Effective wastewater treatment involves a series of physical, chemical, and biological processes to separate impurities from water. Among the many technologies available, centrifuge stands out as a powerful tool in the sludge dewatering and solid-liquid separation stage.

The Role of Centrifuge in Wastewater Treatment

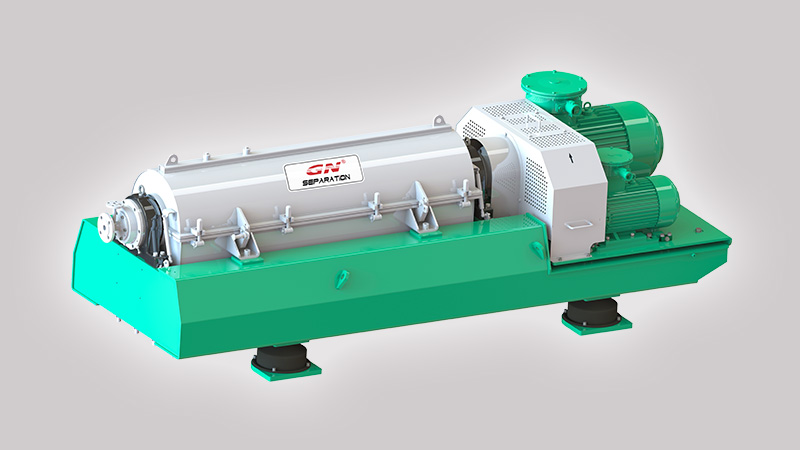

A centrifuge utilizes high-speed rotational force to separate components of different densities. During the process, suspended solids, sediments, and sludge particles move toward the wall of the spinning bowl, while clarified water exits from the center.

This makes a centrifuge a key piece of equipment for dewatering sludge after the main treatment process. It converts thick, water-rich sludge into a drier, more manageable form — reducing disposal costs and simplifying subsequent handling.

Comparison with Other Equipment (Belt Filter, Plate Filter, MBR)

Compared to belt filter press and plate-and-frame filter, the centrifuge has a smaller footprint and faster processing. It operates in a closed, automated, and continuous manner, reducing human intervention and odor emissions.

Compared to MBR (Membrane Bioreactor), which focuses on liquid-side polishing, the centrifuge performs solid-liquid separation at the back-end, removing excess sludge efficiently. The two technologies are often used in combination: MBR first produces high-purity water, then a centrifuge dewaters the waste sludge afterwards.

How to Select the Right Equipment for Your Application

Choosing the appropriate dewatering equipment depends on numerous factors, including sludge characteristics, flow rate, space, automation requirements, and disposal goals.

For large, continuous operations where space is limited and low maintenance is desirable, a decanter centrifuge is often preferred.

For small scale or batch processing, a belt press or plate filter might be more cost-effective.

Furthermore, the nature of the sludge — whether it’s oily, rich in organics, or heavy sediments — also guides equipment selection.

A centrifuge performs well across a range of viscosities and can handle fluctuations in flow and solid content more robustly than many other methods.

Conclusion

The centrifuge plays a crucial role in modern wastewater treatment, offering efficient, automated, and flexible dewatering of sludge. By understanding its unique benefits and comparing it to alternative equipment, plant designers and operators can select the most appropriate solution to maximize performance and minimize operational cost.

Whether you are designing a new treatment plant or optimizing an existing one, choosing the right dewatering technology is key — and a centrifuge might be exactly what you need.