GN Separation is proud to introduce the GNLW454GT Mud Dewatering decanter centrifuge, an advanced and robust solution engineered for the efficient treatment of hydrovac slurry and directional drilling mud. Designed to meet the growing demands of utility construction, trenchless drilling, and hydroexcavation projects, this high-performance decanter centrifuge plays a central role in modern waste management systems where reliable solids–liquid separation is essential. Continue reading

Category Archives: Decanter Centrifuge

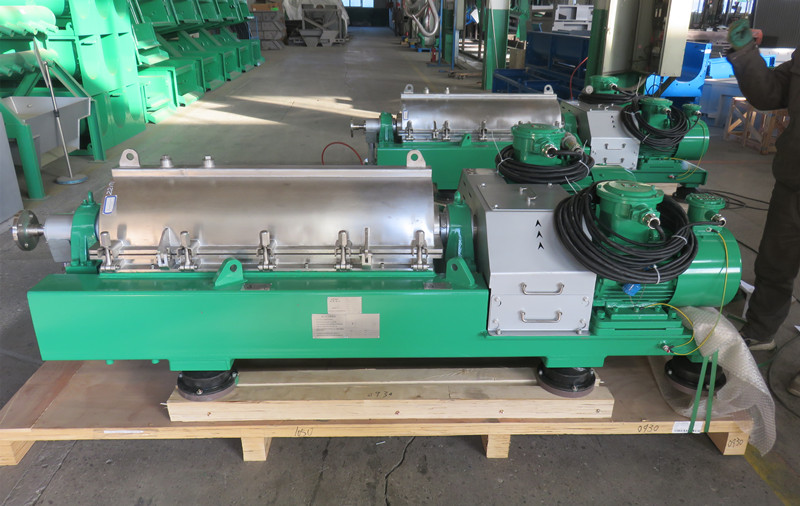

Decanter Centrifuges Specialized in Sludge Dewatering Ready for Inspection

This week, GN Separation completed the assembly of four GNLW224 decanter centrifuges along with their corresponding polymer dosing units at its manufacturing facility. The equipment is scheduled for final inspection and acceptance testing by an overseas client next week. Continue reading

Introduction of the main characteristics of a decanter centrifuge

The decanter centrifuge is one of the separation machines. Compared with other centrifuges, it has its special features, and these special features also enable the centrifuge to better improve the efficiency of the work, so it It can bring convenience to the entire project process.

Regarding its special features, there are mainly the following points:

1. The work of the decanter centrifuge is mainly relying on centrifugal force, which drives the entire centrifuge to perform high-speed work, so that it can exert its effects. It has a relatively strong effect on the dehydration of solids. During the entire dehydration process, manual operations are not required, and fully automated operations can be realized only by controlling it to a certain extent.

- When we are using the decanter centrifuge, it is very necessary to protect and maintain it. The maintenance requirements of the decanter centrifuge are relatively ordinary. Only simple care is required at ordinary times. It requires frequent and complicated maintenance.

- The decanter centrifugelooks like a compact machine in appearance, it occupies a relatively small space, and the entire distribution equipment is relatively simple. During the use of the decanter centrifuge, as long as it is routinely protected and maintained, its service life will be very long.

GN high-end CNC lathes, CNC centers, and CNC gantry milling machines can better ensure the machining accuracy of centrifuge parts. In terms of the dynamic balance of the decanter centrifuge, in addition to the ordinary low and medium speed dynamic balance, GN also applies a high speed dynamic balance process, which can dynamically balance the centrifuge screw and bowl at the actual working speed of the centrifuge. In terms of market applications, GN decanter centrifuges are widely used in the industry, and the products are exported to more than 60 countries and regions in the world, and have won high praise from customers.

Decanter Centrifuges: Trends, Applications, and Safety in Modern Industry

Decanter centrifuges have become a cornerstone in industrial separation processes, offering reliable performance across wastewater treatment, chemical processing, food production, and the oil & gas sector. Their ability to efficiently separate solids from liquids makes them indispensable for operations seeking higher productivity and lower operational costs.

Fig.1 Decanter Centrifuge

The trend in centrifuge technology is moving towards greater automation and control. Modern decanter centrifuges increasingly integrate PLC (Programmable Logic Controller) systems, enabling precise control over rotational speed, feed rate, and cake dryness. PLCs not only optimize separation efficiency but also enhance safety by allowing real-time monitoring and automated fault response, reducing human intervention and operational risk.

