Introduction

In the dynamic world of oil and gas exploration and production, the centrifuge stands out as a critical tool for efficient separation processes. This versatile machine is employed to separate various components of drilling fluids, cuttings, and produced fluids, ensuring the smooth operation of oilfield activities.

Oil and Gas Application

The primary application of centrifuges in the oil and gas sector is the removal of solids from drilling mud. Drilling mud, or drilling fluid, is essential for lubricating the drill bit, controlling pressure, and carrying cuttings to the surface. Centrifuges help in maintaining the mud’s properties by efficiently removing the unwanted solids, thus extending the mud’s life and reducing the need for frequent replacements.

Water Treatment

Moreover, centrifuges play a vital role in the process of produced water treatment. Produced water, which accompanies oil and gas during extraction, needs to be treated before it can be disposed of or reused. The centrifuge’s ability to separate oil, water, and solids makes it an indispensable part of the produced water treatment process, helping to meet environmental regulations and reduce operational costs.

In addition to these applications, centrifuges are also used in the separation of hydrocarbons from water and the dewatering of hydrocarbon streams. These processes are essential for the quality control and preparation of products for transport and sale.

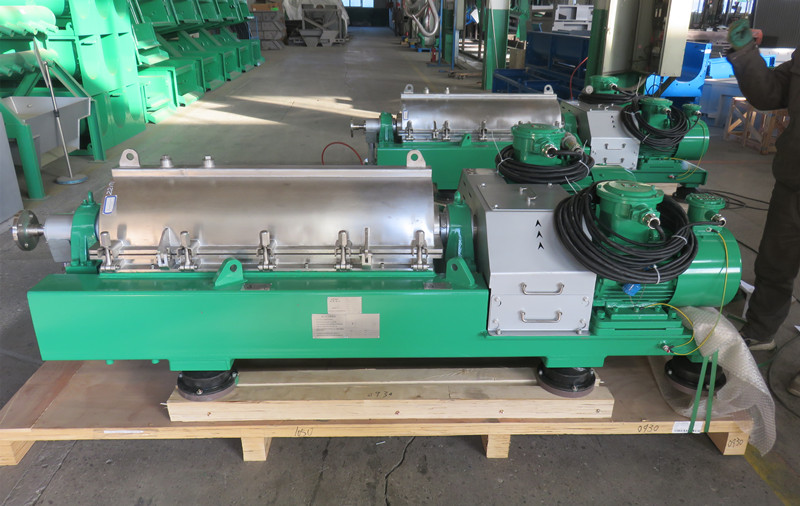

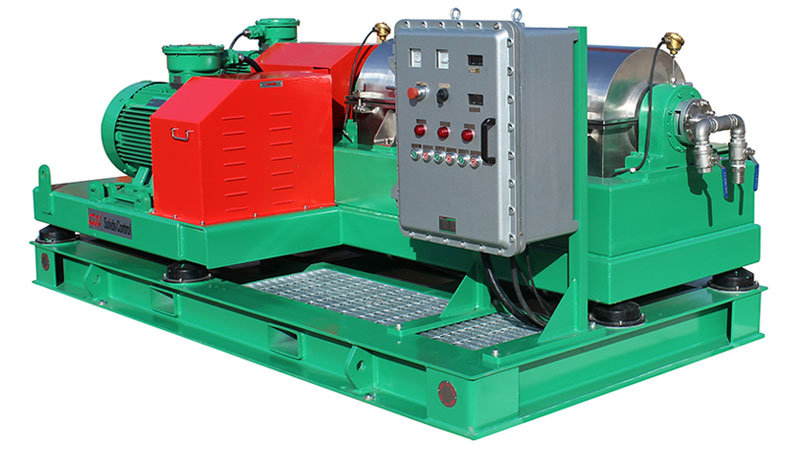

About GN Decanter Centrifuge

The full name of the decanter centrifuge is the horizontal screw decanter centrifuge, which is a widely used equipment in the field of industrial solid-liquid separation. According to the characteristics of different materials in different industries, GN decanter centrifuge is divided into dewatering, separation, and clarifying decanter centrifuge. With centripetal pump technology, GN decanter centrifuge can also realize the 3-phase separation of liquid, liquid, and solids. GN decanter centrifuges are widely used in the industry, and the products are exported to more than 60 countries and regions in the world, and have won high praise from customers.