In the vast and diverse landscape of industrial applications, the demand for efficient and reliable equipment that can handle complex processes is paramount. Especially in the realm of salt chemical processing, where precision and durability are key, GN Solids Control has emerged as a leader with its GNLW224 Decanter Centrifuge. This cutting-edge technology is specifically designed to meet the unique challenges faced by overseas salt chemical operations, offering unparalleled performance and versatility.

Understanding the GNLW224 Decanter Centrifuge

The GNLW224 Decanter Centrifuge from GN Solids Control is a high-speed, high-capacity machine engineered to separate solids from liquids in a continuous and efficient manner. It utilizes the principles of centrifugal force to achieve exceptional separation results, making it ideal for a wide range of applications, including salt processing, mineral extraction, and environmental remediation.

Key Features and Benefits

1. High Separation Efficiency

One of the standout features of the GNLW224 is its ability to achieve exceptional separation efficiency. This is achieved through its precision-engineered bowl and screw assembly, which work in harmony to separate even the finest particles from the liquid stream. This ensures that the final product meets the highest quality standards, reducing the need for further processing or refinement.

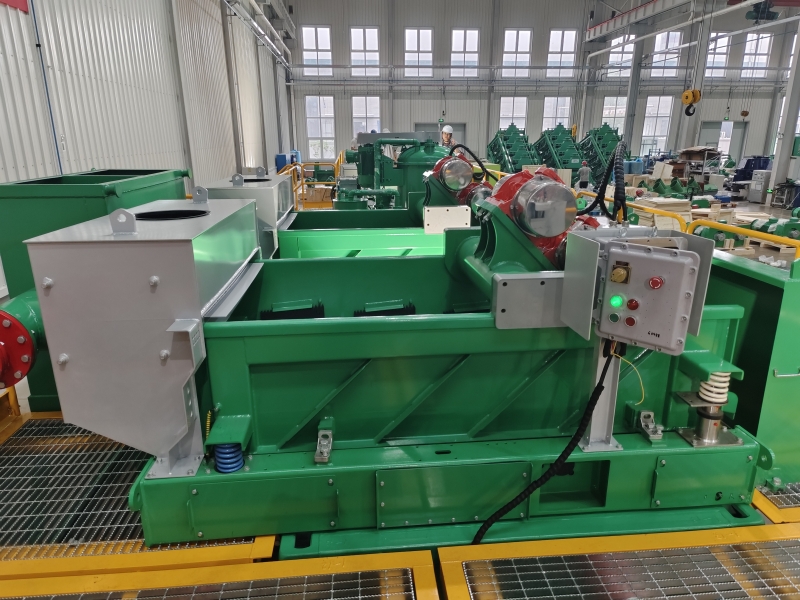

2. Durable Construction

Built to withstand the toughest conditions, the GNLW224 boasts a robust and durable construction. Its heavy-duty materials and precision engineering ensure that the centrifuge can operate continuously without compromise, even in harsh environments. This durability translates into reduced downtime and maintenance costs, maximizing productivity and profitability for overseas salt chemical operations.

3. Versatility

The GNLW224 is designed with versatility in mind, capable of handling a wide range of materials and processes. From salt crystals to brine solutions, this centrifuge can adapt to the specific needs of your operation, delivering consistent results across diverse applications. This versatility makes it a valuable asset for any overseas salt chemical plant looking to streamline its processing operations.

4. Easy Maintenance and Operation

Despite its advanced technology, the GNLW224 is surprisingly easy to maintain and operate. Its intuitive control system and modular design allow for quick and effortless access to critical components, reducing the time and effort required for routine maintenance and repairs. Additionally, GN Solids Control provides comprehensive training and support to ensure that your team is fully equipped to operate and maintain the centrifuge to its full potential.

Applications in Overseas Salt Chemical Processing

The GNLW224 Decanter Centrifuge is an invaluable tool for overseas salt chemical processing operations. Its high separation efficiency and durability make it ideal for tasks such as:

- Separating salt crystals from brine solutions

- Removing impurities from salt products

- Processing specialty salts for use in industrial or consumer applications

- Environmental remediation projects involving salt-laden wastewater

Conclusion

In conclusion, the GN Solids Control GNLW224 Decanter Centrifuge is a game-changer for overseas salt chemical processing operations. Its combination of high separation efficiency, durable construction, versatility, and ease of operation make it the perfect choice for any operation looking to streamline its processing operations and maximize productivity. If you’re in the market for a reliable and efficient centrifuge for your salt chemical processing needs, look no further than the GNLW224 from GN Solids Control.