be replaced—leading to significant operational loss.

Filter presses, on the other hand, are generally more suitable for inorganic-rich sludge, offering a more robust performance in handling fine, sticky, or high-density materials like fly ash.

2. Feed Control and Process Stability

Offer automated control capabilities, such as adjusting torque and scroll speed in response to variations in feed concentration.

However, these adjustments often still require manual calibration and monitoring.

Changes in feed consistency can affect performance, potentially leading to reduced dewatering efficiency or torque overload.

Filter presses:

Typically operate in batch mode, making them less sensitive to feed fluctuations.

However, they often require longer cycle times and manual intervention for unloading and cleaning.

3. Solid Recovery Rate and Chemical Usage

Decanter centrifuges generally achieve a high solid recovery rate:

This makes them ideal where continuous processing and automation are priorities.

However, not all low-recovery-rate applications are unsuitable—recovered filtrate can be recycled to the head of the treatment process for further separation.

Chemical dosage:

One point of contention is the amount of polymer (e.g., PAM) required.

In a 150,000 m³/day municipal treatment plant using a decanter centrifuge, the measured PAM consumption was approximately 1.7–2.0 kg per ton of dry sludge, which is considered efficient.

In contrast, filter presses in some cases consume up to 20 kg per ton of dry sludge, though this figure can vary widely depending on sludge composition and filtration efficiency.

Structure and Working Principle of the Decanter Centrifuge

The Decanter Centrifuge is an advanced separation device known for its low energy consumption, stable performance, and effective solid-liquid separation. It is widely used across various industries including chemical processing, food production, salt refining, mining, and pharmaceuticals. The decanter centrifuge is capable of separating a wide range of materials. Due to its versatility and proven application success, it is advisable to consult with technical experts when selecting a model to ensure the best match for specific processing needs. Continue reading

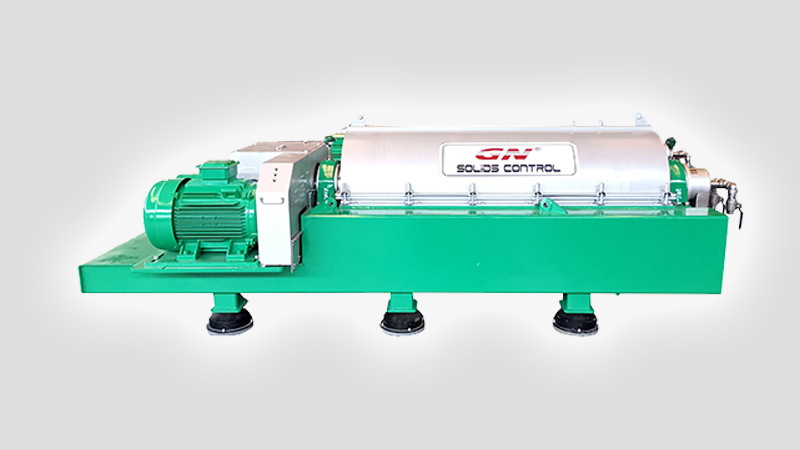

GN Separation Decanter Centrifuge: A Comprehensive Solution for Solid-Liquid Separation

GN Separation Decanter Centrifuge is a high-performance centrifugal separation machine designed to meet the complex requirements of solid-liquid separation. Known for its efficiency in separating fine, soft materials, this decanter centrifuge is ideal for applications where traditional separation methods may fall short due to challenging material properties.

Superior Design for Enhanced Separation

GN Separation Decanter Centrifuge features the Y-series design, which includes a beach angle of 15 degrees. This feature optimizes the separation process, ensuring that the clarified, lightweight liquid phase is gravity-discharged on the liquid side, while the heavier liquid phase exits the decanter together with the solid particles. This dual-phase separation ensures that both the liquid phase is clear and the solid phase is dry, meeting the comprehensive needs of industries that require high-quality separation results.

