A decanter centrifuge is a widely used piece of equipment in laboratories, commonly applied in biology, chemistry, medicine, and various scientific research, education, and production settings. It utilizes the strong centrifugal force generated by the high-speed rotation of the rotor to separate solid particles from liquids or to separate liquid mixtures. It is particularly suitable for the rapid separation and analysis of trace samples.

Monthly Archives: January 2025

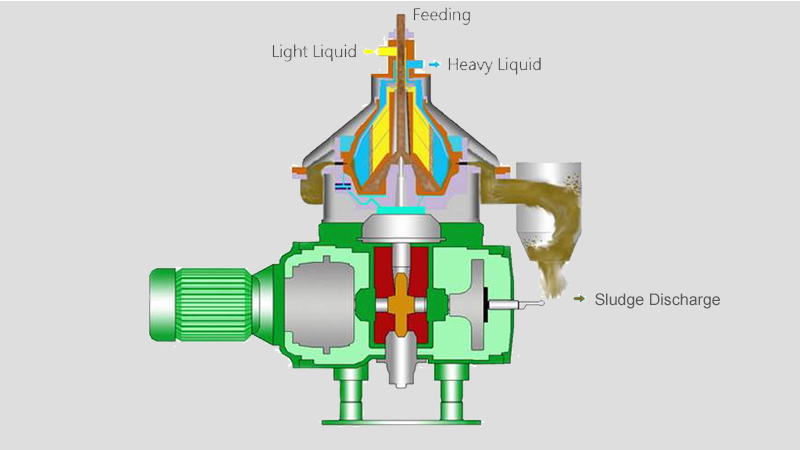

Understanding the Disc Stack Separator: A High-Efficiency Separation Solution

GN disc stack separator is an advanced piece of equipment used for high-speed, efficient separation of three-phase materials—liquid, liquid, and solid. Unlike traditional separators, the three-phase disc separator can simultaneously separate two liquids of different densities while also discharging solid materials. This makes it an essential tool in industries requiring precise separation, such as food processing, chemical engineering, and wastewater treatment.

Superior Separation Efficiency

One of the key advantages of the disc stack separator over other separation technologies, like decanter centrifuges, is its significantly higher G-force. With a G-force of up to 12,000G, compared to the 3,000G of a decanter centrifuge, the disc stack separator ensures a more thorough separation of liquids with different specific gravities, resulting in clearer liquid phases.

How It Works: The Disc Stack Design

The separator features a series of rotating discs, creating separation intervals where the material is processed under strong centrifugal force. The heavier liquid phase moves outward along the disc wall, while the lighter liquid phase moves towards the center. These phases are discharged through separate pumps, and the heavy slag accumulates and is periodically ejected.

Durable and Efficient Construction

Constructed entirely from high-grade stainless steel, the separator minimizes chemical interaction between the material and the machine surfaces. It operates with low noise and minimal energy consumption, thanks to a combination of hydrodynamic coupling and belt or helical gear drives.

Automation for Continuous Production

The PLC-controlled automatic discharge system ensures consistent performance, making it a highly automated, adaptable, and reliable solution for continuous industrial production. The separator also features overload protection, stable speed increases, and easy operation, enhancing its reliability in various industrial settings.

Conclusion: A Valuable Industrial Tool

In summary, GN disc stack separator stands out for its high efficiency, automation, and ability to handle complex separation tasks. Its versatility and reliability make it a valuable addition to any industry requiring precise liquid-solid-liquid separation.

Effective Maintenance and Cleaning of a Decanter Centrifuge

Maintaining the efficiency and longevity of a decanter centrifuge requires a thorough and systematic cleaning process. Here’s how to ensure your centrifuge remains in top condition.

The Importance of a Centrifuge in Dewatering: How It Works and Its Applications

Dewatering centrifuge is a crucial piece of equipment used in many industries to separate solid particles from liquids by applying centrifugal force. The process, commonly referred to as centrifugal dewatering, is especially useful in industries such as wastewater treatment, mining, food production, and even pharmaceuticals.

How Does a Dewatering Centrifuge Work?

