GN waste oil recovery decanter centrifuges are tailored to fulfill the separation needs of the waste oil processing sector. Waste oil typically contains oil, water, and solids, and GN Separation equipment provides efficient solutions for separating these three phases while maximizing oil recovery.

Waste Oil Recovery Treatment

The waste oil recovery and treatment process involves handling various types of waste oil, including:

- Solids, water, and oil found at the bottom of oil storage tanks.

- Oily residues and slop oils generated from oil refineries.

- Oil sludge lagoons containing a mixture of oil, water, and solids.

- Oil-water mixtures from ship ballasts, which are the spaces in a ship’s hull that are partially or completely filled with water to improve stability.

- Sludge treatment from API (American Petroleum Institute) oil-water separators, which are used to separate oil and water in industrial settings.

- Discarded lubricant oils and emulsions from various industries.

- Industrial oil/water and emulsion waste streams, which may contain a mix of hydrocarbons, water, and other contaminants.

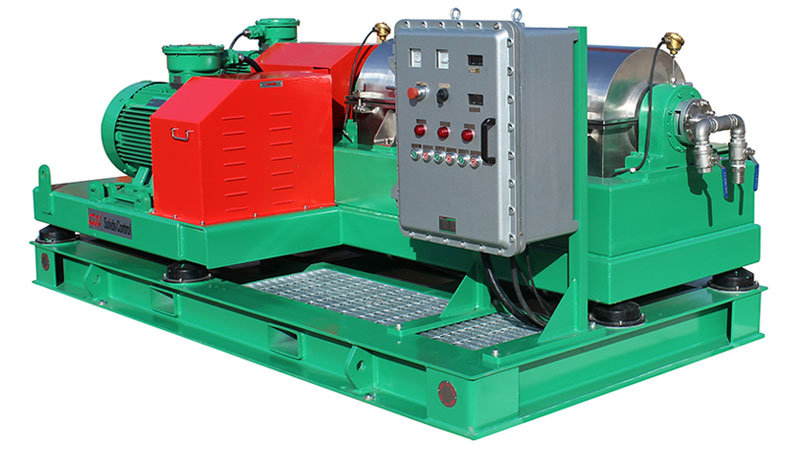

Advantages of GN Waste Oil Recovery Centrifuge

- More sizes available: The centrifuge is available in various sizes with a large length/diameter ratio of 4.2:1 or greater, allowing for greater flexibility in handling different volumes and types of waste oil.

- High G force: With a G force of up to over 3000 G, the centrifuge can effectively separate oil, water, and solids, ensuring high separation efficiency and oil recovery.

- Two-phase or three-phase separation: The centrifuge can be configured as a two-phase or three-phase separation decanter, depending on the specific needs of the waste oil recovery process.

- Explosion-proof design: The nitrogen purged centrifuge is designed for explosion-proof operation, ensuring safety in hazardous environments.

- Corrosion-resistant materials: The duplex stainless steel bowl is resistant to corrosion, extending the lifespan of the centrifuge and reducing maintenance costs.

- Automated operation: The centrifuge is equipped with VFD control, HMI, and PLC for automated operation, reducing the need for manual intervention and improving process efficiency.

- Adjustable parameters: The bowl speed, differential speed, and pump capacity can be adjusted to optimize the separation process for different types of waste oil.

- Wear protection: Various scroll and bowl wear protection systems made of tungsten carbide materials ensure the durability of the centrifuge and reduce the need for frequent repairs.

- Customized design: The centrifuge can be customized according to clients’ requirements, allowing for greater flexibility in meeting specific process needs.

- Global support: With worldwide partners and branches, GN offers fast support for waste oil recovery processes, ensuring that clients can rely on reliable and efficient service.