When the decanter centrifuge operates, the high-speed rotation of its drum generates a strong centrifugal force. This force drives solid particles—denser than the liquid phase—toward the inner wall of the drum, forming a solid layer (also known as the solid ring layer due to its annular shape). The liquid, having lower density and subject to less centrifugal force, remains inside the solid layer, forming the liquid ring layer. Continue reading

Author Archives: GN Decanter Centrifuge

Decanter Centrifuge: A Key Technology for Environmental Protection Applications

Environmental protection is a fundamental national policy, and the environmental industry plays a critical role in preventing pollution, preserving natural resources, and enabling sustainable economic growth. In many countries, decanter centrifuges are widely recognized as a preferred choice for sewage and sludge treatment, offering high efficiency and automation in solid-liquid separation processes. Continue reading

Hydraulic-Driven Decanter Centrifuge vs Conventional Decanter: What’s the Difference?

When it comes to solid-liquid separation in industries such as wastewater treatment, oil sludge recovery, and mining, the decanter centrifuge is a vital piece of equipment. While traditional gearbox-driven decanters have dominated the market for decades, hydraulic-driven decanter centrifuges are becoming increasingly popular due to their performance advantages. Here’s a closer look at the key differences between these two technologies.

- Power Transmission: Gearbox vs Hydraulic System

The most fundamental difference lies in how torque is transmitted to the scroll (or screw conveyor). Conventional decanter centrifuges use a mechanical gearbox to generate the differential speed between the bowl and the screw. In contrast, hydraulic-driven decanters use a hydraulic pump and motor system, which offers smoother and more flexible control.

Hydraulic systems can provide higher torque at low differential speeds, which is particularly beneficial in handling high-viscosity or highly concentrated sludges.

- Torque Control and Process Flexibility

Hydraulic-driven decanter centrifuges excel in torque control. They can maintain a stable differential speed even under varying feed conditions, ensuring more consistent performance. This adaptability improves separation efficiency, reduces wear, and enhances the quality of the discharged solids and liquids.

In comparison, mechanical gear-driven systems are more rigid. Although reliable, they may require frequent manual adjustments or risk performance loss when the feed conditions fluctuate significantly.

- Maintenance and Durability

While hydraulic systems may seem complex, they are often easier to maintain in heavy-duty applications. There are fewer mechanical parts under high stress, and the hydraulic components are typically sealed from the harsh process environment.

However, conventional decanters with gearboxes are known for their simplicity and lower upfront cost. For basic or small-scale operations with stable feed characteristics, they remain a practical option.

- Energy Efficiency and Application Suitability

Hydraulic-driven decanters are often more energy-efficient in handling difficult or variable feed, especially when high torque is needed. Industries dealing with oil-based sludges, drilling fluids, or fine particles benefit from the enhanced control and performance.

Conventional decanters are better suited for straightforward, predictable applications where high torque is not a constant requirement.

Conclusion

Choosing between a hydraulic-driven and a conventional decanter centrifuge depends on the application’s complexity, budget, and performance needs. While hydraulic systems offer superior torque control, flexibility, and durability under demanding conditions, conventional decanters provide cost-effective reliability for standard tasks. Understanding these differences is key to selecting the right equipment for your process.