Versatile Applications

One of the most remarkable qualities of the Y-series decanter centrifuge is its versatility. It is particularly effective in separating fine and soft materials, which are often difficult to treat using other methods. The centrifuge excels in handling materials with small particle sizes, minimal density differences between solids and liquids, high viscosity, and low concentrations. These properties make it suitable for a wide range of applications across various industries.

Some of the most common uses of the GN Separation Decanter include:

Biological Pulp Separation: Essential for industries dealing with complex biological materials.

Yeast Solution and Protein Recovery: Vital for the food and beverage sector, especially in fermentation processes.

Recovery of Plant Starch and Juice By-products: Key for industries in the production of plant-based materials like soybean milk and grape juice.

Distiller’s Grains Liquid Recovery: Helps in extracting useful by-products from distillation processes.

Wastewater Treatment: Effective for separating low concentration activated sludge in water treatment plants.

Oil Refining and Saponification: Assists in the recovery of valuable components during the oil refining process.

Efficient Separation for Better Results

GN Separation Decanter Centrifuge is designed to offer a higher level of performance than conventional separation techniques, especially when dealing with difficult-to-separate materials. Its ability to handle materials with challenging properties, such as small density differences or high viscosity, makes it a highly valuable tool in industries like biotechnology, food production, wastewater treatment, and more.

In conclusion, GN Separation Decanter Centrifuge represents a highly efficient and reliable solution for industries that require high-quality solid-liquid separation. Whether it’s recovering proteins from yeast solutions or treating wastewater, this decanter centrifuge offers excellent performance, making it an indispensable part of modern industrial processes.

GN Module Hydrovac Slurry Dewatering System for Overseas Client

GN Separation have recently engineered and delivered a modular hydrovac slurry dewatering system for an international client, offering a high-efficiency, reliable solution for treating construction slurry, drilling mud, and industrial wastewater. This advanced system integrates five key modules—coarse screening, fine screening, desanding & desilting, centrifugation, and chemical dosing—to ensure effective solid-liquid separation and full environmental compliance. Continue reading

Enhancing Efficiency with GN T Series Decanter Centrifuge for Dewatering and Thickening

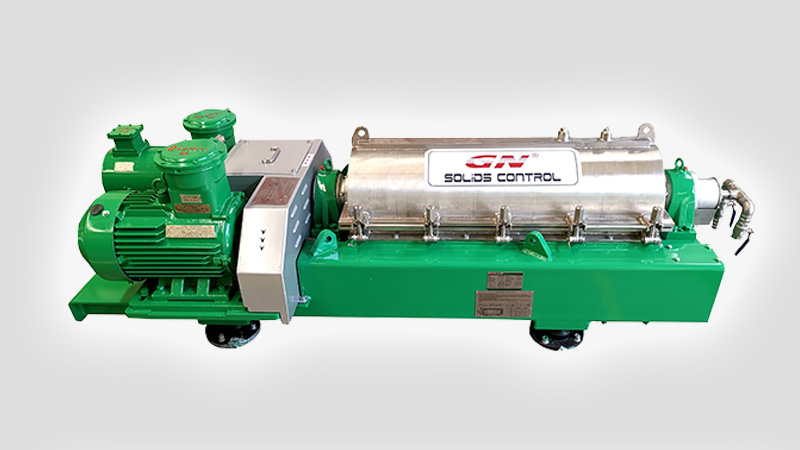

GN T Series Decanter Centrifuge is a cutting-edge solution designed for the efficient dewatering and thickening of slurries in various industrial applications. This advanced piece of equipment stands out for its robust design and versatile features that address the challenges posed by abrasive materials, ensuring longer operational life and lower maintenance costs.

Tungsten Carbide Tiles Protection

One of the key features of the T Series Decanter Centrifuge is the Tungsten Carbide Tiles Protection system, which offers excellent wear resistance. The screw distribution port is equipped with a replaceable carbide sleeve, specifically designed to withstand the wear characteristics of slurry. This makes maintenance straightforward and cost-effective. Additionally, the screw blade is shielded by a replaceable hard alloy plate, further extending the lifespan of critical components.