In oil and gas applications, safety is paramount. Explosion-proof (Ex) designs for motors, electrical cabinets, and control panels ensure that centrifuges can operate safely in potentially hazardous environments. The combination of robust mechanical design, PLC automation, and explosion-proof technology makes centrifuges a reliable choice for demanding industrial settings, including offshore drilling, refinery wastewater treatment, and drilling mud processing.

At GN Separation, we have delivered solutions worldwide—from pharmaceutical wastewater treatment plants in Europe to power generation facilities in Asia—demonstrating the versatility of decanter centrifuges. As industries demand higher efficiency, safer operation, and remote monitoring, the adoption of PLC-controlled, explosion-proof centrifuges continues to grow, solidifying their role as essential equipment in modern process engineering.

GNLW364-VFD Dewatering Centrifuge for Overseas Pharmaceutical Plant Wastewater Treatment

In the pharmaceutical manufacturing industry, wastewater treatment is one of the most critical yet challenging processes. Pharmaceutical effluents often contain high levels of suspended solids, organic matter, and other complex compounds that must be efficiently separated before discharge or reuse. The GNLW364-VFD dewatering centrifuge is designed to address these challenges, providing a reliable and energy-efficient solution for solid-liquid separation in pharmaceutical wastewater treatment systems.

1. Meeting the High Standards of the Pharmaceutical Industry

Pharmaceutical production demands strict compliance with environmental and regulatory standards. The GNLW364-VFD centrifuge ensures effective dewatering of sludge while maintaining process cleanliness and safety. Constructed with stainless steel 316L contact parts, the unit offers superior corrosion resistance against chemical agents commonly present in pharmaceutical waste streams. Its fully enclosed design minimizes odor emission and contamination, creating a clean and hygienic working environment.

2. Optimized Performance with Variable Frequency Drive (VFD)

Equipped with a VFD control system, the GNLW364 allows operators to precisely adjust the bowl and scroll speeds to suit different feed conditions. This flexibility enables optimal separation efficiency even when the feed composition fluctuates. The system’s intelligent control panel provides real-time monitoring of parameters such as torque, flow rate, and vibration, ensuring stable operation and preventing overload. This adaptability makes it suitable for both primary sludge thickening and final dewatering stages in wastewater treatment lines.

3. Sustainable and Cost-Effective Operation

The dewatering centrifuge significantly reduces the moisture content of sludge, lowering transportation and disposal costs. By improving the dryness of the discharged solids, it minimizes waste volume and supports sustainable resource management. Additionally, the GNLW364-VFD’s energy-efficient drive system helps pharmaceutical plants reduce power consumption and carbon footprint, aligning with global trends toward greener production.

In summary, the GNLW364-VFD dewatering centrifuge is a proven and trusted solution for pharmaceutical wastewater treatment. With its high efficiency, flexibility, and compliance with industry standards, it plays an essential role in helping pharmaceutical facilities achieve cleaner, safer, and more sustainable wastewater management.

What are the frequently asked questions about decanter centrifuge?

Decanter centrifuge is a kind of centrifuge. It is a kind of mud-water mixture that enters the drum through the feed pipe and the screw discharge port. Under the action of the centrifugal force generated by the high-speed rotation of the main engine, the solid particles with larger specific gravity are deposited on the inner wall of the drum, and the spiral blades moving relative to the drum successively scrape the solid particles deposited on the inner wall of the drum and push them out. The slag outlet, the separated clear liquid flows out of the drum machine through the opening of the weir plate.

1. What are the main components of the screw conveyor in the decanter centrifuge?

The screw conveyor of the Decanter centrifuge contains two parts: the drum and the screw, and the screw includes the cylinder and the pusher blade. On the cylinder, there is a feed end and a clear liquid outlet end, which are used to feed materials and flow out the clear liquid after separation.

2. Why can the Decanter centrifuge be used in petrochemical and waste treatment?

Because the decanter centrfuge has the characteristics of compact structure, low energy consumption, strong production capacity, and good adaptability to materials. And with the continuous development of science and technology, the centrifuge has been greatly improved and advanced in terms of structure, performance and technical parameters, and its separation effect has also been improved, so it is used in petrochemical and The treatment of the three wastes is very suitable.

