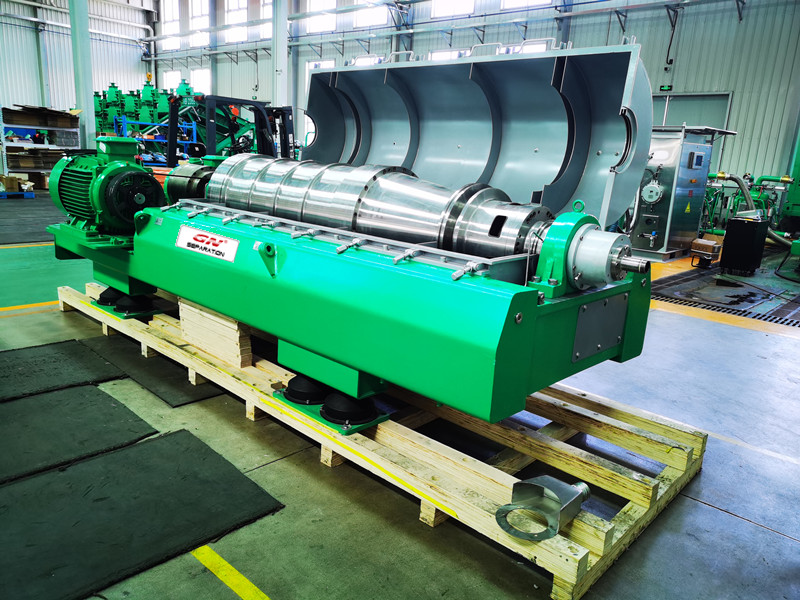

The decanter centrifuge performs centrifugal separation on two- or three-phase liquid-solid heterogeneous mixtures with different densities. During operation, the main motor drives the two pulleys simultaneously, which in turn drive the bowl and the helical screw through a gear or cycloidal pin-wheel differential. This ensures a fixed relative differential speed between the bowl and the screw, allowing the materials to be separated efficiently at high speed.

To achieve optimal separation performance and maintain equipment stability, it is crucial to balance the centrifuge bowl and its contents. In decanter centrifuge, the rotor is mounted on a very thin shaft; therefore, the weight difference between the balanced centrifuge tubes must not exceed the tolerance specified in the equipment manual. For example, in preparative ultracentrifuges, the weight difference between two centrifuge tubes must not exceed 0.1 g.

When using decanter centrifuge bowls with sleeves, the sleeves must also be balanced and must not be interchanged between different centrifuges. After achieving proper balance, materials should be added symmetrically to avoid uneven centrifugal forces, which could damage the spindle and cause serious accidents. Once the balanced bowl is in place, close the centrifuge cover, turn on the power supply, and set the centrifuge speed and operational parameters.

As the separation cycle approaches completion, the deceleration or speed adjustment control should be engaged to gradually slow the decanter centrifuge. After the centrifuge comes to a complete stop, open the cover, remove the bowl, turn off the power, and unplug the machine. Clean the centrifuge, including the chamber, bowl, sleeves, and other components, to ensure proper maintenance.

Modern decanter centrifuges are also equipped with automatic control systems. After setting parameters such as centrifugal speed, separation time, temperature, and vacuum, the operator simply activates the system. The centrifuge will run automatically, monitor the set parameters, and record operational time. Upon completion, the centrifuge will automatically stop, and the deceleration device will engage to safely bring the machine to rest.