Continuous Separation for Higher Efficiency

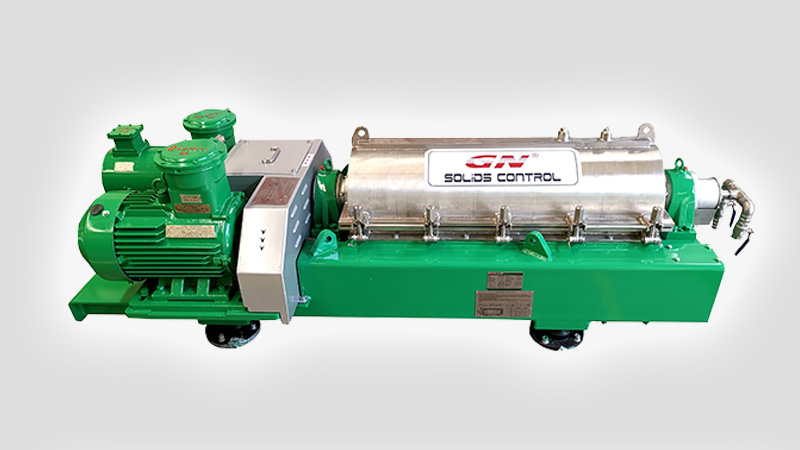

GN Clarifying Decanter Centrifuge, specifically designed as part of the C series, is engineered to provide continuous separation of suspensions into solids and clarified liquids. Unlike batch separation methods, this centrifuge allows for the uninterrupted feed of material, making it ideal for processes requiring consistent and high-quality separation.

Optimized Design for Better Performance

One of the key features of the C series is its 20-degree beach angle, which contributes to a unique design that optimizes the decanter’s performance. The short cone section of the bowl, designed for dewatering, facilitates the rapid removal of solids, while the longer straight section enhances the clarification process. This design ensures that the centrifuge is particularly effective in handling materials with small particle sizes, low density differences between solids and liquids, moderate viscosity, and moderate concentration.

Tailored for Food and Pharmaceutical Industries

What sets the GN Clarifying Decanter apart is its versatility. The machine can be customized to meet the stringent health and safety standards required in the food and pharmaceutical industries. In these sectors, maintaining hygienic conditions is critical, and GN centrifuges are capable of meeting those requirements. Whether it’s the washing or health protection needs in food processing or pharmaceutical applications, the decanter’s design can be tailored to ensure compliance with industry-specific regulations.

Durable and Corrosion-Resistant Construction

The centrifuge’s construction is another standout feature. The shaft caps at both ends and the bowl are crafted from duplex stainless steel (SUS2205 or SUS2304), which is far superior to the performance of traditional SUS304 and SUS316 stainless steels. This material choice enhances durability and resistance to corrosion, ensuring a longer operational lifespan. The components are manufactured through centrifugal casting and die forging, processes that avoid the issues commonly associated with traditional welding methods, such as intergranular corrosion and residual stress.

Innovative Screw Blade for Enhanced Efficiency

Additionally, GN decanter utilizes a CNC-pressed spiral screw blade, which offers superior performance compared to the traditional drawn screw blades. This blade design improves the efficiency of solid transportation and enhances the press force, resulting in drier solids. The screw blade can also be designed with gradual changes in shape to optimize the efficiency of both transport and pressing, further increasing the performance and productivity of the centrifuge.

Conclusion

In conclusion, GN Clarifying Decanter Centrifuge offers a high-efficiency, customized solution for a wide range of separation applications. Its robust construction, hygienic design, and innovative features make it a reliable and effective choice for industries where performance and compliance are essential.