3. Can the decanter centrifuge be used as the main engine of sludge dewatering?

If it is used for sludge dewatering, it is very suitable, and if it has a large aspect ratio and a fully enclosed operation is selected, then it can have a good use effect, because its It has advantages that other sludge dewatering equipment does not have.

4. What is the process of desilting using a decanter centrifuge in a sewage treatment plant?

In the wastewater treatment plant, in the treatment of activated sludge, the whole process of using a decanter centrifuge to desludge is to drive the high-speed rotation of the sludge through a high-speed rotating drum, and then generate centrifugal force to make the sludge The sedimentation of the solid particles accelerates and concentrates on the wall of the drum. Then, through the spiral, the formed mud cake is scraped to the small end of the rotating drum, so that it can be discharged, thereby completing the desliming work.

5. What is the main use of the decanter centrifuge? In addition, what are the unloading conditions of the decanter centrifuge?

Decanter centrifuge is mainly used to remove impurities and suspended solids in the liquid to achieve the role of purification. The general decanter centrifuge, its discharge conditions, mainly including cone angle and bowl speed.

Bearing Replacement Method for Decanter Centrifuge

During operation, a Decanter centrifuge runs at high rotational speeds, which places stringent demands on its bearings. Proper bearing maintenance and replacement are crucial to ensure smooth operation, prevent damage, and extend service life of the Decanter centrifuge.

When the drum bearings show signs of wear or malfunction and require replacement, it is essential to follow the correct procedure. The following steps outline the recommended bearing replacement method to ensure safe and reliable operation.

1. Preparation and Safety

Before starting, ensure the following:

Only qualified personnel should perform disassembly and assembly.

Use professional tools designed for bearing and centrifuge maintenance.

Disconnect the centrifuge from power and follow all lockout/tagout procedures.

Clean the working area and prepare lifting devices for the Decanter centrifuge if needed.

2. Disassembling the Small-End Bearing

Remove the Pressure Plate Bolts

Begin by loosening and removing the bolts from the pressure plate located on the main pulley end.

Extract the Pressure Plate

Use jack screws to evenly push out the end pressure plate. Ensure that all screws are loaded evenly to avoid skewing or deformation.

Remove the Pulley

Using a three-jaw puller, grip the pulley and pull it out carefully.

Mark Components for Reassembly

Clearly mark the relative positions of all components (keys, sleeves, seals, etc.) to ensure correct reinstallation later.

Remove Associated Components

Sequentially disassemble the flat key, taper-end screw, bearing seat sealing ring, and O-ring.

Extract the Bearing Assembly

Place a supporting pad on the bearing end face of the bowl shaft. Then, using a puller tripod, simultaneously remove the bearing sleeve, bearing sleeve gland, bearing, and shaft sleeve as a single unit.

3. Disassembling the Big-End Bearing

The process for the big-end bearing is similar but involves additional components:

Remove the Flange Bolts

Loosen and remove the flange bolts, then take out the differential and spline shaft.

Disassemble the Shaft End Pressure Plate

Remove the bolts from the shaft end pressure plate and use jack screws to push it out evenly. Keep the applied force balanced to avoid tilting.

Remove the Bearing Assembly

Place a pad on the shaft end face, then use a three-jaw puller to remove the connecting flange, bearing seat sealing ring, and flat key.

Extract Bearing Components

As with the small end, use a tripod puller to remove the bearing sleeve, bearing sleeve gland, bearing, and shaft sleeve together.

Make clear alignment marks on the bearing sleeve for accurate reassembly.

4. Key Notes for Reassembly

Ensure all parts are thoroughly cleaned and inspected for wear or damage before reinstallation.

Apply appropriate grease or lubricant to the bearings and seals according to manufacturer specifications.

Install the components in the reverse order of disassembly, aligning all marks made earlier.

After assembly, perform a manual rotation check to confirm smooth movement before restarting the centrifuge.

5. Summary

Although the replacement procedures for the small and big end bearings are similar, careful attention to detail is essential throughout the process. Accurate marking, even force application, and the use of correct tools will ensure safe bearing replacement and help maintain the reliability and longevity of the Decanter centrifuge.