Chinese Centrifuge Powers Municipal Wastewater Treatment in Europe

A New Milestone for GN Separation

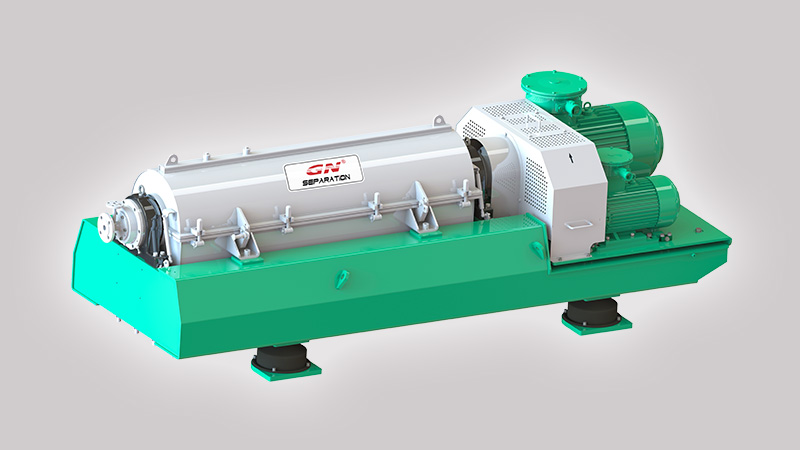

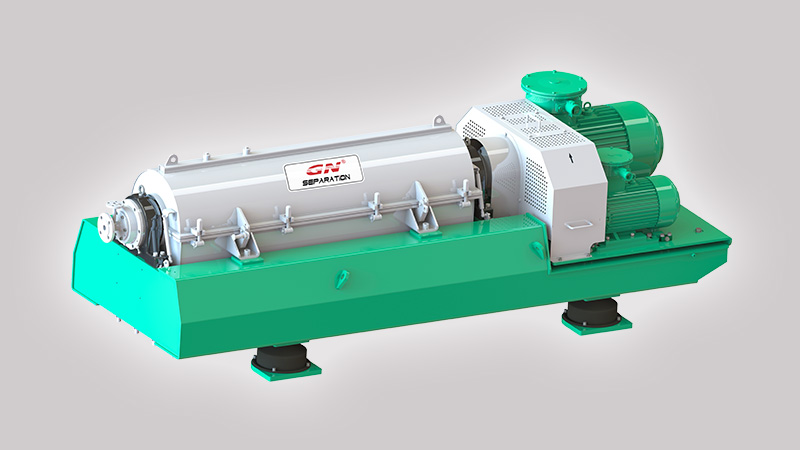

GN Separation has successfully delivered three decanter centrifuges to a leading environmental company in Europe. The shipment includes two GNLW364 models and one GNLW454 model, all of which are designed to meet the complex demands of municipal wastewater treatment. This delivery marks a major milestone for GN Separation, representing a growing recognition of Chinese engineering capabilities in one of the most regulated regions of the world.

Flexible Design Meets Urban Treatment Needs

The delivered centrifuges are not only efficient in operation but also uniquely designed for flexible deployment. They are compact enough to be integrated into containerized units, enabling the development of mobile sludge dewatering systems. These containerized systems are ideal for small and mid-sized wastewater treatment plants that require mobility, limited footprint, and easy relocation. This adaptability makes the GN decanter centrifuges a strong fit for municipalities and contractors seeking plug-and-play solutions with minimal civil works.

Proven Environmental and Operational Benefits

GN centrifuges provide multiple benefits for the wastewater sector. They are engineered to efficiently separate solids from liquids, significantly reducing sludge volume. By recovering reusable process water, they contribute to more sustainable water management. In addition, the equipment supports lower operational costs through reduced energy consumption and maintenance needs. This helps operators meet strict environmental targets while optimizing cost-efficiency.

Global Trust in Chinese Equipment

This project demonstrates the growing acceptance of Chinese-made equipment in mature and regulated markets. European industries are known for their high standards in performance, environmental compliance, and equipment reliability. The fact that GN centrifuges were selected for municipal wastewater treatment in Europe proves that Chinese industrial technology is now trusted beyond developing markets. It is capable of competing with global brands in quality, innovation, and service.

GN Separation continues to expand its footprint globally, providing effective, reliable, and sustainable separation solutions to industries ranging from oil and gas to environmental protection. This successful delivery reinforces the company’s mission to become a respected global brand in the field of industrial separation technology.

How to Increase the Dewatering Efficiency of a Decanter Centrifuge

During the operation of a decanter centrifuge, many users encounter the issue of reduced dewatering efficiency. A common symptom is the prolonged dewatering time, with the resulting solids remaining too wet. This often occurs as solids accumulate inside the centrifuge bowl, affecting the separation performance and increasing cycle duration. Fortunately, there are several ways to optimize and enhance the dewatering capacity of the decanter centrifuge.

1. Increase Rotational Speed and Optimize Drum Design

One of the most effective methods is to increase the rotational speed of the centrifuge drum—within the safe operational limits and provided the materials are non-corrosive or only mildly corrosive. Higher centrifugal force promotes more efficient separation of solids from the liquid phase. Additionally, expanding the filtration surface inside the bowl can significantly enhance water discharge. For example, installing a fine mesh lining or a V-shaped filter baffle increases the permeability and accelerates the dewatering process.

