As the golden shades of autumn sweep across the Mongolian landscape, the mining sector prepares for one of its most anticipated events: the Mongolia Mining International 2024 Exhibition. Taking place in the heart of Ulaanbaatar, this esteemed exhibition serves as a global hub for mining professionals, equipment manufacturers, and technology providers to showcase their latest innovations and build strategic partnerships. This year, GN Separation is set to introduce its advanced ore screening and tailings dewatering solutions, underscoring its commitment to sustainability and efficiency in the mining industry.

GN Booth Information:

- Expo Date: 08-10 October 2024

- Venue: Buyant Ukhaa Sport Palace, 10th Khoroo, Khan Uul, Ulaanbaatar, Mongolia

- GN Booth: B03

At the forefront of GN Separation’s display will be two core technologies:

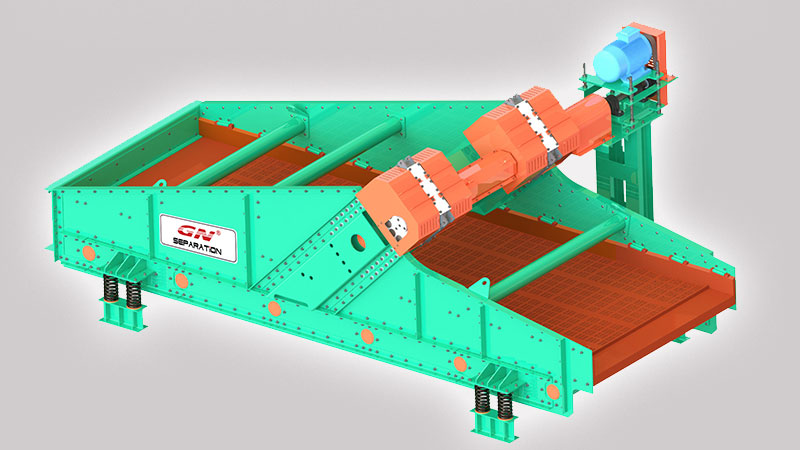

Stack Vibrating Screen

Engineered for high-capacity screening with enhanced precision and durability, the Stack Vibrating Screen utilizes a unique stacked configuration. This design allows multiple decks in a compact structure, significantly boosting screening capacity while minimizing spatial requirements. Suitable for processing a wide array of minerals such as coal, iron ore, gold, and copper, it can be customized to meet the specific needs of various mining operations.

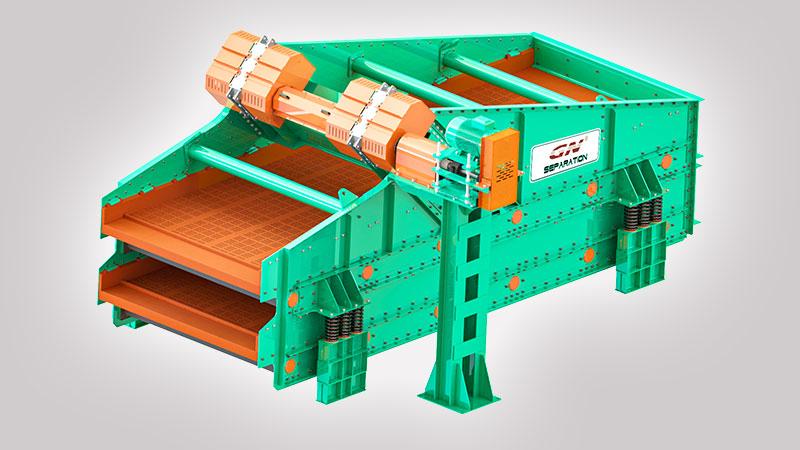

Tailings dewatering centrifuge

Complementing the Stack Vibrating Screen, the Tailings Dewatering Centrifuge optimizes mineral recovery and reduces environmental impact. By applying centrifugal force, it efficiently separates liquids from solid particles in tailings, producing a drier, more manageable material. Its robust design ensures long-lasting performance and low maintenance costs, making it an ideal solution for modern tailings management.

Beyond just innovation, GN Separation is committed to promoting sustainable mining practices, offering solutions that not only increase operational efficiency but also reduce environmental harm. With water conservation and waste reduction becoming critical concerns for the industry, GN’s technologies provide practical answers to these challenges. The 2024 exhibition is set to be a pivotal moment for GN Separation, presenting an opportunity to connect with a global audience and establish new collaborations for future growth.