The Role of Decanter Centrifuges in Mining Tailings Dewatering

Mining operations produce enormous volumes of tailings — a slurry composed of fine solids, water, and residual minerals — that must be properly treated before reuse or disposal. Traditional tailings ponds and dams are facing increasing challenges, from limited space to stricter environmental regulations. In this context, decanter centrifuges are transforming tailings management by enabling rapid, efficient solid-liquid separation with minimal environmental impact.

GNLW764: Engineered for Large-Scale Mining Applications

The GNLW764 Decanter Centrifuge, GN Separation’s largest and most powerful model, is specifically designed for large-scale operations such as mining tailings dewatering and TBM slurry treatment. Featuring a 30-inch (764 mm) bowl and heavy-duty construction, it delivers high throughput and reliable performance under demanding conditions. To withstand abrasive slurries, critical wear zones — including the screw conveyor blades and solids discharge ports — are protected with tungsten carbide coatings, ensuring exceptional durability, reduced maintenance, and long service life.

The centrifuge is also equipped with a Variable Frequency Drive (VFD) control cabinet, allowing precise adjustment of rotational speed to suit different materials. Real-time monitoring of vibration and temperature enhances operational safety and ensures stable, efficient performance.

Optimized Dewatering with the GNSJY6000 Flocculation Unit

For even better separation results, GN recommends integrating the GNLW764 with its GNSJY6000 Flocculation Dosing Unit. This automated system accurately injects flocculants into the slurry, causing fine particles to bind into larger clusters that separate more easily. The combined setup boosts solids recovery, increases water clarity, and reduces overall processing costs.

In summary, the GNLW764 Decanter Centrifuge represents a powerful, sustainable solution for modern mining operations. By combining advanced materials, intelligent control, and complementary flocculation technology, it helps operators achieve efficient, eco-friendly, and cost-effective tailings management.

With the GNLW764 Decanter Centrifuges now ready for dispatch, GN Separation is poised to strengthen its position as a professional solution provider in industrial separation technologies, delivering value to clients and contributing to a more sustainable future for the mining industry.

Cause analysis and introduction for the failure of decanter centrifuge

During the feeding process, if the speed of the Decanter centrifuge‘s bowl is too high, it is very easy to cause uneven dispersion of the material, which directly causes the decanter centrifuge to vibrate, so when feeding material, we need to pay attention to this aspect. Continue reading

Key Precautions When Operating a Centrifuge

Centrifuges play a vital role in industries such as chemical processing, pharmaceuticals, food, and mining by separating solids and liquids efficiently. However, improper use can lead to equipment damage, poor separation performance, or even safety hazards. Below are several essential points to consider when operating a centrifuge.

1. Balance and Loading Are Critical

One of the most common causes of vibration and mechanical failure in a centrifuge is unbalanced loading. Before starting the machine, ensure that all containers, tubes, or feed compartments are loaded symmetrically and evenly. In batch-type centrifuges, equal mass on opposite sides of the rotor prevents excessive stress on the bearings and drive system. For continuous decanter or disc centrifuges, steady feed flow is key—sudden surges can upset the balance and cause wear. Always check that covers are properly closed and that no foreign objects are inside the bowl before operation.

2. Monitor Operating Parameters and Maintenance

Centrifuges operate under high rotational speeds and generate significant centrifugal forces. Operators should regularly monitor parameters such as rotational speed (RPM), feed rate, vibration level, and bearing temperature. Exceeding the recommended speed or operating with a worn bearing may lead to mechanical failure.

Routine maintenance is equally important—inspect seals, belts, and lubrication systems frequently. Scheduled replacement of consumable parts such as gaskets and bearings helps maintain separation efficiency and prolong service life. Following the manufacturer’s maintenance intervals ensures stable operation and prevents costly downtime.

3. Prioritize Safety and Training

Because centrifuges involve high-speed rotation, safety precautions are non-negotiable. Operators should be trained on emergency shutdown procedures and aware of the specific materials being processed—some slurries or chemicals may create explosive or corrosive conditions. Always keep safety guards in place, avoid opening covers while the bowl is still spinning, and wear appropriate personal protective equipment (PPE). In addition, it’s good practice to record operating data and perform vibration analysis periodically to detect early signs of imbalance or mechanical fatigue.

Conclusion

Proper operation and maintenance of a centrifuge not only enhance performance but also ensure safety and reliability. By balancing loads carefully, monitoring key parameters, and maintaining strict safety discipline, operators can maximize uptime, extend equipment lifespan, and achieve consistent separation results in any industrial process.