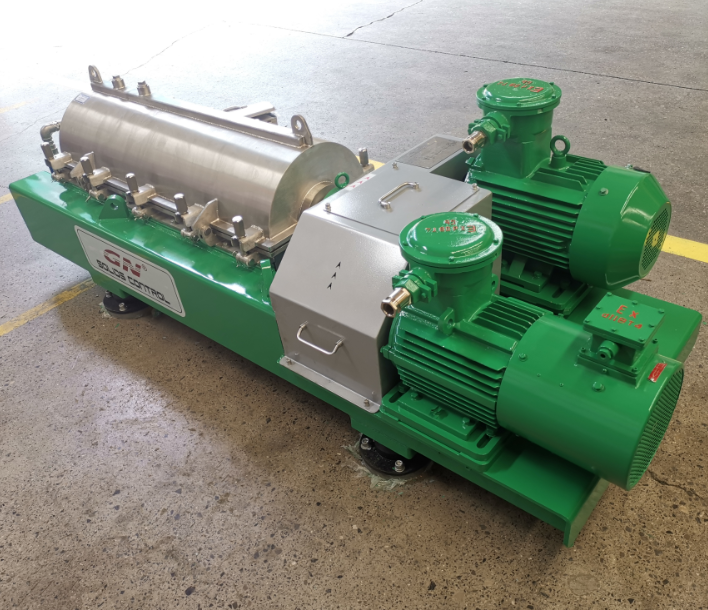

Proper installation and safety management are critical when installing a decanter centrifuge. A decanter centrifuge is a high-speed rotating machine, and failure to follow correct safety procedures may result in serious injury, equipment damage, or production interruptions. Therefore, all personnel involved in installation, commissioning, operation, and maintenance must strictly follow safety guidelines and technical instructions.

General Safety Requirements

Before installation begins, operators and technicians should fully understand the structure, working principle, and operating characteristics of the decanter centrifuge. Reading and becoming familiar with the operation and maintenance manual is mandatory. Only trained personnel should be allowed to work on or near the centrifuge. When working around the equipment, appropriate personal protective equipment (PPE), such as helmets, gloves, safety shoes, and eye protection, should be used to reduce potential risks.

Electrical and Control Safety

Electrical safety is one of the most important aspects of decanter centrifuge installation. Before performing any wiring, inspection, or maintenance work, the power supply must be completely disconnected by switching off the motor starter, fuse box, or circuit breaker. After disconnection, always verify that the power has been cut off to prevent accidental startup. This step is essential, especially in automated systems where unexpected activation may occur.

If the decanter centrifuge is equipped with remote control or automatic operation functions, clear warning signs must be installed near the equipment to indicate that the machine may start automatically. All electrical wiring and control components must comply with applicable electrical standards. Proper grounding of the centrifuge and related equipment is mandatory, and all electrical work must be performed by certified electricians.

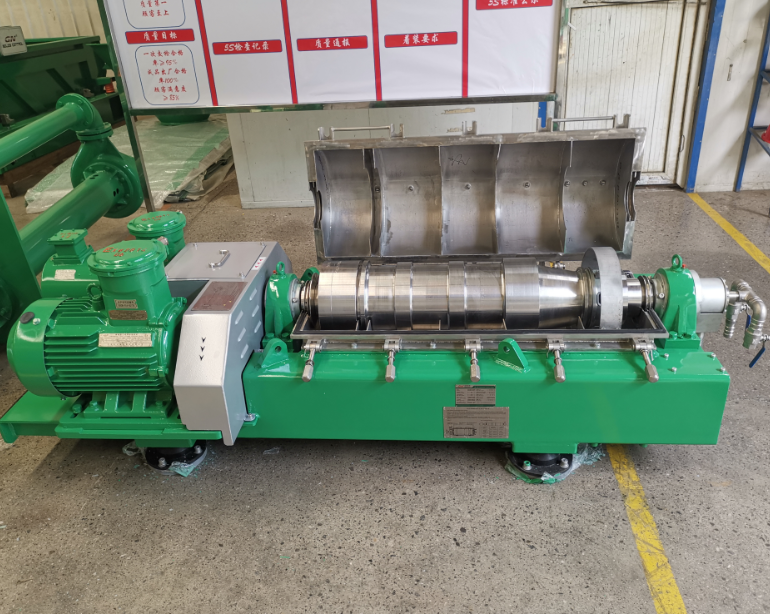

Mechanical Safety and Protective Devices

During operation, it is strictly forbidden to place hands, clothing, or tools near rotating or moving parts, including the feed inlet and discharge outlets. The decanter centrifuge must never be started unless all protective covers, guards, and sight glasses are properly installed. Removing protective devices while the centrifuge is running is strictly prohibited. All safety covers must remain in good condition to ensure effective protection.

Importance of Correct Installation

Following correct installation and safety precautions helps ensure stable operation, extends equipment service life, and reduces the risk of unplanned shutdowns. Proper safety management also protects personnel and ensures that the decanter centrifuge operates efficiently and reliably throughout its service cycle.