Decanter centrifuges have specific characteristics when utilized for scum processing that set them apart from other types of equipment. By understanding these key features, users can optimize their use of the equipment and maximize its performance. Achieving a deep understanding of these characteristics is essential for ensuring that the decanter centrifuge operates at peak efficiency in practical applications. Continue reading

Monthly Archives: February 2025

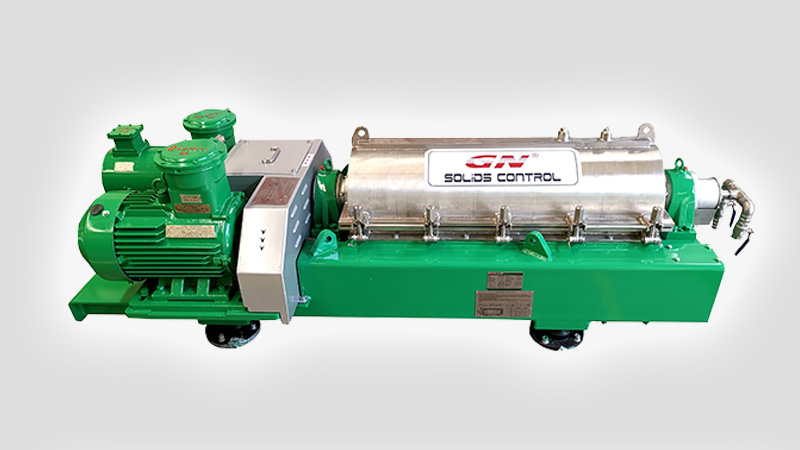

Why GN Dewatering Centrifuge Stands Out in the Market

GN T Series Dewatering Centrifuge offers a combination of advanced design, high-performance features, and durability, making it a leading choice in the dewatering centrifuge market.

One key feature is the 8.5-degree beach angle, which results in a longer cone section. This extended drying and dewatering area improves the performance of the centrifuge, leading to drier solid materials being discharged, making it ideal for applications that require higher dryness.

Superior Construction and Materials

GN centrifuge is built to last, with key components like the shaft caps and bowl made from duplex stainless steel (SUS2205 or SUS2304) through centrifugal casting. This provides greater corrosion resistance and durability compared to traditional stainless steel like SUS304 or SUS316. It also prevents issues related to intergranular corrosion and stress from welding, which are common with other manufacturing methods.

The wear-resistant sleeve at the solid discharge port is made from high-quality tungsten carbide, which ensures extreme durability and resistance to wear. This material is highly resistant to abrasion, ensuring the centrifuge can operate for extended periods without requiring frequent maintenance.

Efficient and Flexible Operation

The T Series centrifuge also features an adjustable overflow weir plate, which allows for easy modification of the liquid pool depth. This flexibility helps users adjust the centrifuge to meet the specific requirements for material dryness and clarity under varying operating conditions.

GN’s centrifuge design is space-efficient, with both motors located at one end of the unit, which saves valuable space and reduces the risk of motor damage due to material leakage. Additionally, the collection box cover on smaller models is assisted by a gas spring for easy, safe access during maintenance.

Premium Bearings and Control System

The centrifuge uses high-quality SKF bearings for durability and long service life. An optional automatic lubrication system is available to reduce wear further. The electric control panel typically includes world-class components like VFD, PLC, and HMI, with the option to provide explosion-proof panels certified by CNEX, ATEX, or IECEX.

Conclusion

In conclusion, GN T Series Dewatering Centrifuge combines advanced engineering with durable materials and superior performance. These features make it an excellent choice for industries seeking reliable, cost-effective dewatering solutions.

The Working Principle of Sludge Dewatering Decanter Centrifuge

The working principle of sludge dewatering decanter centrifuge involves high-speed rotation of the bowl and screw in the same direction, with a specific differential speed between them. The material is continuously fed into the inner cylinder of the screw conveyor via the feed pipe, where it is then accelerated and directed into the rotating bowl. Heavier solids settle on the bowl wall, forming a layer of sediment. The screw conveyor pushes the settled solids toward the conical end of the bowl, where they are discharged through the slag outlet. Meanwhile, the lighter liquid phase forms an inner liquid ring, which overflows from the large end of the bowl and exits through the liquid discharge port.

This decanter centrifuge operates continuously, allowing for the simultaneous feeding, separating, washing, and discharging of materials. It features a compact design, stable operation, high capacity, strong adaptability, and easy maintenance. It is suitable for separating suspensions with solid particles larger than 0.005 mm and concentrations ranging from 2% to 40%. It is commonly used in industries like sludge dewatering, chemicals, light manufacturing, pharmaceuticals, food, and environmental protection.

In the field of environmental protection, the decanter centrifuge is primarily used for dewatering the sludge generated during industrial and municipal sewage treatment processes. As global environmental concerns continue to rise, the importance of decanter centrifuges has become more pronounced.