2. Reduce Material Load per Cycle

Another approach is to minimize the amount of feed material per cycle. By reducing the volume of sludge processed at one time and using a more frequent discharge cycle (i.e., “less per run, more runs”), the centrifuge can maintain optimal working conditions and improve overall performance.

3. Modify the Material Characteristics

For viscous or fine-particle sludge, washing the feed (as allowed by the process) and increasing the particle size of the solids can help. The use of flocculants is especially critical—selecting the right type, concentration, and dosage can drastically improve the separation rate. Adjusting the flocculant’s mixing intensity and direction also contributes to a better result.

4. Fine-Tune Operating Parameters

To further boost dewatering performance, it is essential to adjust several key operating parameters:

Bowl speed

Scroll speed and differential (torque curve)

Thickness of the liquid ring layer

Flocculant properties and dosage

Solid loading rate

Field experience has shown that the liquid ring thickness and the scroll speed differential are among the most influential parameters in improving sludge dryness and reducing moisture in the cake.

Maintenance Tips for Long-Term Performance

Regular maintenance is vital to keep your decanter centrifuge running at peak efficiency:

After operation, clean the decanter centrifuge chamber and wipe away any condensed water.

Keep the machine door open after use to allow the internal temperature to return to normal.

Balance all samples before starting centrifugation to avoid mechanical stress.

Disinfect and sterilize the unit as needed, especially when handling biologically active or hazardous materials.

By optimizing both mechanical settings and material preparation, users can greatly improve the dewatering efficiency of decanter centrifuges, reduce maintenance costs, and ensure more reliable operation in demanding industrial environments.

Efficient Resource Recovery from Olive Oil Wastewater with Three-Phase Decanter Centrifuge

Olive oil production is a cornerstone of agriculture in many Mediterranean and Middle Eastern countries. However, this process generates significant amounts of oily wastewater, which can pose serious environmental challenges if not properly treated. Traditional treatment methods are often inefficient and unable to separate the different components of olive oil mill effluent effectively. A three-phase decanter centrifuge presents an advanced solution that not only treats this wastewater but also recovers valuable resources.

Recovering Valuable Olive Oil for Further Refining

Olive oil wastewater still contains a considerable amount of residual oil. With the use of a three-phase decanter centrifuge, this oil can be efficiently separated from the water and solid fractions. The recovered oil, although not suitable for direct consumption, can be sent to refining units to produce usable industrial-grade or cosmetic-grade oil. This significantly increases the overall oil yield for the mill, maximizing profitability and reducing raw material waste.

Purified Water for Reuse or Discharge

The water phase extracted by the decanter centrifuge is much cleaner compared to the raw effluent. While further treatment may be needed to meet strict discharge regulations, the load on biological treatment systems is greatly reduced. In some cases, the clarified water can be reused for cleaning or irrigation, contributing to water conservation in regions where water is a scarce resource.

Organic Solids Reused as Agricultural Fertilizer

The solid fraction separated during the process contains organic residues, pulp, and fine solids. These can be collected and further processed into compost or used directly as soil conditioner. Rich in organic matter and nutrients, these solids support sustainable agriculture and close the loop of circular economy within the olive oil production cycle.

A Sustainable and Cost-Effective Solution for Olive Mills

The three-phase decanter centrifuge operates continuously and requires minimal manual intervention, making it ideal for modern olive oil mills looking to reduce labor and operational costs. Its compact design, high separation efficiency, and ability to handle large volumes of wastewater make it a valuable investment for both small and large-scale producers. Most importantly, it helps producers align with increasingly strict environmental regulations while turning waste into new revenue streams.

Improving Dewatering Efficiency & Enhancing Adaptability of Decanter Centrifuges

During operation, decanter centrifuges may experience prolonged dewatering time and incomplete solid dryness, particularly as solids accumulate in the drum. This issue is common in high-solids or high-viscosity applications. So the common Issue is how to reduce the Dewatering Efficiency of decanter centrifuge.

