The thickness of the liquid-ring layer is a critical operating parameter in decanter centrifuge optimization. It directly influences the effective settling volume inside the bowl and the length of the drying (beach) zone, thereby affecting the overall sludge dewatering performance.

Adjustment of Liquid-Ring Layer Thickness

In most decanter centrifuges, the liquid-ring layer thickness is adjusted by changing the height of the liquid level baffle when the machine is in a stopped condition. During adjustment, it is essential that all liquid level baffles are set to the same height. Inconsistent baffle heights may lead to severe vibration during operation and negatively impact machine stability.

Some advanced designs from certain manufacturers allow for automatic adjustment of the liquid-ring layer thickness, offering greater operational flexibility and convenience.

Influence on Separation Performance

Increasing the thickness of the liquid-ring layer expands the sedimentation area and extends the residence time of the material inside the centrifuge. As a result, clarified liquid quality is improved, with lower residual solids content in the centrate.

Conversely, reducing the liquid-ring layer thickness shortens the sedimentation zone and increases the effective beach length. This typically results in higher dry solids content in the discharged cake, but often at the expense of reduced filtrate clarity.

Optimizing the Balance Between Cake Dryness and Filtrate Quality

Therefore, the liquid level baffle height should be adjusted carefully to achieve the optimal balance between cake dryness and filtrate quality, based on specific material characteristics and process requirements.

In practice, many decanter centrifuge suppliers preset the liquid level baffle position during factory commissioning. However, due to variations in feed properties, flow rate, and on-site operating conditions, further adjustment may be required after installation. If separation performance is not satisfactory, it is recommended to consult with the equipment supplier or process engineer to fine-tune the liquid-ring layer thickness on site.

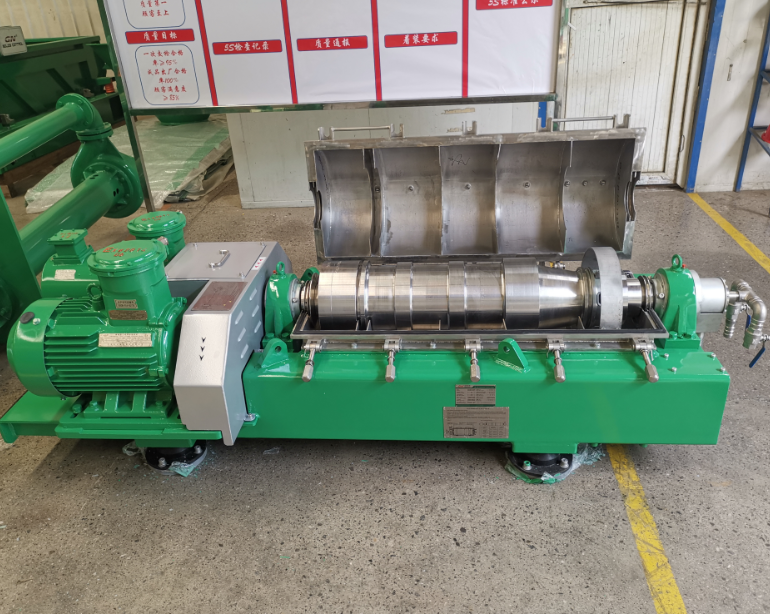

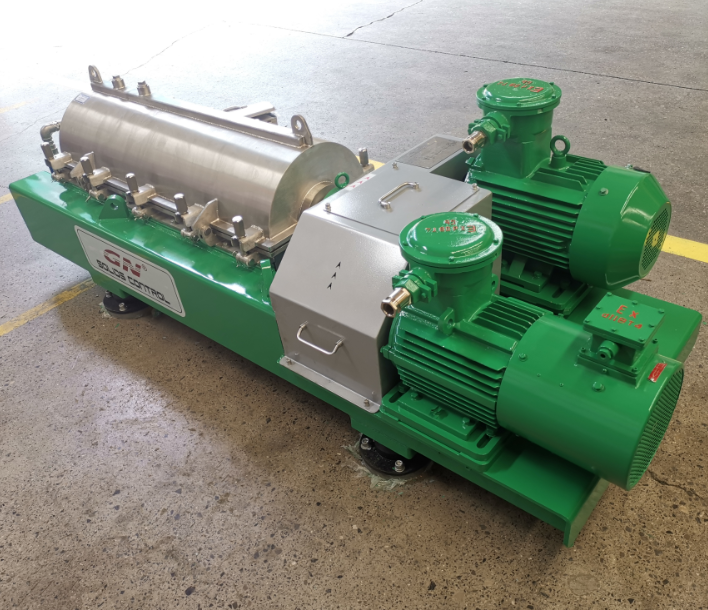

GN Complete Dewatering Solutions

GN Separation not only supplies high-quality decanter centrifuges, but also provides complete turnkey dewatering solutions, including material conveying, classification, and sludge dewatering systems. Backed by GN’s comprehensive range of separation and conveying equipment, we continue to deliver reliable, efficient, and advanced solutions to customers worldwide.