1. Importance of Thorough Sugar Beet Cleaning

In sugar production, the quality of raw material preparation directly impacts the efficiency of the entire process. For sugar beet processing plants, one of the most critical early steps is the cleaning of harvested beets. Sugar beets are typically delivered from the field covered in soil, stones, and other debris. If not properly removed, these impurities can damage downstream equipment, reduce sugar extraction efficiency, and increase maintenance costs.

Traditionally, sugar beets are cleaned using water-based systems like flumes and drum washers. However, these systems generate large volumes of wastewater mixed with fine solids. The separation of these solids from the washing water is essential for reusing the water and maintaining plant hygiene and process stability. This is where centrifuge technology becomes highly valuable.

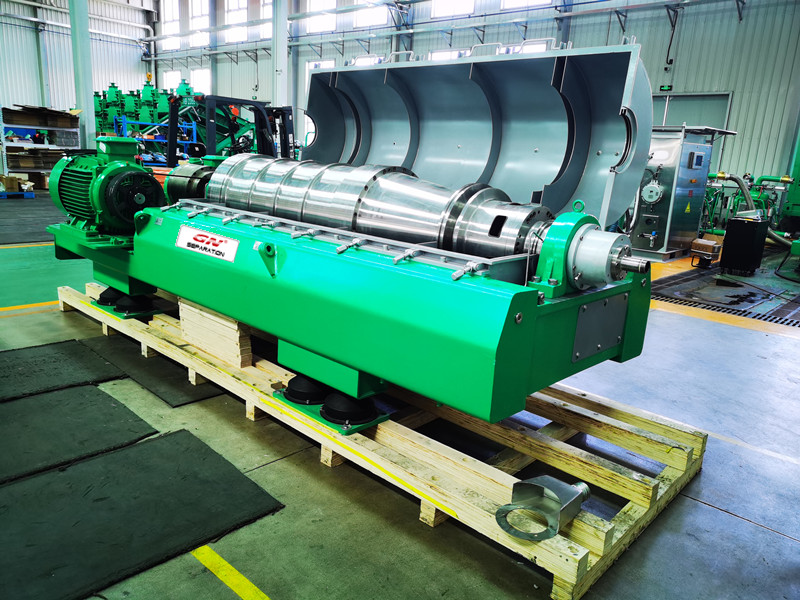

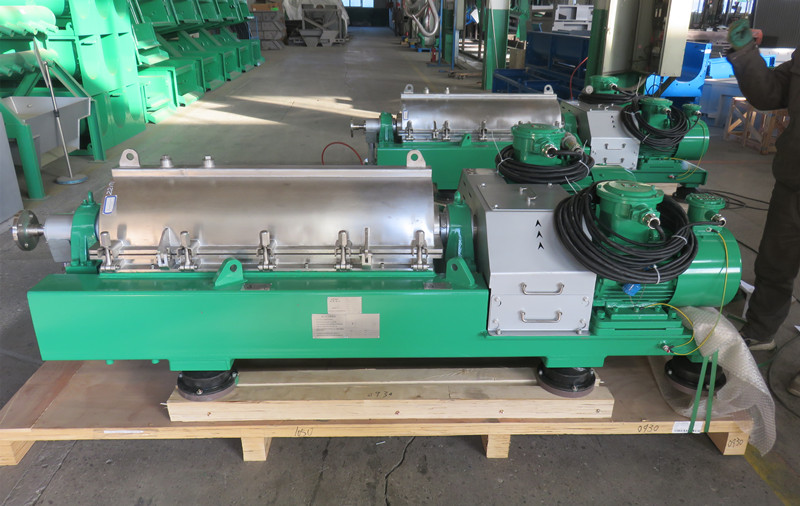

2. Centrifuges for Solids Removal and Water Recycling

Modern beet washing systems increasingly rely on decanter centrifuges to handle the wastewater generated during the cleaning process. A decanter centrifuge is designed to continuously separate suspended solids from liquids using high-speed rotational force. In sugar beet washing, it efficiently removes soil, sand, and organic particles from the wash water.

The benefits are twofold:

First, the clarified water can be reused in the washing loop, significantly reducing the consumption of fresh water and lowering utility costs.

Second, the dewatered solids (beet soil and debris) are discharged as a dry cake, which is easier and more cost-effective to handle, transport, or dispose of.

This not only enhances the environmental sustainability of the operation but also increases process uptime, as clean water reduces the wear on pumps, nozzles, and washing machinery.

3. Key Benefits of Using Centrifuges in Beet Processing

The integration of a centrifuge into the sugar beet cleaning process provides multiple operational advantages:

✅ Water Savings: Recycled water reduces dependency on fresh water sources.

✅ Efficient Solids Removal: Reduces buildup in the system and minimizes downtime.

✅ Lower Maintenance Costs: Clean water means less abrasion and damage to equipment.

✅ Sustainable Operations: Supports environmental goals by reducing water waste and solid disposal volumes.

✅ Improved Plant Performance: Consistent cleaning leads to better sugar extraction rates.

Many modern sugar factories around the world have already incorporated high-performance centrifuge systems into their cleaning stations as part of their effort to boost production efficiency while meeting environmental regulations.