Soy Protein Extraction Centrifuge Solution

Soybeans are recognized as a complete protein source, containing all essential amino acids required by the human body—amino acids which cannot be synthesized internally. This makes soy protein a valuable alternative to animal-based proteins, both for human consumption and livestock feed. Among the various forms, Soy Protein Isolate (SPI) is the most concentrated, boasting a protein content of up to 90% (dry basis). Continue reading

How Centrifuge Plays a Key Role in Wastewater Treatment

Effective wastewater treatment involves a series of physical, chemical, and biological processes to separate impurities from water. Among the many technologies available, centrifuge stands out as a powerful tool in the sludge dewatering and solid-liquid separation stage.

The Role of Centrifuge in Wastewater Treatment

A centrifuge utilizes high-speed rotational force to separate components of different densities. During the process, suspended solids, sediments, and sludge particles move toward the wall of the spinning bowl, while clarified water exits from the center.

This makes a centrifuge a key piece of equipment for dewatering sludge after the main treatment process. It converts thick, water-rich sludge into a drier, more manageable form — reducing disposal costs and simplifying subsequent handling.

Comparison with Other Equipment (Belt Filter, Plate Filter, MBR)

Compared to belt filter press and plate-and-frame filter, the centrifuge has a smaller footprint and faster processing. It operates in a closed, automated, and continuous manner, reducing human intervention and odor emissions.

Compared to MBR (Membrane Bioreactor), which focuses on liquid-side polishing, the centrifuge performs solid-liquid separation at the back-end, removing excess sludge efficiently. The two technologies are often used in combination: MBR first produces high-purity water, then a centrifuge dewaters the waste sludge afterwards.

How to Select the Right Equipment for Your Application

Choosing the appropriate dewatering equipment depends on numerous factors, including sludge characteristics, flow rate, space, automation requirements, and disposal goals.

For large, continuous operations where space is limited and low maintenance is desirable, a decanter centrifuge is often preferred.

For small scale or batch processing, a belt press or plate filter might be more cost-effective.

Furthermore, the nature of the sludge — whether it’s oily, rich in organics, or heavy sediments — also guides equipment selection.

A centrifuge performs well across a range of viscosities and can handle fluctuations in flow and solid content more robustly than many other methods.

Conclusion

The centrifuge plays a crucial role in modern wastewater treatment, offering efficient, automated, and flexible dewatering of sludge. By understanding its unique benefits and comparing it to alternative equipment, plant designers and operators can select the most appropriate solution to maximize performance and minimize operational cost.

Whether you are designing a new treatment plant or optimizing an existing one, choosing the right dewatering technology is key — and a centrifuge might be exactly what you need.

Enhancing Sugar Mill Efficiency with Industrial Centrifuges

As global sugar demand continues to grow, sugar mills are under increasing pressure to improve processing efficiency, reduce waste, and minimize environmental impact. One of the key technologies that support these goals is the industrial centrifuge, which plays a crucial role in the solid-liquid separation stages of sugar production.

1. Optimizing Sugar Crystallization and Separation

In sugar production—especially from sugarcane and sugar beet—the separation of sugar crystals from molasses is a vital step. Centrifuges provide fast, efficient, and continuous separation by spinning the massecuite at high speed, allowing sugar crystals to be extracted while the remaining molasses is discharged. Compared to traditional batch systems, modern continuous centrifuges improve recovery rates and reduce processing time, enabling mills to increase output without compromising quality.

2. Reducing Waste and Improving Sustainability

Beyond crystal separation, centrifuges are also valuable for handling sugar processing by-products such as filter mud, vinasse, and wastewater sludge. By dewatering these residuals, centrifuges help reduce the volume of waste, lower transportation and disposal costs, and support downstream applications such as bio-composting or energy recovery. This contributes directly to more sustainable and eco-friendly sugar production practices.

3. Reliable Performance in Harsh Mill Environments

Sugar mills often operate in hot, humid, and high-load conditions. Industrial decanter centrifuges and basket centrifuges are engineered to withstand such environments, with features like wear-resistant components, automated controls, and easy maintenance access. Choosing the right centrifuge tailored to your mill’s capacity and process requirements can significantly improve operational reliability and reduce downtime.

Conclusion

As sugar mills modernize to stay competitive, industrial centrifuges have become indispensable equipment in both production and waste management. Whether improving crystal recovery or reducing environmental impact, a high-performance centrifuge system is a smart investment for any forward-thinking sugar producer.