Hard Facing Wear-Resistant Coating

For enhanced wear resistance, the T Series also offers Hard Facing Wear-Resistant Coating as an optional feature. Depending on material conditions, users can choose between tungsten carbide or Stellite hard alloy cast rods for the wear-resistant layer. The use of robot tungsten carbide or hard alloy cast rod surfacing technology ensures superior quality of surfacing and contributes to the centrifuge’s long-term durability, even under harsh operational conditions.

High-Quality Screw Material

The screw material is also carefully selected to meet the demands of heavy-duty applications. The main material for the screw is duplex stainless steel such as SS2205 or SS2304, offering exceptional corrosion and wear resistance. This choice of material ensures that the centrifuge can handle aggressive substances without compromising performance.

BD (Baffle Disc) for Enhanced Separation

Moreover, the T Series Decanter Centrifuge features innovative designs such as the BD (Baffle Disc), which separates the dewatering area from the sediment area, optimizing liquid pool depth and dewatering efficiency. The use of gradual pitch on the screw further increases pressing force, improving the dryness of the slurry and enhancing separation efficiency.

Conclusion

In summary, GN T Series Decanter Centrifuge offers a robust and adaptable solution for industries requiring efficient dewatering and thickening of slurries. With advanced wear-resistant technologies, high-quality materials, and innovative design features, the T Series is an invaluable tool for improving operational efficiency and reducing maintenance costs in challenging industrial environments.

Understanding the Clarifying Decanter Centrifuge: An Essential Separation Technology

In various industries, the need for efficient solid-liquid separation is crucial to maintaining productivity and environmental compliance. Among the many technologies available, the Clarifying Decanter Centrifuge stands out as an effective solution for processing materials with small particle sizes, low density differences, and moderate viscosity.

What is a Clarifying Decanter Centrifuge?

A Clarifying Decanter Centrifuge is a specialized type of decanter centrifuge designed to separate suspensions into solids and clarified liquid continuously. Unlike traditional decanter centrifuges, which prioritize high solids recovery, a clarifying decanter focuses on achieving high-purity liquid discharge with minimal solids content.

One notable example is the GN Clarifying Decanter Centrifuge, part of the C-series, which features a 20-degree beach angle. This design allows for efficient dewatering of solids while maintaining superior liquid clarification. The centrifuge operates continuously without the need to stop feeding, making it an ideal choice for industries requiring stable and efficient separation processes.

Key Features and Advantages

Efficient Liquid Clarification: The design ensures that suspended solids are effectively separated, producing high-clarity liquid suitable for reuse or discharge

Continuous Operation: Unlike batch processing methods, this centrifuge allows for uninterrupted material input, enhancing productivity.

Ideal for Small Particle Sizes: It is particularly effective for applications where solids have a low density difference from liquids, which can be challenging for traditional separation methods.

Versatile Applications: Industries such as wastewater treatment, food processing, pharmaceuticals, and chemical manufacturing can benefit from the use of a clarifying decanter centrifuge.

Applications of Clarifying Decanter Centrifuge

Wastewater Treatment: Efficiently removes fine suspended solids, improving water quality.

Oil and Gas Industry: Used for separating fine solids from drilling fluids or produced water.

Food and Beverage Processing: Helps in clarifying liquids such as fruit juices, dairy products, and edible oils.

Pharmaceutical Industry: Ensures precise separation in the production of high-purity chemicals and medicines.

Conclusion

A Clarifying Decanter Centrifuge is an essential technology for industries requiring high-quality liquid separation with minimal solid content. The GN Clarifying Decanter, with its optimized design and continuous operation capability, ensures efficient and reliable processing. Whether in wastewater treatment, food production, or chemical industries, this advanced separation technology enhances efficiency and sustainability. If your industry demands high-purity liquid processing, investing in a clarifying decanter centrifuge is a smart and effective choice.