At its core, a dewatering centrifuge operates by spinning a slurry (a mixture of solids and liquids) at high speeds. This spinning action generates centrifugal force, which pushes the heavier solid particles outward, while the lighter liquid is forced toward the center. This separation process allows for the efficient removal of water or other liquids, leaving behind solid material that can then be disposed of or further processed.

Applications in Wastewater Treatment

One of the primary applications of dewatering centrifuges is in wastewater treatment plants. Municipalities and industries alike rely on these machines to remove excess water from sludge, reducing its volume and making it easier and more cost-effective to dispose of or recycle. By reducing the moisture content of sludge, centrifuges help in reducing transportation costs, minimizing landfill space, and even recovering valuable resources.

GN dewatering decanter centrifuge is T series decanter centrifuge with beach angle of 8.5 Degrees. GN T series decanter centrifuge is usually used dewatering and thickening purpose. It is widely used for maximum dewatering requirements of municipal and industrial wastewater sludge.

Mining Industry Benefits

In the mining industry, dewatering centrifuges are essential for extracting valuable minerals from slurry produced during extraction processes. The centrifuge helps to recover more of the precious material while also minimizing waste. It also plays a significant role in the dewatering of tailings, reducing environmental impact by preventing water contamination.

The Role in Food Production

Food production is another industry that benefits from dewatering centrifuges. In processes like juice production or the extraction of oils from seeds, a centrifuge helps separate liquids from solids, enhancing the purity of the final product while increasing overall production efficiency.

Pharmaceutical and Chemical Industry Uses

The pharmaceutical and chemical industries also make use of dewatering centrifuges to separate liquids from solid substances during the production of drugs or chemicals. In these sectors, high purity and precision are often essential, and dewatering centrifuges provide an effective solution for removing excess liquids without contaminating the product.

Conclusion

In conclusion, dewatering centrifuges are indispensable in industries that require efficient separation of solids and liquids. GN Sepration is dedicated to solving any difficult separation problems for clients.

Safety Instructions for Decanter Centrifuge

The decanter centrifuge is a high-speed rotating machine, and its safe operation and maintenance are crucial to prevent accidents and equipment damage. Below are essential safety guidelines:

GN Centrifuges in Wastewater Treatment

Centrifuges are vital equipment in wastewater treatment plants, primarily used for dewatering sludge, which is a byproduct of the treatment process. Sludge contains both solid particles and water, and centrifuges help separate the two through rapid spinning. This high-speed rotation creates centrifugal force, pushing denser solids toward the edges while the lighter liquid remains at the center. This separation process helps reduce the volume of sludge, making it easier to handle, transport, and dispose of, which significantly cuts down on operational costs.

How GN Centrifuges Work in Wastewater Treatment

In wastewater treatment, GN centrifuges are used after the primary treatment process when solid particles settle and form sludge. The centrifuge spins the sludge at high speeds, causing the water to be expelled from the solid particles. The result is a concentrated sludge “cake,” which is more manageable for disposal. The liquid removed, often referred to as “centrate,” can be treated and reused in the treatment plant, which helps conserve water and improves overall sustainability.

Benefits of Using GN Centrifuges

Centrifuges offer several advantages in wastewater treatment. They are highly efficient in reducing the volume of sludge, which decreases the need for costly landfill space and transport. Additionally, the recovery of water through centrifugation helps minimize the use of fresh water, supporting sustainability efforts. While the initial investment in a centrifuge can be high, the long-term savings in energy, disposal, and water reuse make it a cost-effective solution. Furthermore, centrifuges are capable of processing various types of sludge, making them a versatile choice for many industries.

Environmental and Operational Impact

The use of centrifuges in wastewater treatment also benefits the environment by reducing the volume of waste sent to landfills. By efficiently separating water from sludge, centrifuges contribute to a cleaner environment and reduce the carbon footprint of wastewater plants. While they do require regular maintenance and occasional pre-treatment of the sludge, their ability to handle large volumes of material quickly makes them indispensable in modern wastewater treatment systems.

In conclusion, centrifuges are an essential technology in wastewater treatment, offering both economic and environmental advantages. They improve the efficiency of sludge dewatering, reduce waste, and help conserve valuable resources, playing a key role in making wastewater treatment more sustainable and cost-effective.