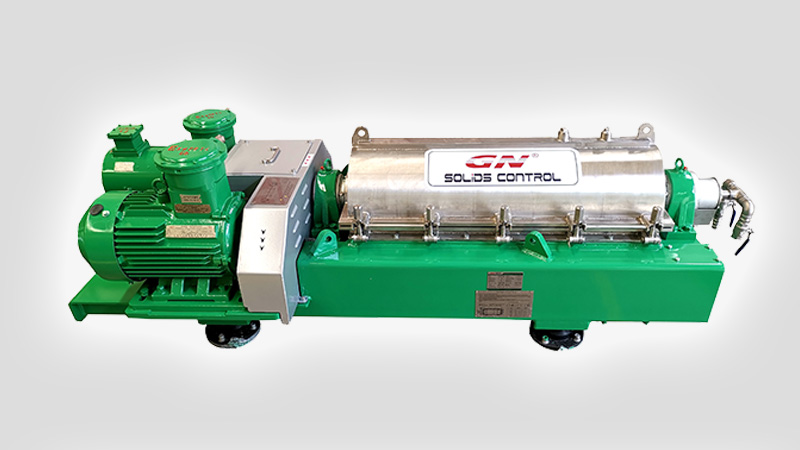

In modern industrial applications, separation technology plays a critical role in ensuring efficiency, quality, and compliance with stringent industry standards. Among various separation solutions, GN C Series Clarifying Decanter Centrifuge stands out for its advanced design and enhanced performance. This blog explores the key features of this high-efficiency centrifuge and how it benefits industries such as food processing, pharmaceuticals, and wastewater treatment.

Optimized Design for Effective Clarification

One of the defining characteristics of the C Series Clarifying Decanter Centrifuge is its unique bowl geometry. With a 20-degree beach angle, the decanter has a relatively short cone section for dewatering but a longer straight section. This extended clarifying section enhances the separation of fine particles, resulting in improved clarity of the discharged liquid. Such a design makes the centrifuge highly effective in applications requiring high-purity separation.

Compliance with Hygiene Standards

The C Series can be designed and manufactured according to strict hygiene standards applicable to the food and pharmaceutical industries. This ensures that the equipment meets the necessary requirements for cleanliness and safety. The ease of cleaning and sanitation makes it ideal for handling sensitive materials, reducing the risk of contamination.

Superior Material Construction

To ensure durability, corrosion resistance, and mechanical strength, the key components of the C Series centrifuge, including the bowl and shaft caps, are made from duplex stainless steel (SUS2205 or SUS2304) using centrifugal casting technology. This material choice provides superior performance compared to SUS304 and SUS316, offering better resistance to intergranular corrosion and higher mechanical strength. Additionally, centrifugal casting and die forging processes are used instead of traditional welding methods to eliminate issues like residual stress and weak structural points.

Advanced Screw Blade Technology for Efficient Solids Discharge

The screw conveyor, a crucial component responsible for transporting solids within the centrifuge, is manufactured using CNC spiral blade forming technology. Compared to traditional drawing methods, this process results in higher slag conveying efficiency. Furthermore, the screw blades can be designed with a gradual change structure, optimizing the transport and compression of solids to achieve drier discharge. This not only improves efficiency but also enhances overall operational performance.

Conclusion

The C Series Clarifying Decanter Centrifuge is an advanced separation solution engineered to meet the demands of various industries. Its optimized bowl design, hygienic manufacturing standards, superior material selection, and innovative screw blade technology set it apart from conventional decanters. Whether in food processing, pharmaceuticals, or wastewater treatment, this centrifuge ensures efficient solid-liquid separation with enhanced durability and reliability.

If you are looking for a high-performance decanter centrifuge for clarification and dewatering, the C Series is a reliable and efficient choice. Contact GN Separation to learn more about how this technology can benefit your application!