Historically, sewage and treatment plants used methods like self-sedimentation or belt filter presses to dewater and concentrate sludge. Tests show that these methods can reduce the water content of sludge from 98% to 80%, decreasing its volume by up to tenfold. Thanks to its high processing capacity, automated operation, and effective dehydration performance, the decanter centrifuge has gained widespread adoption in the environmental protection sector. In fact, decanter centrifuge sales make up about half of all centrifuge sales, underscoring its indispensable role. Globally, the sludge dewatering decanter centrifuge is often the first choice for sewage treatment equipment.

Anti-corrosion tips for decanter centrifuges

The most troublesome thing about the decanter centrifuge used in industry is the corrosion that the centrifuge has encountered in the long-term use of chemical raw materials. Now we recommend three ways to avoid or slow down the corrosion of the centrifuge.

The top of the list, the selection of the raw materials for the decanter centrifuge is very important, because different materials and separation requirements require different models. After the model and main parameters are selected, based on the corrosion resistance of different materials in different environments, the physical and chemical characteristics, cost-effectiveness and other factors are summarized, and the strength data of the parts is fundamentally determined. From the perspective of the data itself, its policy materials are safe.

Second, the organization plan of the decanter centrifuge. An excellent plan can extend the service life of the equipment and ensure the safety of the equipment. Regarding structural planning, the simplest plan to accelerate corrosion is the stress concentration tendency and the crevice environment, sometimes even though metal In the immersion solution, the corrosion rate is small; but it constitutes a gap, because the chemical and electrochemical conditions of the internal solution have changed, which will cause severe crevice corrosion.

Third, one of the fundamental ideas for controlling the corrosion of the decanter centrifuge is to block the corrosive environment. In the planning of centrifuges, exterior treatment methods are often used, such as flanges, galvanizing, chrome plating, chemical plating, etc. These methods are useful in many environments, but regarding rotating parts, it is necessary to pay attention to a main appearance: The base material and the coating are two kinds of materials, and their linear expansion coefficients are different. Different deformations will occur when the rotating parts are elastically deformed, and then a lot of micro-cracks will occur; if the aforementioned appearances exist, the corrosion will be accelerated constitute. Therefore, the appearance protection methods of rotating parts should be carefully selected.

GN Clarifying Decanter Centrifuge: Efficient Separation for Complex Materials

Continuous Separation for Higher Efficiency

GN Clarifying Decanter Centrifuge, specifically designed as part of the C series, is engineered to provide continuous separation of suspensions into solids and clarified liquids. Unlike batch separation methods, this centrifuge allows for the uninterrupted feed of material, making it ideal for processes requiring consistent and high-quality separation.

Optimized Design for Better Performance

One of the key features of the C series is its 20-degree beach angle, which contributes to a unique design that optimizes the decanter’s performance. The short cone section of the bowl, designed for dewatering, facilitates the rapid removal of solids, while the longer straight section enhances the clarification process. This design ensures that the centrifuge is particularly effective in handling materials with small particle sizes, low density differences between solids and liquids, moderate viscosity, and moderate concentration.

Tailored for Food and Pharmaceutical Industries

What sets the GN Clarifying Decanter apart is its versatility. The machine can be customized to meet the stringent health and safety standards required in the food and pharmaceutical industries. In these sectors, maintaining hygienic conditions is critical, and GN centrifuges are capable of meeting those requirements. Whether it’s the washing or health protection needs in food processing or pharmaceutical applications, the decanter’s design can be tailored to ensure compliance with industry-specific regulations.

Durable and Corrosion-Resistant Construction

The centrifuge’s construction is another standout feature. The shaft caps at both ends and the bowl are crafted from duplex stainless steel (SUS2205 or SUS2304), which is far superior to the performance of traditional SUS304 and SUS316 stainless steels. This material choice enhances durability and resistance to corrosion, ensuring a longer operational lifespan. The components are manufactured through centrifugal casting and die forging, processes that avoid the issues commonly associated with traditional welding methods, such as intergranular corrosion and residual stress.

Innovative Screw Blade for Enhanced Efficiency

Additionally, GN decanter utilizes a CNC-pressed spiral screw blade, which offers superior performance compared to the traditional drawn screw blades. This blade design improves the efficiency of solid transportation and enhances the press force, resulting in drier solids. The screw blade can also be designed with gradual changes in shape to optimize the efficiency of both transport and pressing, further increasing the performance and productivity of the centrifuge.

Conclusion

In conclusion, GN Clarifying Decanter Centrifuge offers a high-efficiency, customized solution for a wide range of separation applications. Its robust construction, hygienic design, and innovative features make it a reliable and effective choice for industries where performance and compliance are essential.

GNLW654 Mining Tailing Dewatering Centrifuge System to South America

GN Separation has recently completed the manufacturing and factory testing of a tailing slurry dewatering decanter centrifuge system, which is now ready for shipment to a client in South America. Continue reading