Waste oil is generated during various stages of oil production and processing, including oilfield extraction, pipeline transportation, oil and gas gathering stations, refining operations, and oily wastewater treatment. Efficient recycling and resource recovery from waste oil is essential for both environmental protection and energy conservation.

The treatment of waste oil involves a comprehensive production process based on the principles of centrifugal separation and demulsification. A standard waste oil recycling system consists of the following subsystems: Batching System, Feeding System, Separation System, Conveying System, Control System.

After collection, waste oil is preheated using steam. Additives such as demulsifiers and surfactants are then introduced to break down emulsions and convert oily wastewater into a treatable liquid form.

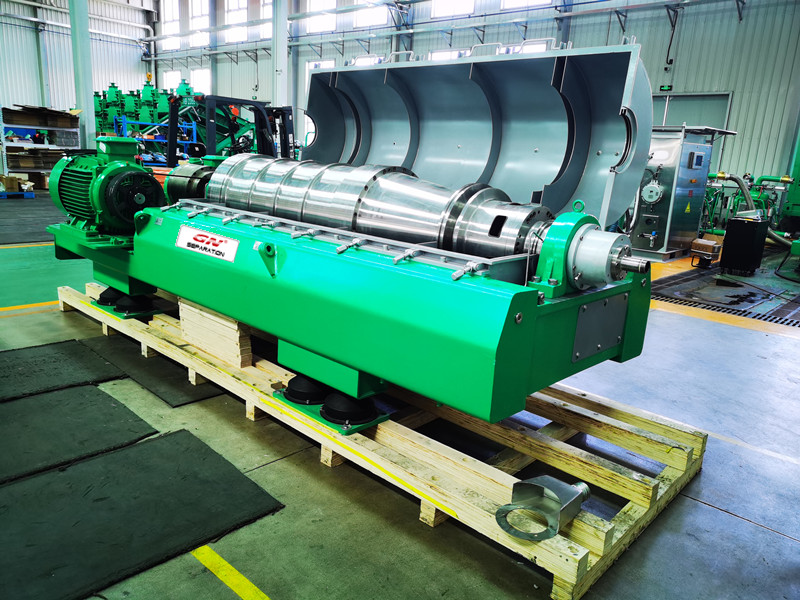

Three-phase decanter centrifuge for continuous separation

The core of the system is a high-efficiency three-phase decanter centrifuge, which enables continuous separation of oil, water, and solids (sludge) from the waste oil.

The oil phase is collected for further purification.

The water phase and oil-water mixture are transferred to a sewage treatment system.

The solid phase is partially dehydrated and may contain recoverable crude oil.

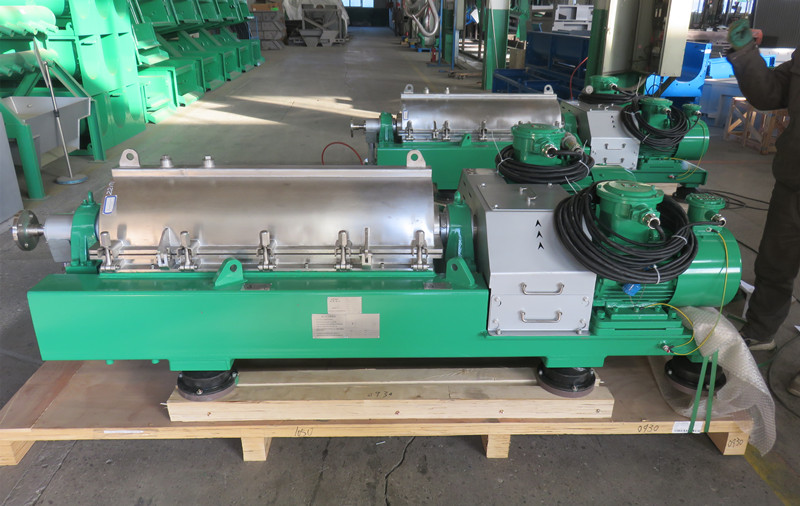

In cases where the separated oil-water mixture and undemulsified water are still complex, a two-phase decanter centrifuge is used for further dewatering.

Downstream Processing and Resource Recovery

Solid Residue: The crude oil content in the separated sludge can be recovered via thermal desorption or used directly as a low-grade fuel for combustion.

Purification: Separated crude oil undergoes secondary purification using a three-phase disc stack separator, producing refined oil suitable for reuse.

Alternative Application: Treatment of Crude Oil Oily Wastewater

The decanter centrifuge system is also effective in processing oily wastewater generated during crude oil handling.

Traditional methods involved direct incineration post-dehydration, leading to significant loss of recoverable oil.

Now, with pretreatment techniques (adding demulsifiers and surfactants), the emulsified oily wastewater is broken down more efficiently.

Once demulsified, the wastewater is transferred to oil traps for gravity separation.

In this setup:

The floating oil is collected.

The sludge layer is further processed.

The middle layer mixture is sent to the wastewater treatment system for final disposal.

Drilling Waste (OBM) Treatment with Decanter Centrifuges

Decanter centrifuges are also used in the treatment of oil-based muds (OBM) from drilling operations. OBMs typically consist of: Base oil, Water, Organoclay, Oil-soluble treatment agents

OBMs offer advantages such as high-temperature resistance, calcium tolerance, wellbore stabilization, and reduced damage to oil and gas formations. However, the waste solids generated from equipment such as shale shakers, centrifuges, and dryers pose serious environmental risks.

Treatment Method:

High-Speed Agitation: Collected OBM wastewater is blended with demulsifiers and surfactants.

Screening: Vibrating screens remove large debris (soil, sand, plastic, gauze, etc.).

Two-Phase Centrifuge: An efficient two-phase decanter centrifuge performs continuous separation of oil, water, and solids.

Thermal Desorption: Remaining oil in the sludge is recovered through thermal desorption.

Oil Recovery: Purified oil is collected and reused.

Final residues typically contain less than 1% oil, meeting environmental safety requirements.

The integration of decanter centrifuge technology into waste oil recycling processes greatly enhances the efficiency of oil recovery, wastewater treatment, and solid waste minimization. Whether applied in crude oil processing, refinery operations, or drilling waste management, these systems offer reliable, scalable, and environmentally friendly solutions that align with modern sustainability goals.