In the rapid development of trenchless technology globally, the Mud Recycling Unit (MRU) has become an indispensable piece of equipment for overseas trenchless projects. Today, let’s discuss the significant role and technical characteristics of this equipment in overseas trenchless projects.

The Importance of Mud Recycling Unit

In trenchless construction processes such as pipe jacking, directional drilling, and microtunnel boring machine (MTBM) applications, mud serves as a crucial auxiliary material. It functions as a lubricant, coolant, supporter, and carrier of soil particles. However, as the project progresses, the mud gradually becomes contaminated and diluted, losing its original properties. This is where the Mud Recycling Unit comes into play.

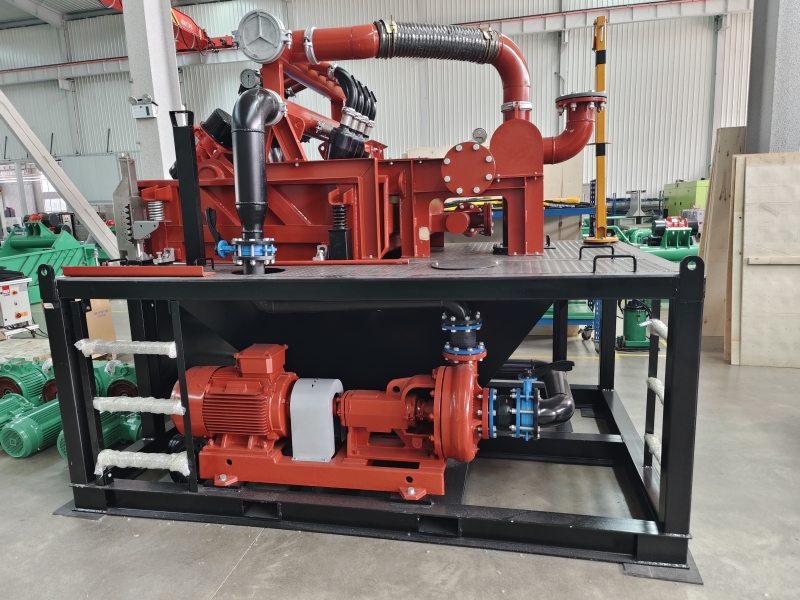

The Mud Recycling Unit effectively separates, purifies, and reuses discarded mud, significantly improving mud utilization and reducing project costs. Meanwhile, the recycled mud maintains good performance, ensuring smooth progress in trenchless construction.

Technical Characteristics of Mud Recycling Unit

Efficient Separation:

The Mud Recycling Unit employs advanced physical or chemical separation techniques to efficiently separate solid particles from the liquid in discarded mud, ensuring the purity of the recycled mud.

Intelligent Control:

The equipment is equipped with an intelligent control system that can continuously monitor the mud’s performance parameters such as density and viscosity, and automatically adjust based on needs, ensuring the stable quality of recycled mud.

Environmental Protection and Energy Conservation:

During the recycling process, the Mud Recycling Unit effectively reduces the discharge of discarded mud, minimizing environmental pollution. Additionally, the equipment itself is designed for energy conservation, lowering energy consumption.

Strong Adaptability:

The Mud Recycling Unit can adapt to different geological conditions and project needs, demonstrating strong adaptability and flexibility.

Application Cases in Overseas Trenchless Projects

In recent years, the Mud Recycling Unit has been widely applied in overseas trenchless projects. For instance, in a drainage pipeline renovation project in a Southeast Asian city, the Mud Recycling Unit was used to recycle and reuse discarded mud. Through practical operation, the equipment not only significantly improved mud utilization and reduced project costs, but also ensured smooth progress in construction.

Conclusion

As an essential piece of equipment in overseas trenchless projects, the Mud Recycling Unit, with its technical characteristics such as efficient separation, intelligent control, environmental protection, and strong adaptability, plays an increasingly significant role in trenchless construction. With the continuous development of trenchless technology, the application prospects of the Mud Recycling Unit will be even broader.